Medical and Medical Aesthetics & Wellness

Section 1: Industry Pain Points

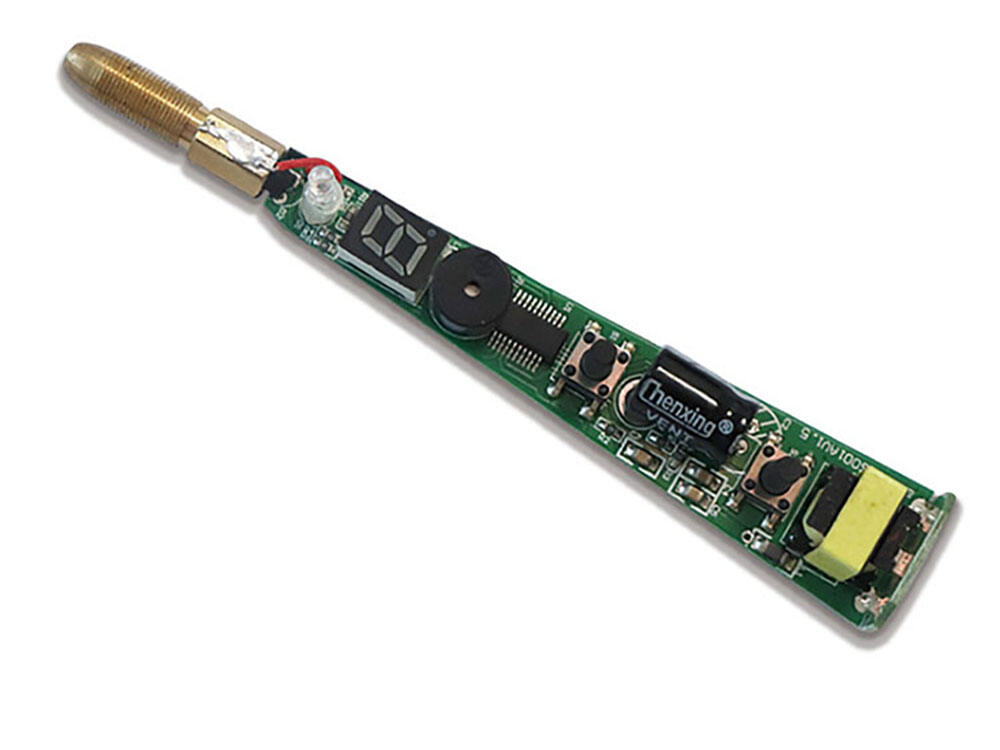

• High Safety and Accuracy: Medical equipment is directly related to life safety, requiring guaranteed signal acquisition accuracy and low noise.

• Strict Regulatory Compliance: Must comply with multiple medical regulations such as ISO13485, FDA, and CE, with high compliance thresholds.

• Long-Term Stability: Must maintain an extremely low failure rate throughout the equipment's lifespan (5-10 years) to avoid downtime risks.

Section 2, Our Industry Solutions

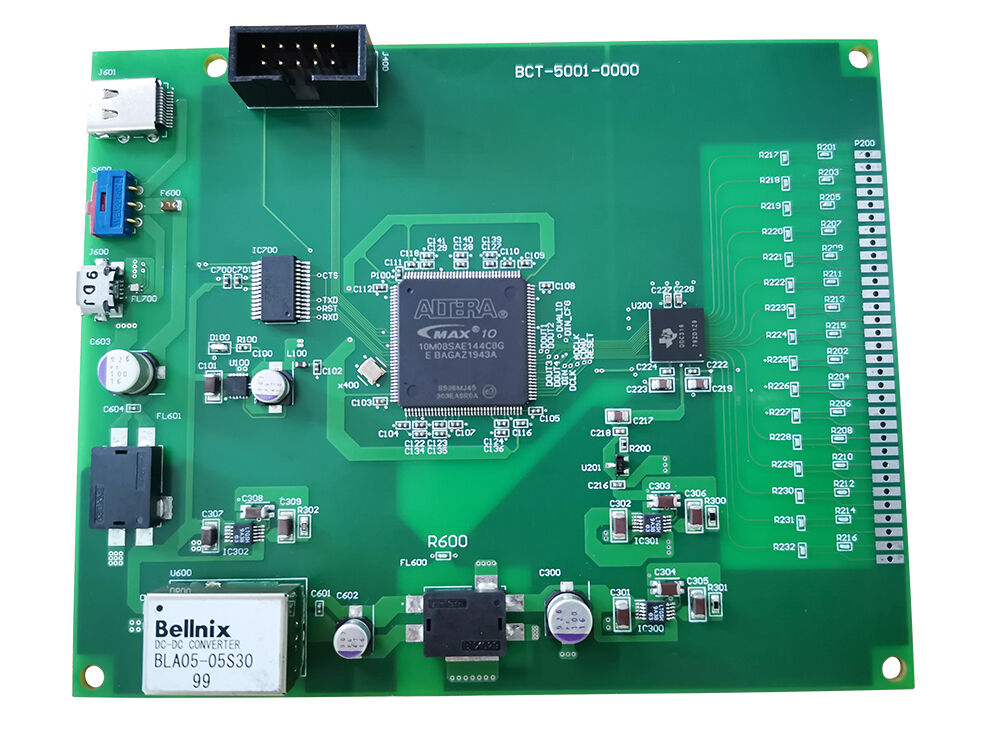

• Aseptic Production Environment: Cleanroom (Class 1000), medical-grade solder (halogen-free), compliant with IPC-A-610 Class 3 standards

• End-to-End Traceability System: Establishing a complete traceability system from supplier qualification verification and batch number recording to production process parameters, testing data, and operator records.

• Rigorous Quality Testing: Performing FDA-approved reliability testing, including multiple stages such as accuracy testing, sterility testing, and aging testing, ensuring zero-defect product delivery throughout the entire process.

Section 3, Real-world Project Cases

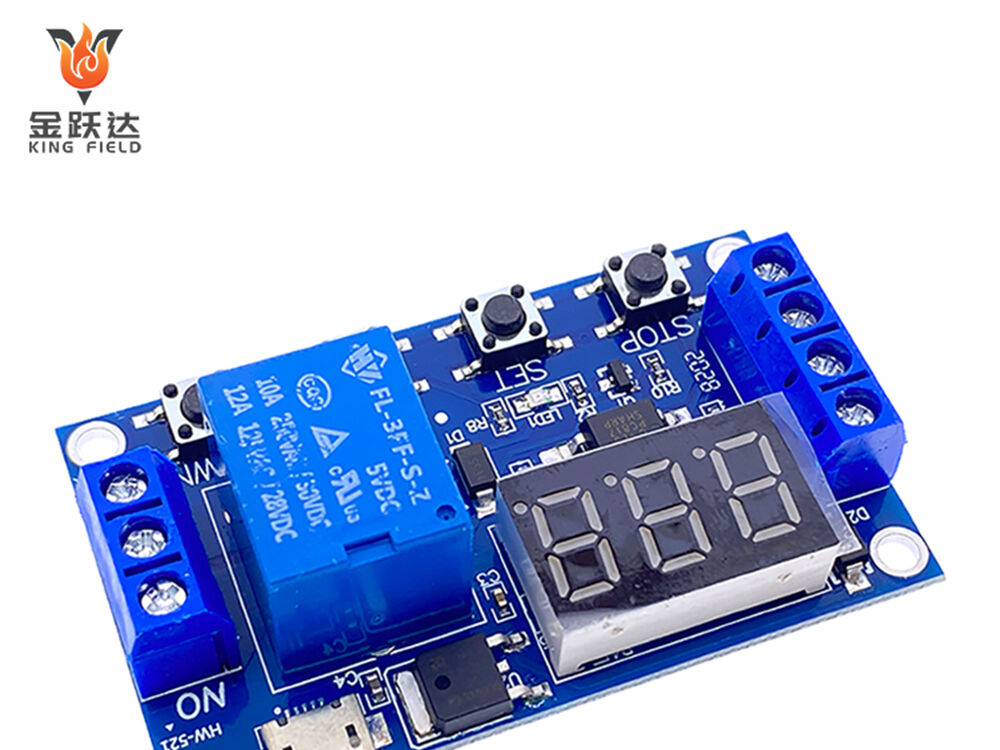

Portable In Vitro Diagnostic Equipment: We provide PCBA assembly services for diagnostic instruments. The delivered PCBAs have passed FDA testing with a 100% pass rate, helping clients quickly pass regulatory approvals. They have been applied in batches to 20+ top-tier hospitals with zero complaints and zero incidents.

Section 4, Authoritative Certifications

• ISO 13485 Medical Device Quality Management System Certification, IPC-A-610 Level 3; all processed materials have passed FDA biocompatibility testing.

• US FDA Medical Regulations Compliance Certification

• EU CE Medical Device Certification

• 20+ years of experience in medical PCBA processing, equipped with a Class 10,000 cleanroom and medical-grade testing equipment.

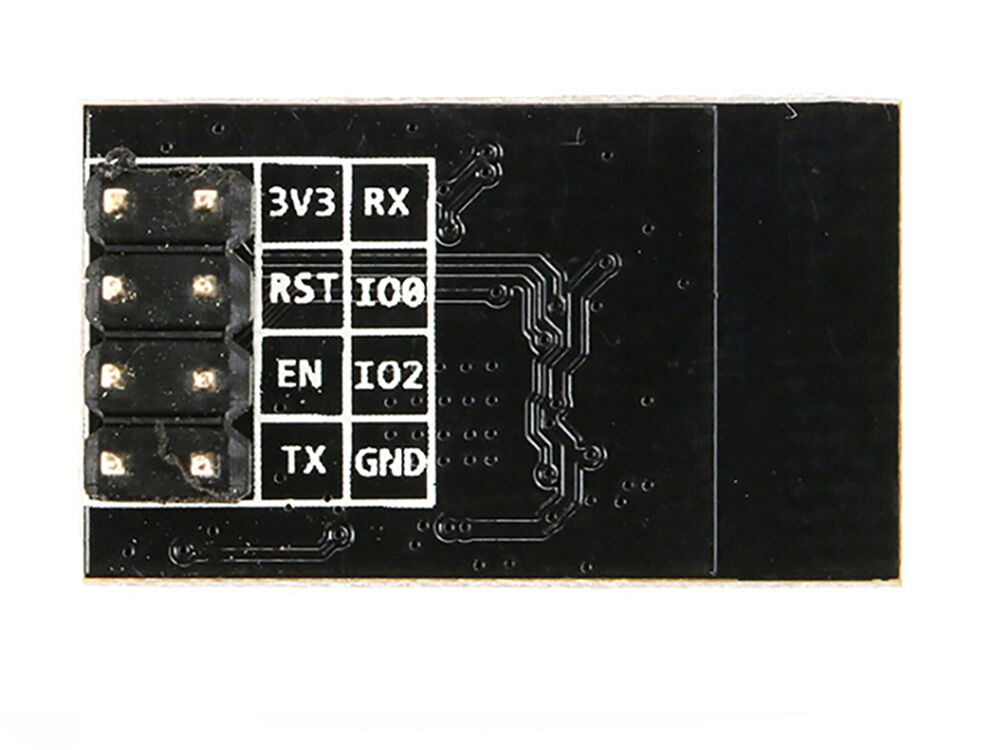

| 5 technical indicators | 1. Mounting accuracy: ±0.01mm, meeting the precision assembly requirements of micro medical devices. | |

| 2. Biocompatibility: Nickel-containing processes are prohibited in surface treatment; gold plating layer thickness >1.27μm. | ||

| 3. Aseptic standard: Manufactured in a Class 8, 10,000 cleanroom, with aseptic control throughout the process. | ||

| 4. Aging test: Failed to withstand 2000 hours of salt spray + 85℃ high-temperature aging test. | ||

| 5. Signal accuracy: ADC effective bit depth ≥20 bits. | ||

| 3 industry pain points | 1. Medical equipment is directly related to life safety, requiring guaranteed signal acquisition accuracy and low noise. | |

| 2. It must comply with multiple medical regulations such as ISO13485, FDA, and CE, and has high requirements for material biocompatibility. | ||

| 3. The equipment must maintain an extremely low failure rate throughout its lifespan (5-10 years) to avoid downtime risks. | ||