Industrial Control

Section 1: Resonance with Industry Pain Points

• Automotive-grade compliance requirements are stringent.Lack of professional certification.Difficulty in entering the OEM supply chain;

• Strong electromagnetic interference and large temperature and humidity fluctuations in industrial environments pose challenges for PCBA products, Insufficient stability and anti-interference ability

• Long product lifecycle, Long-term operational reliability and continuous material supply must be guaranteed.

Section 2, Our Industry Solutions

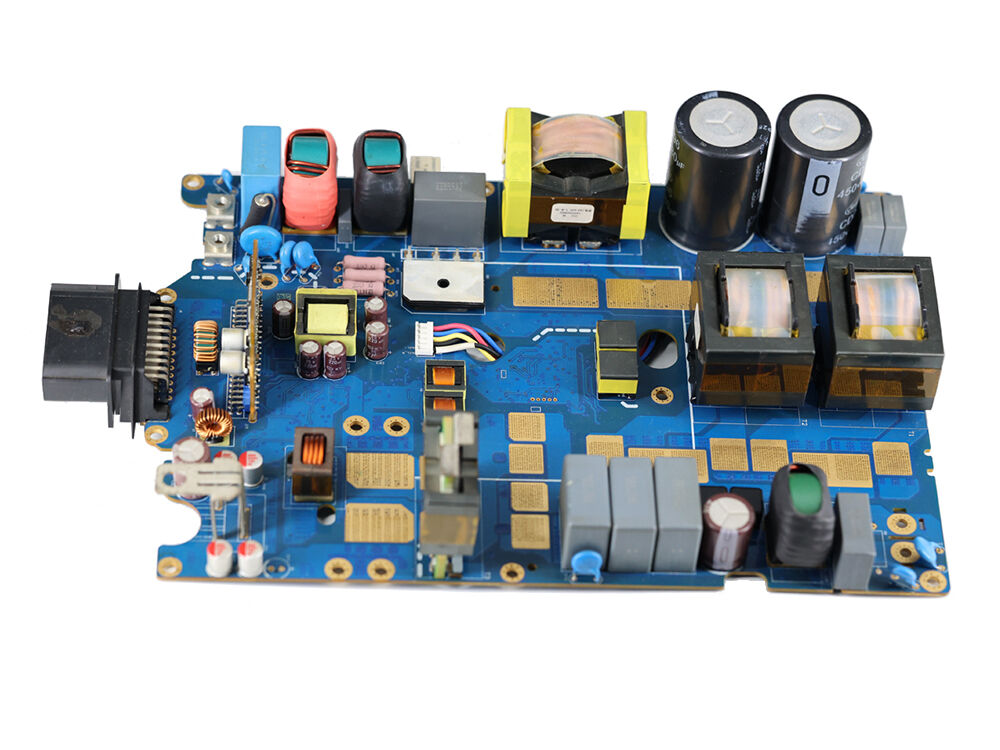

• Full-process quality control: Based on the ISO9001 system, production parameters are monitored in real time through the MES system, establishing a full-process traceability record from material warehousing to finished product delivery.

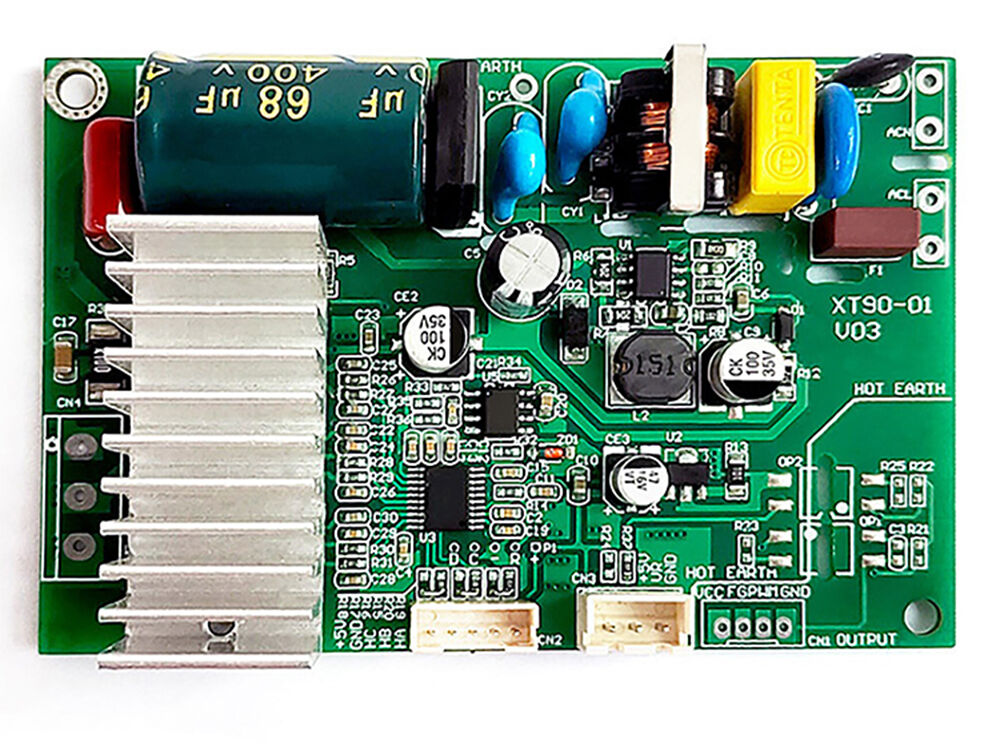

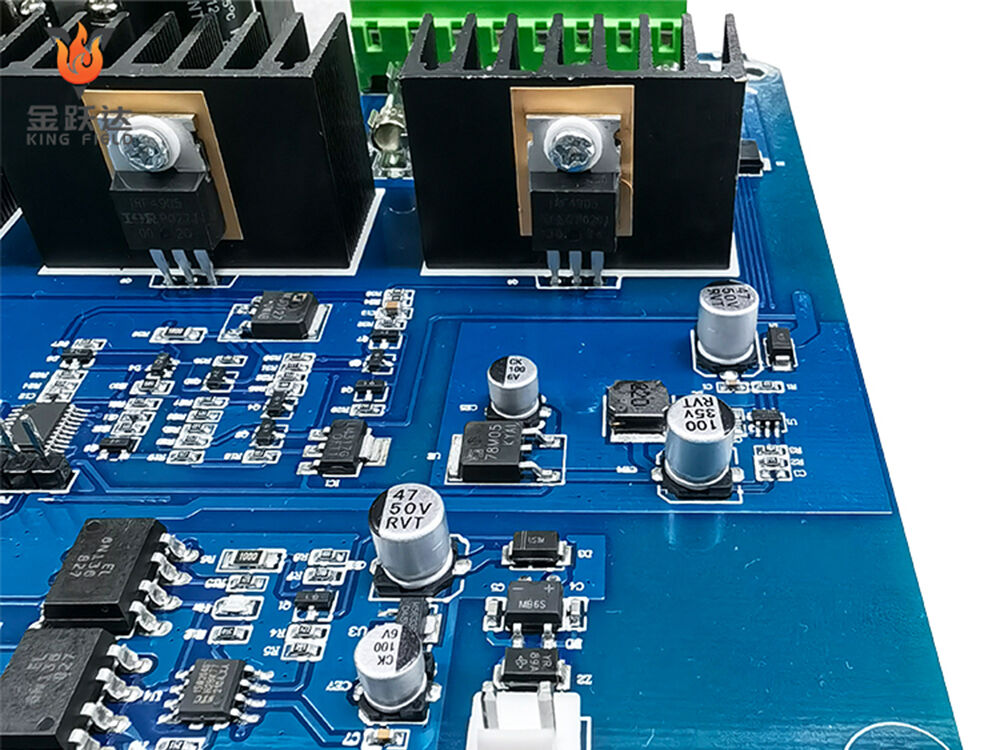

• Environmental adaptation optimization: Utilizing high Tg sheet with redundancy design, critical signal lines. Reserve parallel routing, pairing electromagnetic compatibility optimization. Solution to enhance adaptability to complex environments -

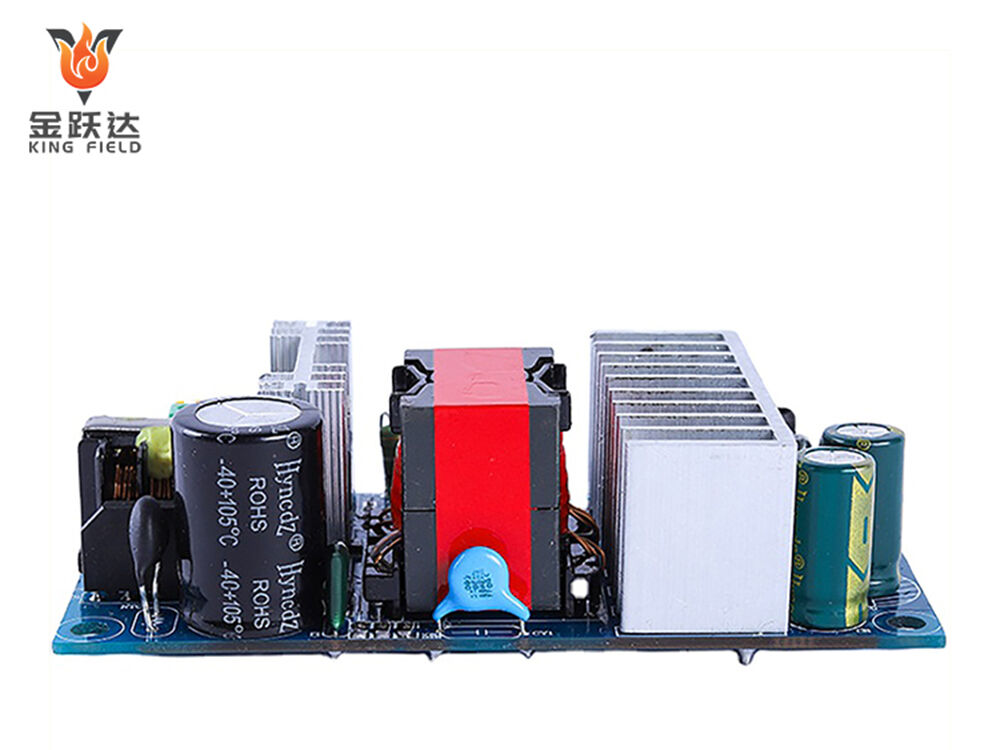

• Manufacturing stage: Precision SMT placement, protected by conformal coating. It supports the IPC-A-610 Class 3 standard.

Section 3, Real-world Project Cases

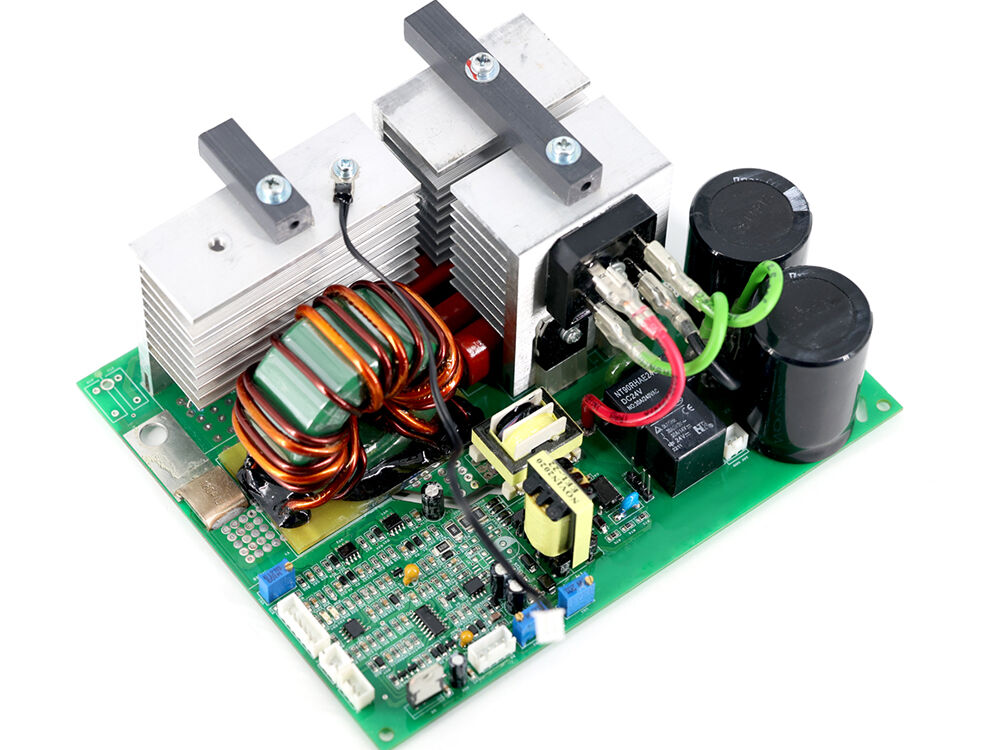

Heavy Machinery Plant: Providing PLC control board PCBA services, Kingfield responded quickly to multi-model switching needs through flexible production scheduling, optimized PCB grounding design and conformal coating process, ultimately enabling continuous operation of the products. 6000 hours without failure The pass rate reached 99.8%.

Section 4, Authoritative Certificates

• ISO9001 quality management system certification ISO 14001 environmental management system IPC-A-610 Class 3 industry standard certification

• UL94 V-0 flame retardant certification

• EMC Electromagnetic compatibility testing and certification

• Services for 200+ companies. Repurchase rate 85%

| 5 technical indicators | 1. Operating temperature range: -40℃~125℃,it meets the needs of complex temperature and humidity environments in industry. | |

| 2. Electromagnetic compatibility (EMC) rating: pass IEC 61000-4-4 Level 4 standard, radiated interference attenuation ≥30dB. It has strong resistance to electromagnetic interference. | ||

| 3. Copper foil thickness: ≥3oz, this improves high current carrying capacity and heat dissipation performance. | ||

| 4. Continuous trouble-free operation time: ≥100,000, hourly rate of critical signal disconnection <0.01%. | ||

| 5. Three-proof coating standard: Nanoscale conformal coating thickness ≥25μm, it can withstand high humidity environments of 85%. | ||

| 3 industry pain points | 1. Real-time performance and accuracy: Industrial control systems have extremely high requirements for signal processing accuracy and response speed. Avoid electromagnetic interference (EMI) question. | |

| 2. High reliability requirements: Industrial control equipment often operates in harsh environments (such as high temperature, high humidity, and vibration), which can easily lead to PCBA failure. | ||

| 3. Long lifecycle requirements: Industrial equipment needs to operate stably for a long time (10-15 years), and there are significant challenges in component supply chain management and compatibility. | ||