Robot Assembly

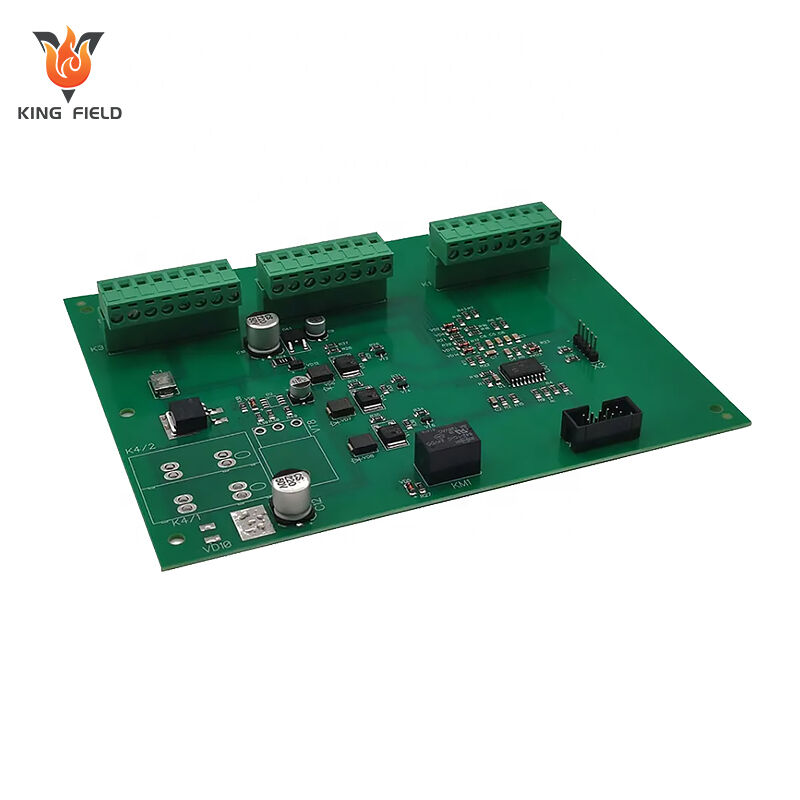

Precision Robot Assembly for PCB manufacturing—ideal for medical, industrial, automotive & consumer electronics. Automated high-speed placement, consistent quality, and scalable production. Paired with DFM support, AOI/X-ray testing, and fast delivery—boost efficiency, cut costs, and ensure reliable assemblies.

✅ Automated high-precision placement

✅ Strict quality control

Description

Overview of Robot Assembly Applications in the PCBA Industry

Robot assembly refers to the automation of the entire PCBA process or key operations through automated robotic systems, covering core aspects such as component placement, soldering, testing, insertion, and packaging. As a core component of intelligent manufacturing, robot assembly has become a key technological support for Kingfield to improve PCBA production efficiency, ensure product consistency, and adapt to the needs of high-end manufacturing. Its application spans the entire lifecycle from prototyping to mass production, driving the PCBA industry's transformation from "labor-intensive" to "technology-intensive."

I. Core Application Scenarios of PCBA Robot Assembly

1. High-precision component mounting

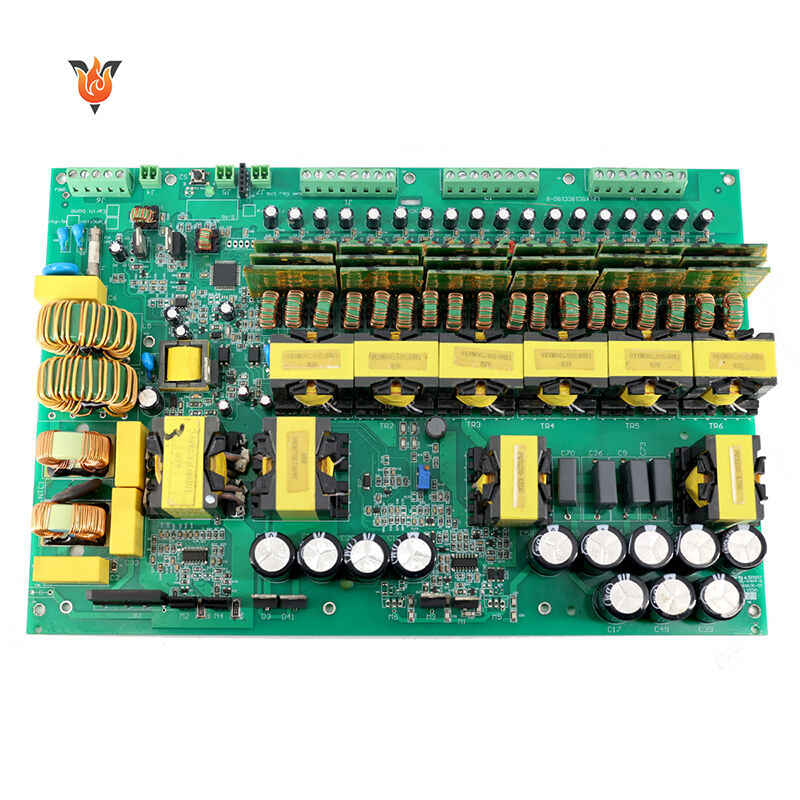

Robot assembly is most widely used in the SMT process, with core equipment including automated systems such as pick-and-place machines and solder paste printers. For high-precision packaged devices such as ultra-miniature components, BGA, and QFP, robots achieve precise placement through vision positioning technology, with placement speeds reaching over 100,000 points per hour, far exceeding manual efficiency. It is compatible with Kingfield's production needs for high-density PCBs, Mini LED driver boards, and other high-end products, avoiding problems such as component misalignment, reverse placement, and missed placement caused by manual placement, and significantly improving placement yield.

2. Automated welding and interconnection

Robotic soldering is a key process for ensuring the reliability of electrical connections in PCBAs.

Mainstream technologies include:

· Reflow soldering robots: These achieve batch component soldering through precise temperature control profiles, avoiding problems such as cold solder joints, bridging, and overheating damage common in manual soldering.

· Selective wave soldering robots: These precisely spray solder through programmable nozzles for through-hole components, adapting to hybrid assembly (SMT+THD) PCBA products and improving soldering consistency.

· Laser soldering robots: Used in high-precision, high-reliability scenarios, these robots have a small heat-affected zone and are suitable for soldering tiny solder joints and heat-sensitive components.

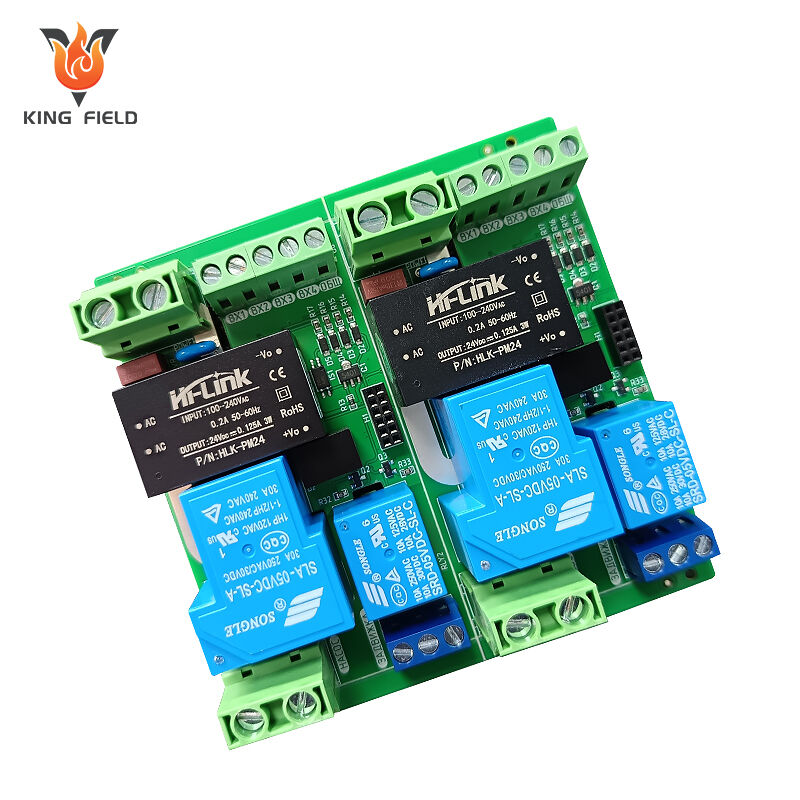

3. Automation of insertion and assembly

For through-hole devices that require manual insertion, the robotic assembly system achieves automated insertion through a combination of robotic arms and fixtures:

It supports flexible switching between multiple device types and adapts to the insertion requirements of different PCBA products through programmable logic; It solves problems such as low efficiency, high labor intensity, and device damage caused by uneven insertion force in manual insertion, and is especially suitable for Kingfield in mass production scenarios such as industrial control boards and power boards.

4. Automated testing and quality control

The deep integration of robotic assembly and inspection technologies forms a closed loop of "assembly-inspection":

· Visual inspection robot: Automatically identifies issues such as placement misalignment, soldering defects, and missing components using AI vision algorithms. Inspection speed is 5-10 times faster than manual inspection, with a false positive rate of less than 0.1%;

· In-Circuit Testing (ICT) robot: Automatically performs electrical performance testing on PCBAs, uploading data to the MES system in real time for quality traceability;

· X-ray inspection robot: Detects hidden solder joint defects on the bottom solder joints of BGA, CSP, and other packaged devices using X-ray penetration inspection, ensuring the quality of highly reliable products.

5. Back-end packaging and final assembly

In the back-end processes of PCBA, robotic assembly is responsible for operations such as shell packaging, connector insertion and removal, and cable soldering: Collaborative robots work in tandem with humans to complete complex processes such as heavy shell assembly and precision cable soldering, balancing flexibility and accuracy; Adapting to Kingfield's customized needs, supporting rapid switching of multiple varieties and small batches of products, and shortening product delivery cycles.

II. Core Advantages of Robot Assembly

1. Efficiency Improvement: Breaking Through the Bottleneck of Manual Productivity

The robots can operate 24 hours a day without fatigue or emotional disturbance. The capacity of a single robot assembly line is 3-5 times that of a manual production line. For bulk orders, "unmanned production" can be achieved through the collaboration of multiple robots, which can significantly shorten the production cycle and help Kingfield respond quickly to customer delivery needs.

2. Quality Assurance: Continuously improving product consistency

Robot assembly boasts superior repeatability and operational stability compared to manual assembly, controlling defect rates such as placement deviations and soldering defects to within one in a million. Through digital programming and parameter solidification, it ensures that the production standards of each PCBA are completely consistent, making it particularly suitable for industries with extremely high reliability requirements, such as automotive electronics and medical equipment, thus strengthening Kingfield's reputation for quality.

3. Cost optimization: Long-term reduction of overall production costs

Although the initial investment in robots is high, in the long run, they can significantly reduce costs:

• Labor costs: Reduce reliance on skilled workers, lowering recruitment, training, and management costs;

• Loss costs: Reduce component damage and PCB scrapping caused by manual operation, lowering material loss rates;

• Management costs: Real-time monitoring of production data through the MES system optimizes production scheduling and reduces capacity waste.

4. Flexible production: adaptable to diverse and customized needs.

Modern robotic assembly systems support rapid programming and changeover. For Kingfield's customized PCBA business, production line parameters can be adjusted within 1-2 hours without large-scale equipment modifications, enabling efficient production of "small batch, multiple batches" orders and improving market responsiveness.

5. Safety Upgrade: Mitigating Production Safety Risks

The production process of PCBA involves potential risks such as soldering, high temperature, and chemicals. Robot assembly can replace human labor to complete high-risk processes and reduce the risk of workplace injuries. At the same time, collaborative robots have collision detection functions and can work safely with humans, balancing production efficiency and operational safety.

III. Technical Features and Application Value of Kingfield Robot Assembly

Based on its technological expertise and customer needs in the PCBA industry, Kingfield has developed a "customized + intelligent + integrated" robot assembly solution:

• Customized Adaptation: Optimizing robot assembly parameters to suit the characteristics of PCBA products in different industries;

• Intelligent Integration: Integrating AI visual inspection, MES production management system, and digital twin technology to achieve real-time monitoring, data traceability, and intelligent optimization of the production process;

• Integrated Service: Providing full-process services from robot selection, production line setup, programming and debugging to post-maintenance, helping customers quickly implement automated production and lowering the technical barriers. Through the deep application of robot assembly technology, Kingfield not only achieves a dual improvement in production efficiency and product quality but also provides customers with "efficient, reliable, and customized" PCBA solutions, strengthening its core competitiveness in the high-density, high-reliability, and customized PCBA field and driving the industry's intelligent manufacturing upgrade.

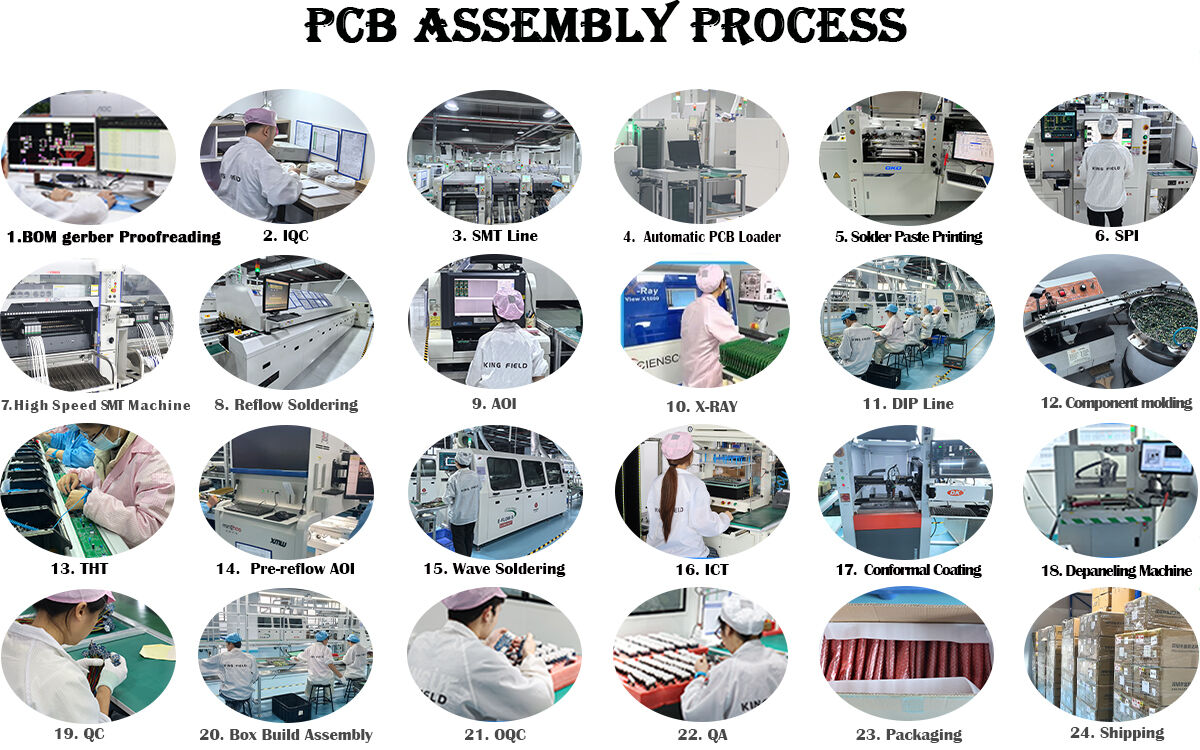

Assembly Process

Robot PCB Assembly Process Step-by-Step Overview

Robotic PCB assembly is an automated process that integrates precision mechanics, visual positioning, and intelligent control. Its core revolves around a closed loop of "precise positioning - component handling - precise assembly - quality inspection." The following is a standardized, step-by-step breakdown, aligning with actual industrial production logic:

1. Preliminary preparations:

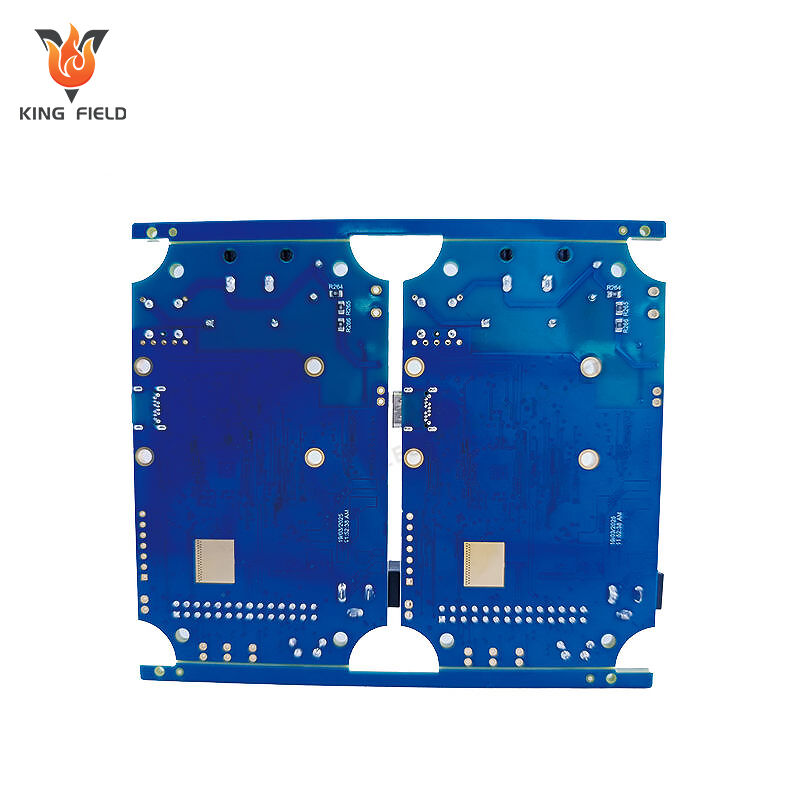

· PCB Cleaning and Positioning: The robot receives the PCB board via an automated loading module. It first undergoes plasma cleaning or brush dust removal to remove oil and dust from the solder pads. Then, the PCB is fixed on a carrier, and the PCB coordinate system is calibrated using reference point visual recognition to ensure assembly reference accuracy.

· Parameter Presetting and Program Import: Based on the PCB design documents, parameters such as component coordinates, package specifications, and assembly sequence are imported into the control system. The robot presets its motion path through offline programming or teach-in mode to avoid interference risks.

· Material Preparation: Surface mount components are loaded onto conveyor belts, trays, or tubular racks. After the material detection module confirms the component model and orientation are correct, the components are transported to the robot's picking station.

2. Core Assembly: Component Pick-up - Positioning - Assembly

Step 1: Component Pickup The robotic arm is equipped with a vacuum nozzle or gripper and automatically switches to the appropriate tool according to the size of the component. It uses a vision system to identify the position and orientation of the components on the rack and picks up the components accurately, avoiding damage or falling of the components.

Step 2: Component orientation correction After being picked up, the components undergo secondary identification by the vision inspection module to correct any offset or rotation angle, ensuring precise alignment between the pins and PCB pads, especially suitable for high-density packaged components such as BGA and QFP.

Step 3: Precision Assembly The robot moves along a preset path to the corresponding pad position on the PCB and places the component smoothly or inserts it into the pad hole. In the surface mount process, after the component is attached to the pad, the vacuum nozzle releases pressure. In the through-hole process, the robotic arm assists in fully inserting the component pins to ensure good contact.

Step 4: Welding and curing For SMT assembly, the assembled PCB is transported to a reflow oven where solder paste is cured at high temperatures to achieve electrical connection between the components and the PCB. The robot can be equipped with an online soldering module to complete wave soldering or spot soldering of through-hole components.

3. Quality Inspection: Real-time Verification and Defect Removal

· Online Visual Inspection (AOI): After robot assembly, the AOI inspection equipment automatically scans the PCB, compares it with standard images, and identifies defects such as missing components, incorrect components, misalignment, and cold solder joints, with inspection accuracy down to the micron level.

· Electrical Performance Testing: Through bed-of-needle testing or flying probe testing modules, the PCB circuit's electrical parameters such as conductivity and insulation are tested, eliminating hidden faults.

· Defect Handling: Detected defective products are automatically marked and transported to the rework station, while qualified products proceed to the next process, achieving an automated closed loop of "assembly-inspection-sorting".

4. Subsequent Processes: Finished Product Processing and Data Traceability

• PCB Cleaning and Protection: Qualified products undergo dust removal and conformal coating, followed by a visual re-inspection to ensure no residual impurities or assembly defects.

• Automated Unloading and Packaging: Robots remove assembled PCBs from carriers and neatly stack them in batches into bins or conveyor lines, awaiting subsequent packaging processes.

• Data Recording and Traceability: Assembly parameters are collected throughout the process and synchronized to the MES system to generate production reports, supporting full product lifecycle traceability and facilitating process optimization and quality control.

Manufacturing capacity

| Equipment manufacturing process capability | |||||

| SMT Capacity | 60,000,000 chips/day | ||||

| THT Capacity | 1,500,000 chips/day | ||||

| Delivery time | Expedited 24 hours | ||||

| Types of PCBs Available for Assembly | Rigid boards, flexible boards, rigid-flex boards, aluminum boards | ||||

| PCB Specifications for Assembly | Maximum size: 480x510 mm; Minimum size: 50x100 mm | ||||

| Minimum Assembly Component | 01005 | ||||

| Minimum BGA | Rigid boards 0.3 mm; Flexible boards 0.4 mm | ||||

| Minimum Fine-Pitch Component | 0.2 mm | ||||

| Component Placement Accuracy | ±0.015 mm | ||||

| Maximum Component Height | 25 mm | ||||