Turnkey PCB Assembly

All-in-one Turnkey PCB Assembly—from component sourcing to final testing for medical/industrial/automotive/consumer electronics. We handle BOM management, PCB fabrication, SMT/BGA assembly, and strict quality checks for 1–1000+ units. 24h prototyping, fast delivery, and DFM support—save time, cut hassle, and get ready-to-use PCBs.

✅ End-to-end component sourcing & assembly

✅ 24h prototyping | scalable production

✅ DFM optimization & multi-stage testing

✅ Hassle-free, on-time delivery

Description

Turnkey PCB Assembly

Turnkey PCB Assembly is a one-stop printed circuit board manufacturing and assembly solution. Its core function is to provide clients with a fully managed service from project initiation to finished product delivery. Clients only need to specify their final product requirements, eliminating the need to deal with multiple suppliers. The service covers component procurement, PCB manufacturing, PCB assembly, testing and inspection, packaging, and delivery, helping clients simplify project management processes, shorten product cycles, and reduce supply chain risks. It is particularly suitable for companies lacking supply chain resources or those wishing to focus on their core business. The term "turnkey" originates from the concept of providing a complete, ready-to-use solution. A turnkey project refers to any product or service delivered to the buyer that can be used immediately. In the PCB assembly field, this means that the buyer receives a fully assembled and tested circuit board without managing multiple suppliers or coordinating various manufacturing stages.

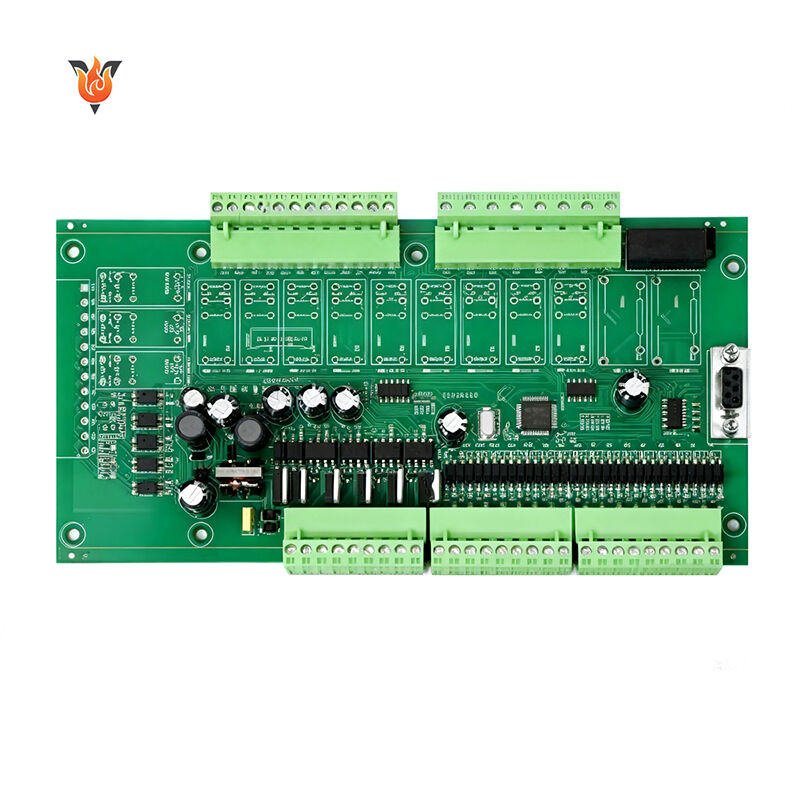

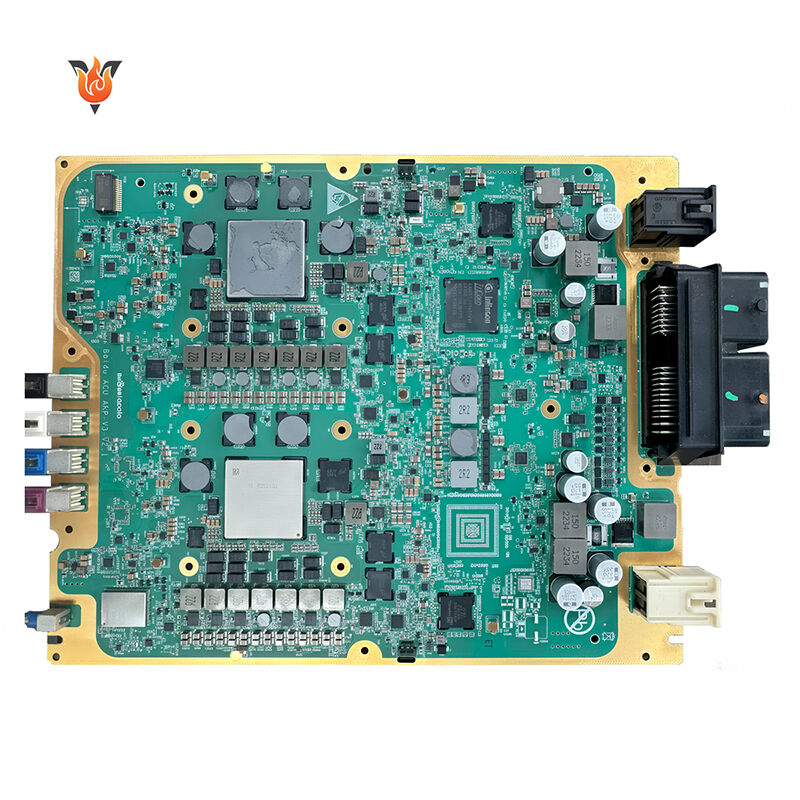

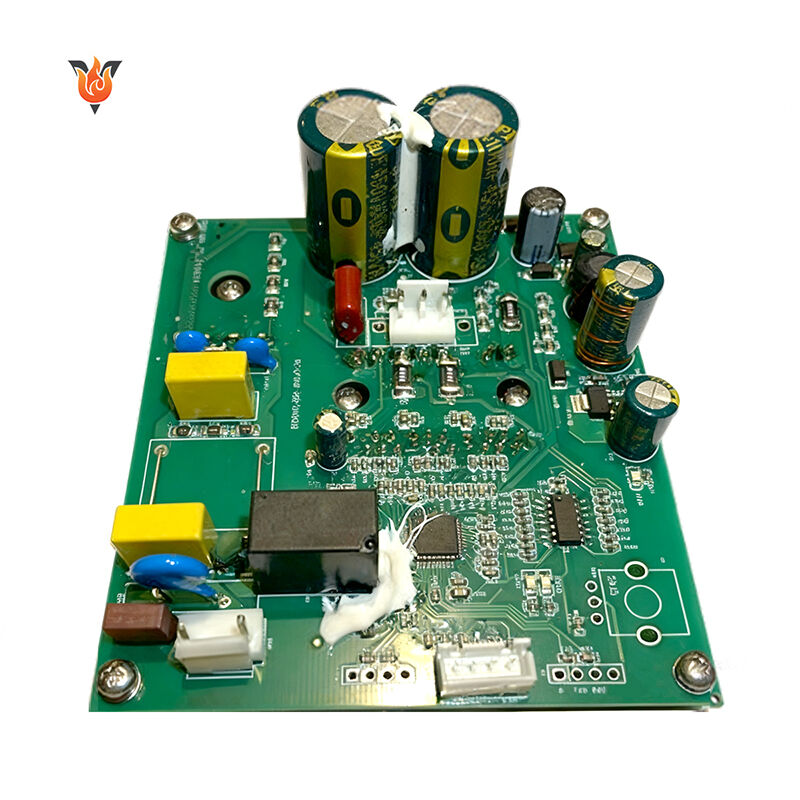

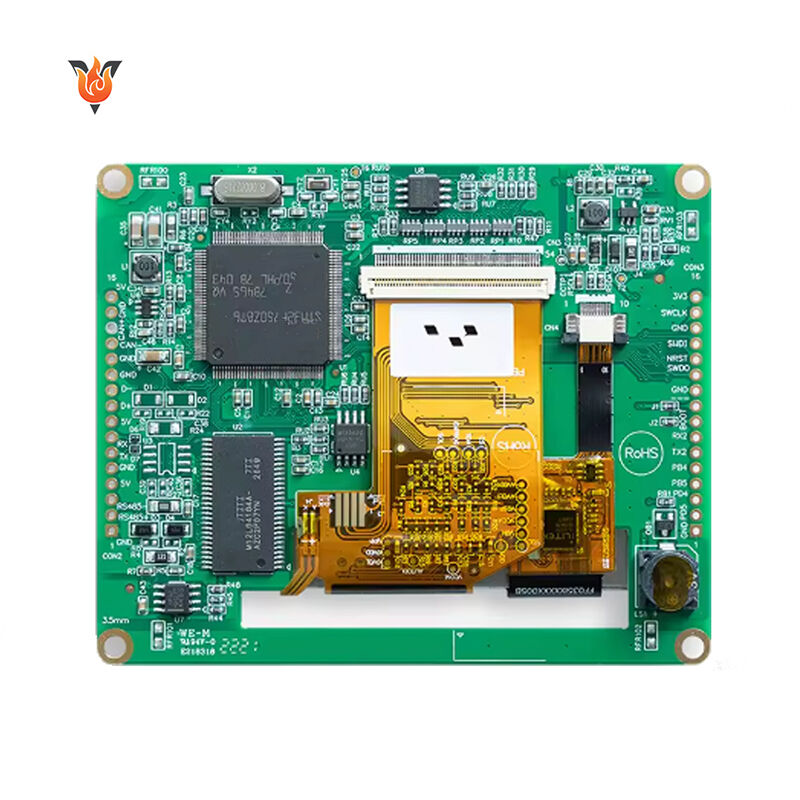

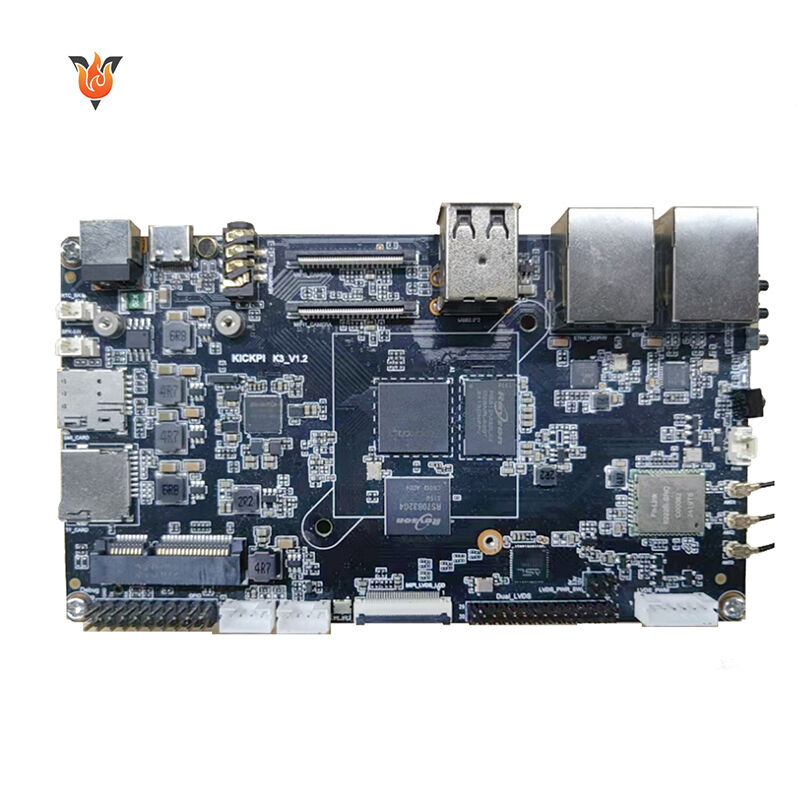

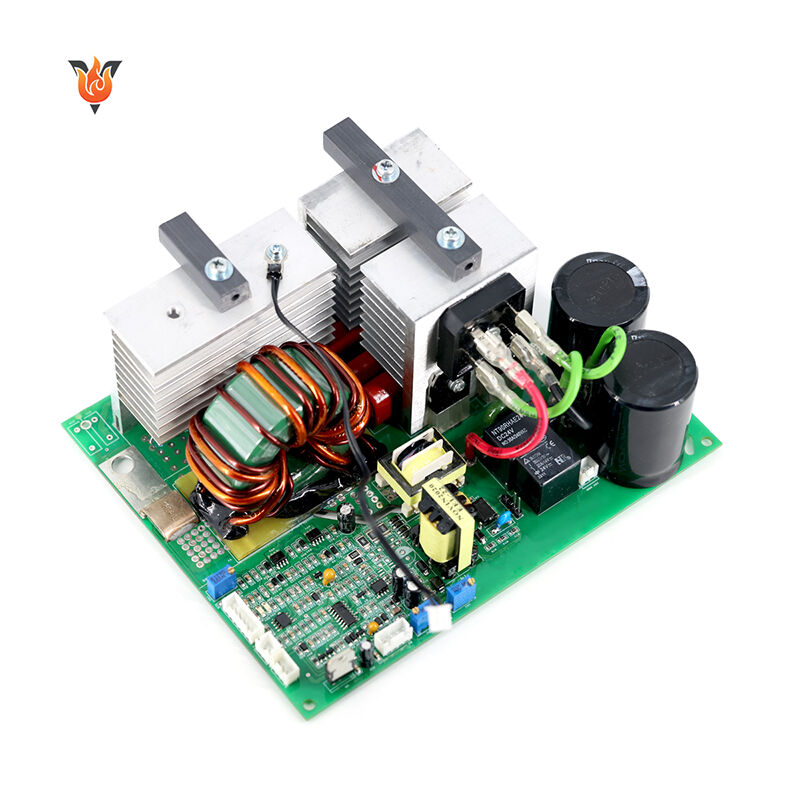

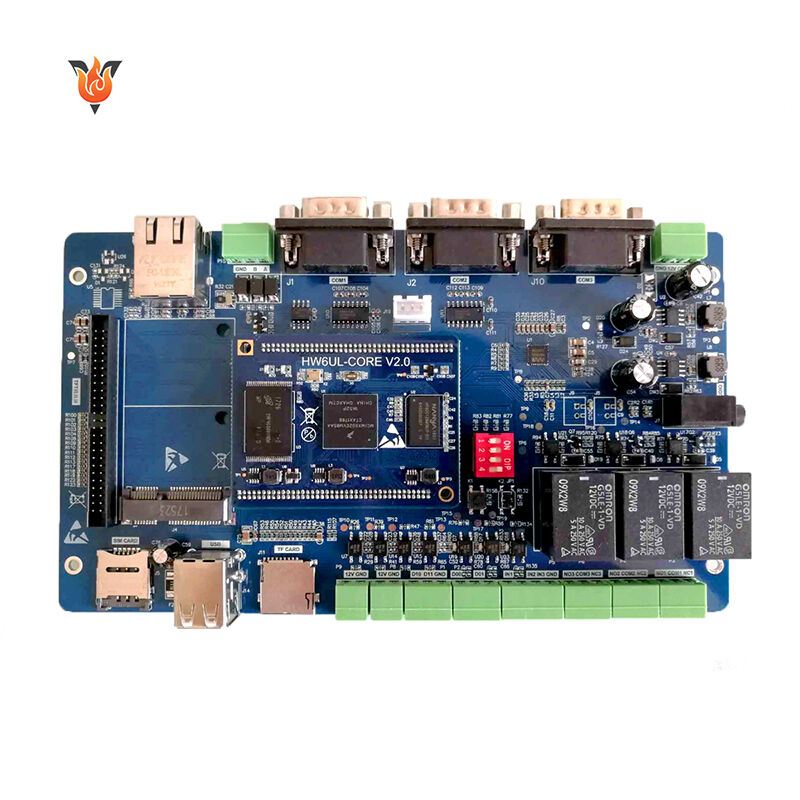

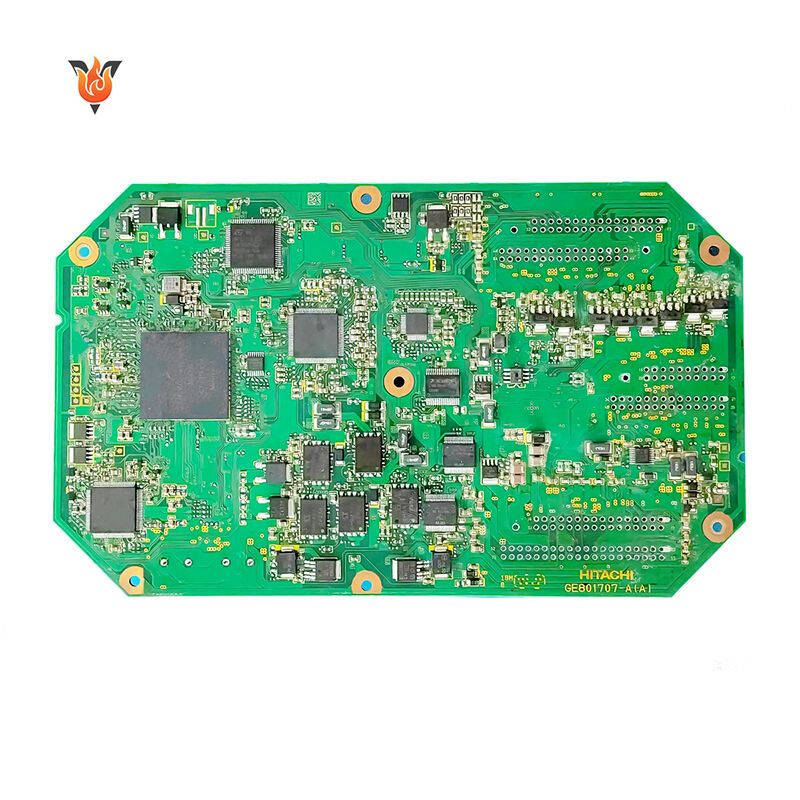

| Turnkey PCBA We Served | |||||

|

|

|

|||

| Industrial Equipment Control Turnkey PCBA | Communication Base Station Control PCB Board | Power Inverter PCBA | |||

The Benefits of Turnkey PCB Assembly for Businesses

Simplified Management, Focus on Core Business:

Enterprises no longer need to separately handle multiple partners such as PCB manufacturers, component suppliers, and testing institutions. They only need to communicate requirements and coordinate progress with a single service provider, significantly reducing the time and manpower costs of supply chain management. This allows enterprises to free themselves from cumbersome production support tasks and concentrate resources and energy on core businesses, enhancing their core competitiveness.

Shortened Cycles, Accelerated Product Launch:

Service providers possess mature supply chain systems and production processes, enabling efficient integration of component procurement, PCB manufacturing, assembly, and testing. This avoids process delays caused by multiple inter-stage coordination. Simultaneously, professional service providers can quickly respond to unexpected situations in production, significantly shortening the product cycle from R&D prototyping to mass delivery, helping enterprises seize market opportunities.

Reduced Costs and Risks:

Cost Optimization: Many PCB suppliers offer this service at reasonable prices. When someone buys PCB components separately, they must pay for shipping, making production response costs high. However, if you have a complete turnkey assembly, you will use low-cost production. Because of its large-scale procurement advantages, Kingfield can obtain components at more favorable prices and reduce unit manufacturing costs by integrating the production process; at the same time, it reduces the fixed asset investment and operating costs of companies building their own supply chains, warehousing, and production teams.

Risk Management: Professional service providers have extensive experience in component quality verification, supply chain stability control, and production process compliance, effectively avoiding potential risks such as material quality defects, supply chain disruptions, and substandard production processes, ensuring product qualification rates and delivery stability.

Enhancing Product Quality and Professionalism:

Kingfield possesses professional production equipment, a mature process technology team, and standardized testing procedures. It can strictly control every production link according to industry standards and customer needs, accurately identifying assembly defects. Compared to companies building their own production teams, this ensures greater stability and professionalism in product quality, making it particularly suitable for electronic products with high requirements for process precision and quality.

Why choose our Turnkey service?

We offer end-to-end services from design optimization to finished product delivery, allowing you to focus on product innovation without worrying about the production process.

Fast delivery: Small-batch sampling delivered in 3-5 days, mass production in 5-7 days, with priority production for urgent orders to help you accelerate your product launch.

Quality assurance: Comprehensive quality control throughout the entire process, from material procurement to finished product delivery, ensures product reliability and consistency through rigorous testing at every step.

Cost optimization: Leveraging supply chain advantages and process optimization, we help you reduce material and production costs, enhancing your product competitiveness.

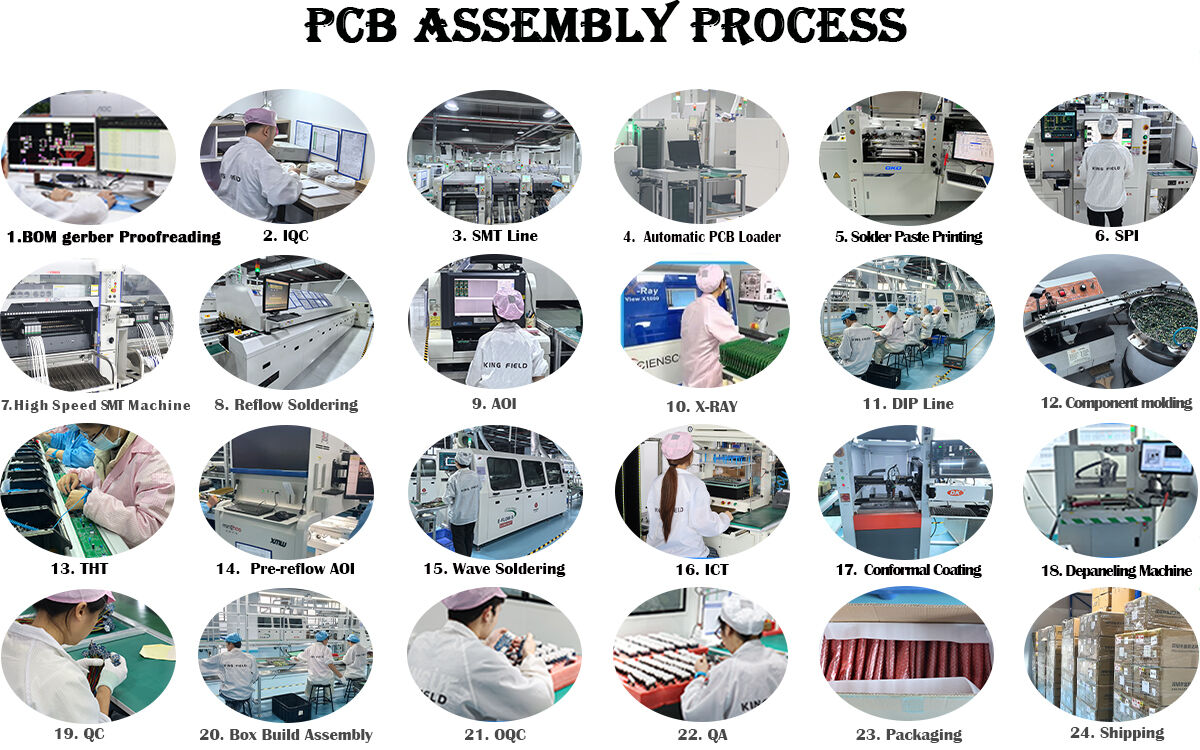

Turnkey PCB Assembly Process

• Requirements Coordination and Solution Confirmation: The client provides design documents and product requirements . The service provider assesses technical feasibility, optimizes the design (such as DFM manufacturability analysis), confirms material selection, process solutions, and quotations, and both parties reach a consensus on cooperation.

• Component Procurement and Management: The service provider is responsible for component procurement based on the BOM list, obtaining materials through compliant channels, conducting quality verification, and managing inventory to ensure that materials match PCB specifications and assembly requirements, avoiding shortages or incorrect materials.

• PCB Manufacturing: PCB boards are manufactured according to the confirmed design parameters, covering processes such as substrate cutting, circuit etching, solder mask printing, silkscreen printing, and drilling. After completion, PCB quality is verified through AOI and other methods to ensure compliance with assembly standards.

• PCB Assembly: Includes solder paste printing (SMT process), component placement, and reflow soldering . For through-hole components, through-hole and wave soldering are performed to ensure a secure connection between the components and the PCB.

• Inspection and Testing: After assembly, AOI/AXI is used to check for soldering defects. Functional testing and aging testing are performed to ensure normal product functionality.

• Post-Processing and Delivery: Qualified products are cleaned, repaired, packaged, and finally delivered to the customer according to the agreed method. Some service providers also offer after-sales technical support and quality traceability services.

FAQ

Q: What is the difference between turnkey and consignment assembly?

A: In turnkey assembly, the manufacturer provides all parts. In consignment assembly, you provide the components, and the manufacturer only handles the assembly.

Q: How long does turnkey PCB assembly take?

A: Delivery time typically ranges from 5-10 days for prototyping to 3-6 weeks for mass production, depending on complexity and component availability.

Q: What documents are required for turnkey PCB assembly?

A: You will need Gerber files, drilling files, Bill of Materials (BOM), assembly drawings, and test specifications.

Q: What quality inspections are performed?

A: Routine inspections include AOI visual inspection, X-ray inspection (for BGA), and functional testing, some of which follow IPC-A-610 standards.

Q: How are component replacements handled?

A: Kingfield provides replacement suggestions with specifications, and replacements are only made after customer approval. A 5% spare component reserve is maintained for some components.