Box Build Assembly

End-to-end box build assembly for complete electronic products—integrating PCBA, cables, enclosures, and accessories into fully functional, ready-to-deploy units.

Our streamlined process covers kitting, assembly, testing, and packaging, ensuring seamless integration, strict quality control, and compliance with automotive, industrial, and medical standards. Fast turnaround and scalable solutions to meet low-to-high volume production needs.

✅ Full turnkey integration

✅ IPC-compliant quality testing & validation

✅ Scalable for low/high volume production

✅ One-stop kitting, assembly & packaging

Description

What is Box Build Assembly?

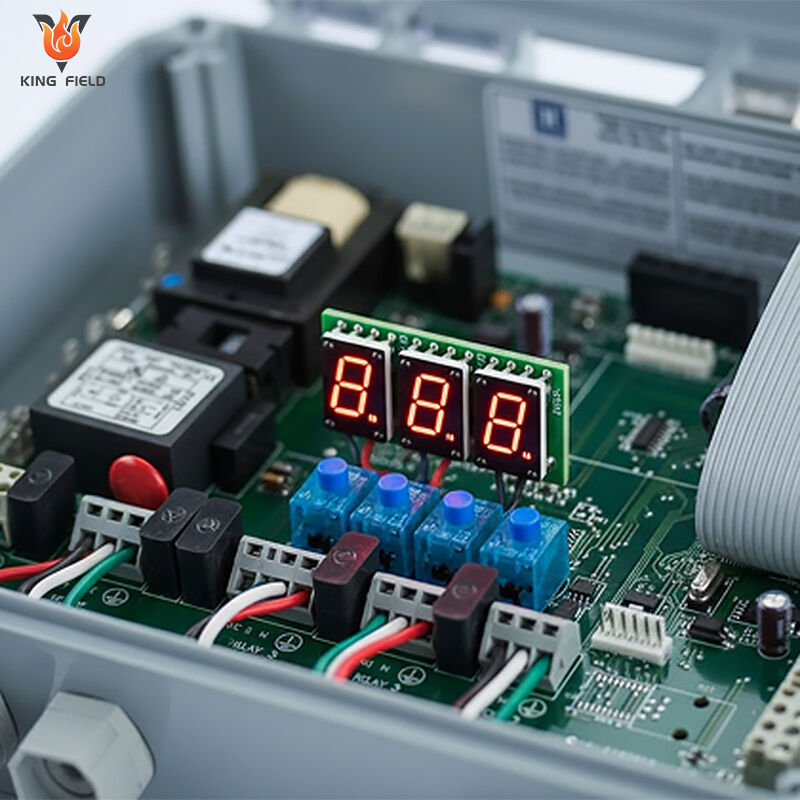

Box Build Assembly (also called systems integration) is the end-to-end process of integrating assembled PCBs, wiring, power supplies, user interfaces, enclosures, and firmware into a fully functional, ready-to-ship electronic product, going far beyond PCB assembly to deliver a complete “out-of-the-box” solution. It is a key turnkey service in electronics manufacturing, typically following PCB fabrication and assembly.

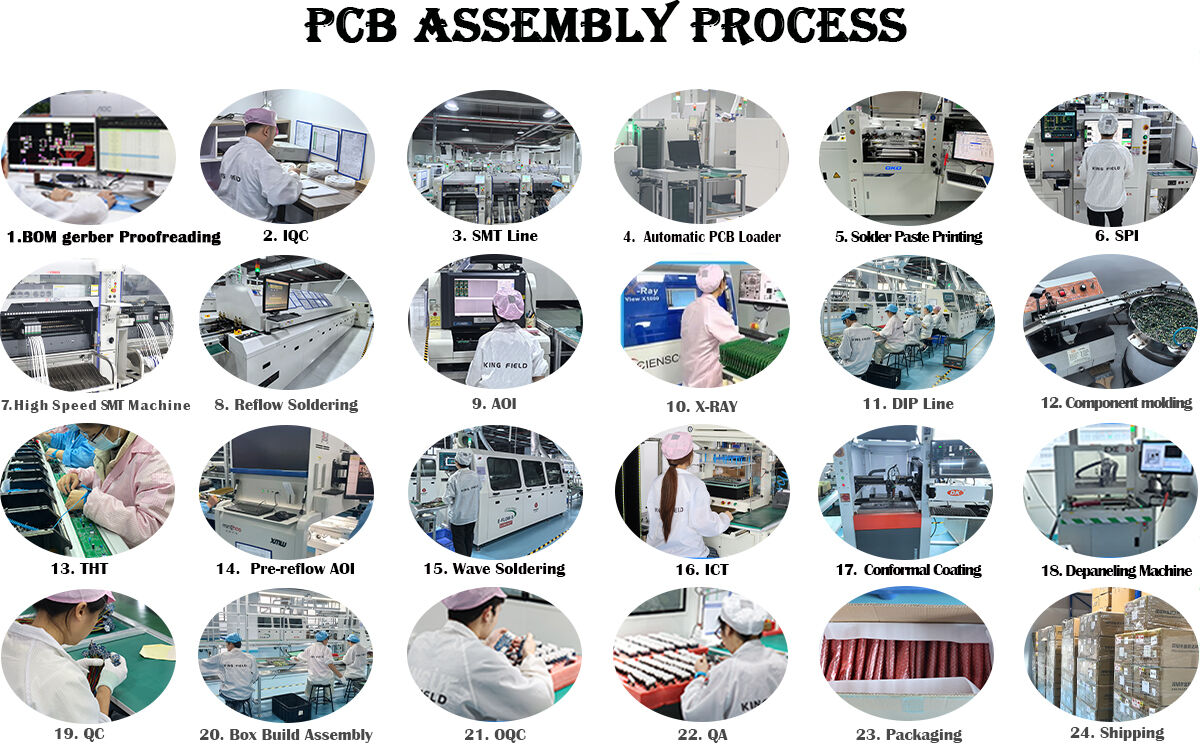

The Key Steps?

The Box Build Assembly process involves numerous steps, each crucial to the final product’s quality and functionality:

Design and DFM

Box-build assembly manufacturers can provide design inputs that will help optimize the final product. In this step, the manufacturer can collaborate with the customer for the tooling options, geometric considerations, and risk assessments. Design for manufacturing (DFM) is a critical evaluation tool to know if the design has the right tolerances, dimensioning, and materials that can be robustly manufactured.

Bill of Materials (BOM)

A comprehensive BOM is created, listing all necessary components and materials.

3D CAD Model

A 3D CAD model is developed to visualize the final product and identify potential issues before production.

Enclosure Preparation

The product’s enclosure is prepared, including any necessary modifications or customizations.

Material Sourcing and Procurement

All required materials and components are sourced and procured based on the BOM.

PCB manufacturing

The necessary PCBs are manufactured according to the design specifications.

Electronic Component Procurement

Electronic components are procured from reliable suppliers, ensuring quality and authenticity.

PCB Component Assembly

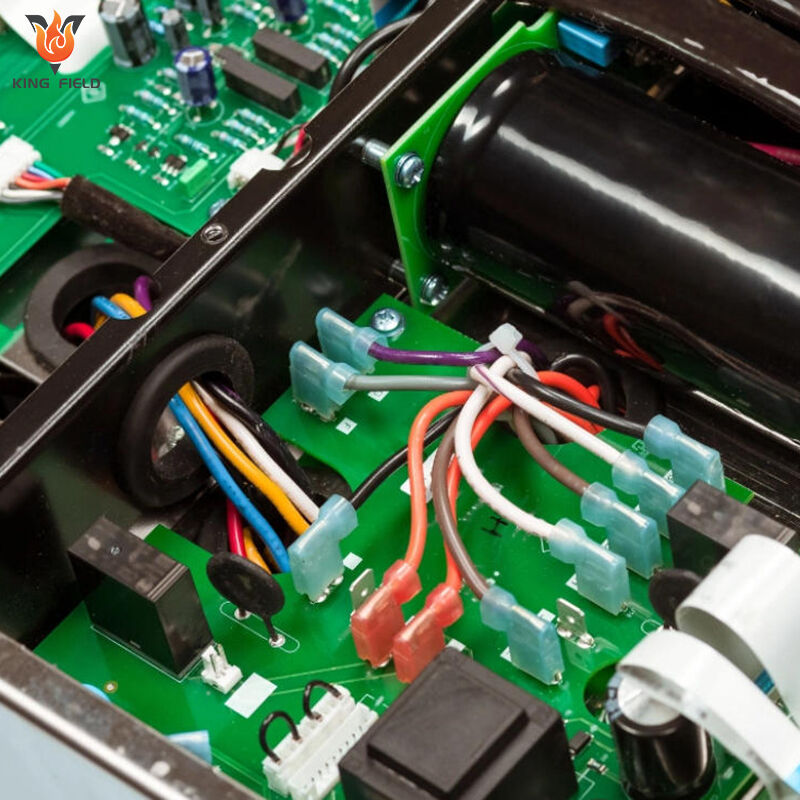

This step is where the PCB is placed inside the box or enclosure through picking, positioning, and inserting in precise locations. These movements can be done manually or automatically by robotic equipment to improve efficiency and accuracy. Industrial robots can be utilized through sensor technologies and vision systems to have higher capabilities in handling mechanical tasks.

Inspection and Testing

A critical quality verification step through product inspection and testing can be done by a box build assembly supplier. The required inspection can be done manually or automatically under specific magnification and proper lighting to spot defects and abnormalities. Testing, on the other hand, focuses on the functional and electrical performance of the box-build product. The test data sheet should be thoroughly discussed during the initial phase of the project to know the acceptable parameter ranges during testing. The acceptability criteria will also affect the test yield performance of the product.

The Advantages of Box Build PCB Assembly

Box Build PCB Assembly combines PCBA manufacturing, mechanical integration, firmware loading, and system testing into a single turnkey solution. For electronics brands and OEMs, this end-to-end service delivers tangible operational, cost, and quality benefits that fragmented production processes cannot match.

Streamlined Supply Chain & Reduced Coordination Burden

Eliminates the need to manage multiple vendors. A single EMS provider handles every step from component kitting to final packaging.

Reduces communication delays and misalignment risks between different teams. All integration decisions are centralized under one technical team.

Simplifies logistics with a single point of contact for order tracking, quality issues, and delivery updates.

Enhanced Product Quality & Reliability

System-level testing validates the performance of the entire integrated product, ensuring hardware-software-mechanical compatibility.

Strict compliance checks are embedded into the process, reducing the risk of non-compliant products reaching the market.

Standardized assembly workflows minimize human error, especially for complex products like industrial controllers or medical devices.

Cost Efficiency & Lower Total Cost of Ownership

Bulk component kitting and centralized production reduce material waste and purchasing costs.

Eliminates redundant testing steps that occur when multiple vendors each test their own components independently.

Cuts logistics costs by consolidating shipments into a single delivery of finished products, instead of shipping individual PCBs, enclosures, and accessories separately.

Scalability & Flexibility for Diverse Production Needs

Adapts seamlessly to small-batch prototyping, medium-volume production runs, and large-scale mass manufacturing.

Supports custom requirements without needing to switch vendors.

Enables easy design iterations during prototyping, as the same team can adjust both PCBA layouts and enclosure integration in tandem.

Applications of Box Build PCBA

· Industrial Automation & Control: PLCs, HMIs, motor drives, robotic controllers

· Medical Devices: Patient monitors, diagnostic equipment, infusion pumps, wearable health devices

· Telecommunications & Networking: 5G base station modules, routers/switches, fiber optic transceivers, IoT gateways

· Automotive Electronics: OBD modules, ADAS components, BMS, infotainment systems

· Aerospace & Defense: Avionics control units, military ruggedized computers, radar sensors

· Consumer Electronics & Smart Home: Smart hubs, wireless speakers, security cameras, smart thermostats

· Renewable Energy: Solar inverter controllers, energy storage management units, smart meters

· Test & Measurement Equipment: Oscilloscopes, data loggers, calibration tools

Why Choose Us?

Why Choose KING FIELD as Your China Box Build Assembly Manufacturer?

KING FIELD stands out as a trusted China-based box build assembly partner, delivering end-to-end solutions tailored to industrial, medical, automotive, telecom, and defense applications.

One‑Stop Turnkey Expertise

We handle full box build integration—from PCB assembly, custom wire harnesses, and enclosure fabrication to firmware loading, system‑level testing, and final packaging.

No need for multiple vendors: our team manages every step to ensure hardware‑software‑mechanical alignment and on‑time delivery.

Strict Quality & Regulatory Compliance

ISO 9001/13485 certified and compliant with IPC‑A‑610, MIL‑STD, ISO 16750, and FDA/CE standards.

In‑house testing labs (functional, environmental, EMI/RFI, shock/vibration) ensure zero‑defect output for mission‑critical devices.

Full traceability from component sourcing to final shipment, with detailed QC documentation for every batch.

Engineering & Customization Excellence

Our R&D team provides DFM/DFA feedback early in design, optimizing for cost, reliability, and scalability.

Rapid prototyping to low‑volume pre‑production to high‑volume manufacturing—flexible workflows adapt to your project stage.

Custom enclosures, EMI shielding, and thermal management solutions for harsh industrial, automotive, or aerospace environments.

Robust Supply Chain & Cost Efficiency

Strategic partnerships with global component distributors and local manufacturers ensure stable sourcing and competitive pricing.

JIT inventory and lean production minimize waste, reduce lead times, and lower total cost of ownership.

No hidden fees: transparent quoting with clear breakdowns for materials, labor, testing, and logistics.

Scalability & Fast Turnaround

Modular assembly lines enable quick changeovers for mixed‑volume orders (100–100,000+ units).

Quick‑turn prototyping (5–7 days) and mass production ramp‑up to meet tight market windows.

Dedicated project managers provide real‑time updates and resolve issues within 24 hours.

Post‑Delivery Support & Lifecycle Management

Comprehensive after‑sales service: repair, rework, component upgrades, and obsolescence management.

Long‑term partnerships with proactive lifecycle planning to extend product longevity and reduce replacement costs.

Production Capacity

| Assembly Types |

● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

||||

| Quality Inspection |

● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

||||

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB | ||||

| Component Types |

● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

||||

| Components Sourcing |

● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

||||

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste | ||||

| Order quantity |

● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

||||

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready | ||||