PCBA Prototyping

Rapid PCBA Prototyping for medical, industrial, automotive & consumer electronics. 24h fast turnaround, precision assembly, BOM matching, DFM analysis, and AOI/ICT testing—accelerate your R&D cycle. From small batches to functional prototypes, we ensure production-ready designs, reliable performance, and seamless scaling to mass production.

✅ 24h rapid prototyping

✅ SMT/BGA precision assembly

✅ DFM & full quality testing

✅ R&D to production scalability

Description

What is PCBA prototyping?

PCBA prototyping is a crucial test in the transition from product design to mass production. Kingfield Electronics, with over 20 years of industry experience, provides global clients with rapid prototyping, precise verification, and flexible iteration capabilities.

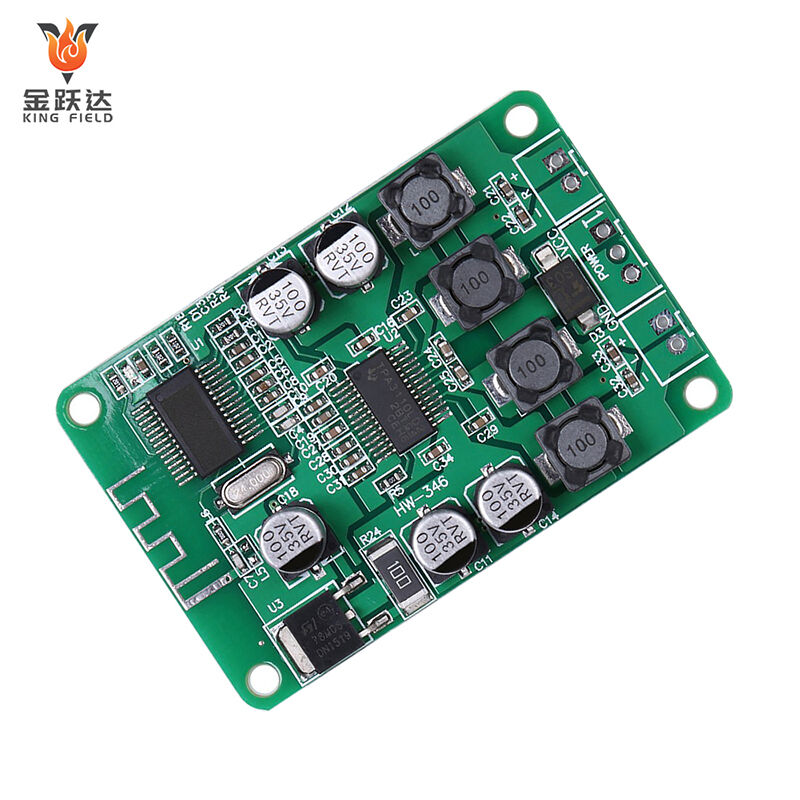

One-stop PCBA Prototyping Service

This helps companies proactively identify design flaws, optimize process solutions, reduce mass production risks, and accelerate product launch cycles. Prototype verification is an indispensable core step in the entire product development process, helping companies complete comprehensive testing and evaluation of design solutions before mass production begins. Kingfield provides one-stop prototyping solution.

It encompasses two key services: PCB bare board prototyping and PCBA prototyping

Our PCB bare board prototyping service focuses on verifying the functional effectiveness, layout rationality, and signal integrity of circuit designs to ensure full compliance with preset technical specifications. Through meticulous testing and analysis, we accurately pinpoint potential design flaws and provide optimization solutions, simultaneously improving product manufacturability and cost control efficiency.

Our PCBA prototyping and assembly service goes beyond the limitations of assembling individual components, emphasizing the functional synergy and performance compliance of the entire system. With precision assembly processes and comprehensive testing procedures, we help companies proactively identify and resolve various issues, effectively reducing project development costs and accelerating product launch cycles.

Excellent service

In the fiercely competitive PCBA industry, online PCB prototyping services have become the preferred choice for customers. While most service providers only offer standardized online quotes, Kingfield stands out with its deep customization capabilities, precisely adapting to the diverse project needs of different clients. Here are our core differentiating advantages:

• No minimum order quantity: Customer-centric, with a minimum order quantity of only 1 piece. Regardless of order size, we invest equal focus and professional resources to ensure consistent service quality.

• Flexible service customization: We offer a diverse range of value-added services, covering integrated circuit programming, bare PCB manufacturing, PCBA assembly, one-stop component procurement, design optimization/modification, etc., tailored to specific project needs.

• Comprehensive production coverage: Supports 1-56 layer multilayer PCB manufacturing, compatible with various materials such as FR4, Rogers, ceramic substrates, and high-frequency boards, easily meeting the technical requirements of different scenarios.

• Full-Scenario Assembly Capabilities: Covering the entire assembly process from SMT surface mount technology (SMT) to through-hole mounting, BGA soldering, lead-free hybrid assembly, wire harness assembly, and chassis integration, meeting the needs of complex projects.

• Multi-Dimensional Quality Inspection: Strictly controlling product reliability through multiple testing methods including flying probe testing, board-level/system-level testing, circuit bonding, and in-circuit testing, ensuring that prototype boards meet both functional and quality standards.

• Flexible Cooperation Models: Offering various cooperation models such as turnkey projects, semi-turnkey projects, and consignment services to adapt to the management and cost requirements of different projects, achieving win-win cooperation.

PCB bare board prototyping

Services include: rapid fabrication of 1-100 bare PCBs from Gerber files, supporting single/double-sided boards, multilayer boards (up to 24 layers), flexible boards, rigid-flex boards, and other types.

Core advantages:

• Fast Delivery: 24-hour expedited prototyping, regular orders delivered within 48-72 hours.

• Precise Reproduction: Minimum line width/spacing 3mil/3mil, minimum hole diameter 0.2mm, meeting high-density design requirements.

• Flexible Materials: Multiple substrates available, including FR-4, Rogers, and polyimide, suitable for various application scenarios.

• Verification Objectives: Ensuring circuit layout rationality, signal integrity, and structural adaptability, guaranteeing the bare board meets design specifications.

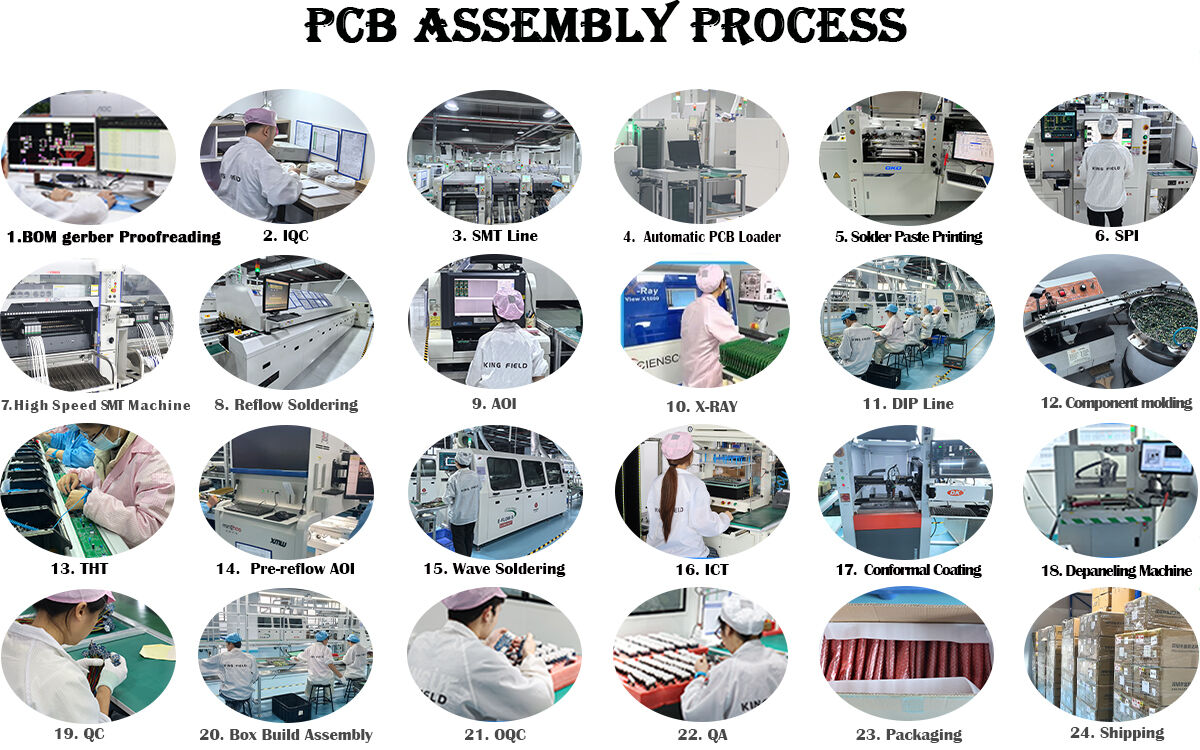

PCBA Prototype Assembly (SMT/DIP) Services offered: A full-process service including component procurement, SMT placement, DIP insertion, soldering, cleaning, and functional testing.

Core advantages:

• Component Supply: Global supply chain resources, supporting one-stop BOM procurement, and recommending alternative solutions for scarce components.

• Precision Assembly: Mounting accuracy ±0.03mm, supporting soldering of complex components such as 03015 ultra-small packages, BGA/CSP, etc.

• System Testing: Power supply testing, signal testing, and functional integrity testing, with detailed test reports provided.

• Verification Objectives: System functional synergy, component compatibility, process feasibility, and proactively addressing assembly potential issues.

Why choose KING FIELD?

The key reasons to choose Kingfield PCB prototype assembly quotes are "transparent and controllable pricing, excellent cost-effectiveness, and no hidden costs."

Our pricing system is designed around "helping to reduce R&D costs and adapting to small-batch needs," ensuring that every investment corresponds to clear value and avoiding the common industry trap of "low-price lead generation + hidden fees." Specific advantages are as follows:

1. Accurate and transparent pricing, with no hidden costs.

• Detailed breakdown: The quotation clearly lists all items including PCB bare board cost, component procurement fee, SMT/DIP assembly fee, testing fee, logistics fee, etc., with no ambiguous charges. Customers can verify each item.

• Free document review: After submitting the Gerber/BOM file, DFM analysis and quotation evaluation will be completed within 2 hours, without any document review or technical consultation fees.

• Price lock-in guarantee: The quotation is valid for 15 days after the solution is confirmed. During this period, minor fluctuations in raw material costs will not result in additional price increases, avoiding the risk of temporary price hikes.

2. Cost optimization enhances its cost-effectiveness, far surpassing competitors.

• Component Procurement Advantages: Leveraging global supply chain resources and long-term cooperative channels, component procurement prices are 5%-15% lower than market prices. Especially for scarce components, cost-effective alternatives can be provided, significantly reducing material costs.

• Cost Savings Through Process Optimization: Assembly processes are optimized in advance through DFM consulting, reducing unnecessary process losses and indirectly lowering production and time costs.

• Small Batch with No Premium: Supports small-batch prototype assembly of 1-500 pieces, with no minimum order quantity premium. Even for a single sample, you can enjoy bulk procurement and assembly pricing.

3. Pricing is deeply integrated with services, resulting in a higher return on investment.

• Free Value-Added Services Package: The quoted price includes full-process testing, detailed test reports, and after-sales technical support, all at no extra cost;

• Fast Delivery Saves Time and Costs: PCBA prototype assembly and delivery completed within 48 hours, accelerating product development iteration and market launch cycles, indirectly reducing project time costs;

• Seamless Mass Production Integration Saves Transition Costs: The prototype stage quote already includes space for mass production process adaptation, eliminating the need for readjusting the design and quote upon transitioning to mass production, achieving a smooth transition from "prototype quote → mass production quote" and avoiding redundant investment.

4. Flexible pricing to adapt to changing needs.

• Customized Pricing Solutions: We offer customized pricing for projects of varying industries and complexity, avoiding a "one-size-fits-all" approach.

• Iterative Procurement Discounts: For projects undergoing multiple iterations and prototyping, the assembly fee is discounted by 10% for the second iteration and beyond, reducing the cost of secondary prototyping after design optimization.

• Long-Term Partnership Rebates: Long-term partners enjoy annual sales rebates, priority production scheduling, and dedicated technical support, further enhancing our pricing advantages.

Manufacturing capacity

| Equipment manufacturing process capability | |||||

| SMT Capacity | 60,000,000 chips/day | ||||

| THT Capacity | 1.500,000 chips/day | ||||

| Delivery Time | Expedited 24 hours | ||||

| Types of PCBs Available for Assembly | Rigid boards, flexible boards, rigid-flex boards, aluminum boards | ||||

| PCB Specifications for Assembly | Maximum size: 480x510 mm; Minimum size: 50x100 mm | ||||

| Minimum Assembly Component | 01005 | ||||

| Minimum BGA | Rigid boards 0.3 mm; Flexible boards 0.4 mm | ||||

| Minimum Fine-Pitch Component | 0.2 mm | ||||

| Component Placement Accuracy | ±0.015 mm | ||||

| Maximum Component Height | 25 mm | ||||

Frequently Asked Questions

1. How long does it take to get a quote?

Within 2 hours (4 hours for complex projects), no review fee, quote valid for 15 days.

2. Is there a minimum order premium for small-batch prototypes?

No, enjoy low prices for 1-500 pieces, save 5%-15% on components, and get a 10% discount on iterative prototyping.

3. What is the fastest delivery time?

Standard 48 hours, expedited 24 hours for bare boards, 48 hours for assembly.

4. Which PCB types and packages are supported?

Covering single/double-sided boards, 24-layer multilayer boards, flexible boards, etc., supporting 03015/BGA packages.

5. How is quality guaranteed?

Are adjustments needed for mass production? ISO9001 + Level 3 quality inspection, yield rate ≥99.8%; seamless transition from prototype to mass production, no adjustments required.