First Article Inspection

Rigorous FAI services compliant with AS9102, IATF 16949 & ISO standards—validating dimensional accuracy, component placement, and assembly conformity for medical/industrial/automotive electronics before mass production.

Advanced tools (CMM, X-ray) detect defects early, minimizing risks and ensuring full design compliance. Fast report turnaround keeps your projects on track.

✅ Industry-standard compliant testing

✅ Precision verification via advanced equipment

✅ Early defect detection

✅ Fast, traceable FAI reports

Description

What is First Article Inspection?

First Article Inspection (FAI) is a critical quality validation process in PCB/PCBA manufacturing, used to verify that the first batch of products fully complies with design specifications, customer requirements, and industry standards. It serves as a "production gatekeeper" to catch design, process, or component mismatches early—before mass production begins, avoiding costly rework and delays.

FAI is mandatory for industries with strict quality regulations and is often required to comply with standards like AS9102 (aerospace) and IATF 16949 (automotive).

The Importance of First Article Inspection (FAI) in PCBA Manufacturing

FAI is a cornerstone of quality management in PCBA manufacturing, acting as a proactive quality gate that validates alignment between design, components, and production processes before mass production. Its importance extends beyond defect detection—it directly impacts cost control, compliance, customer trust, and product reliability, especially for high-precision, high-reliability PCBA applications.

Below are the core reasons FAI is indispensable for PCBA manufacturing:

Catches Costly Errors Early to Avoid Mass Production Wastage

The cost of fixing a defect escalates exponentially as a PCBA moves through the production lifecycle: a design flaw identified during prototyping costs a fraction of what it would cost to correct after thousands of units are manufactured.

FAI verifies that the first production unit matches approved CAD files, BOMs, and assembly drawings—catching issues like incorrect component polarity, misplaced pads, BOM mismatches, or solder joint defects before full-scale production.

It eliminates risks of scrapping entire batches, reworking hundreds of faulty PCBs, or delaying shipments—directly reducing manufacturing costs and minimizing material waste.

Validates Process Capability for Consistent Quality

FAI is not just about inspecting the product—it’s about validating that the production line can consistently deliver compliant products.

It confirms that key equipment is properly calibrated and programmed. For example, it checks if the pick-and-place machine places fine-pitch components within tolerance, or if the reflow profile produces solder joints that meet IPC-A-610 standards.

By establishing a golden sample, FAI sets a clear quality benchmark for all subsequent production runs, ensuring uniformity across batches and reducing variability in final products.

Ensures Compliance with Industry Regulations & Standards

For regulated industries, FAI is not optional—it is a mandatory requirement to meet global quality and safety standards:

· Aerospace & Defense: Complies with AS9102 standards, ensuring PCBA reliability for applications where failure can have catastrophic consequences.

· Automotive Electronics: Meets IATF 16949 requirements, validating PCBA performance for critical systems like ECUs, ADAS, and battery management systems that operate under extreme conditions.

· Medical Devices: Aligns with FDA and ISO 13485 standards, guaranteeing that PCBA used in diagnostic equipment or implantable devices meets strict safety and efficacy criteria.

FAI documentation also serves as critical evidence for customer audits and regulatory inspections, proving adherence to agreed-upon specifications.

Mitigates Supply Chain Risks from Component Substitutions

Component shortages, supplier changes, or part obsolescence are common in the electronics industry. FAI plays a key role in validating substitute components:

When replacing a discontinued IC or switching to a new component vendor, FAI verifies that the alternative part is fully compatible with the PCB design.

It prevents issues like component incompatibility, signal interference, or premature product failure caused by untested substitute parts.

Builds Customer Trust & Strengthens Partnerships

FAI provides transparent, traceable quality assurance that reassures customers their PCBA will meet or exceed expectations:

The detailed FAI report serves as a formal guarantee of product quality.

For custom PCBA projects, FAI allows customers to review and approve the first unit before mass production—aligning expectations and reducing the risk of post-delivery disputes.

Consistently delivering FAI-compliant PCBA positions manufacturers as reliable partners, especially for long-term contracts in high-reliability sectors.

Supports Continuous Process Improvement

FAI generates actionable data that drives manufacturing optimization:

Discrepancies identified during FAI highlight gaps in production processes or equipment calibration.

Engineering teams can use FAI data to refine SMT parameters, update AOI inspection thresholds, or adjust PCB design for better manufacturability—leading to higher yields and lower defect rates over time.

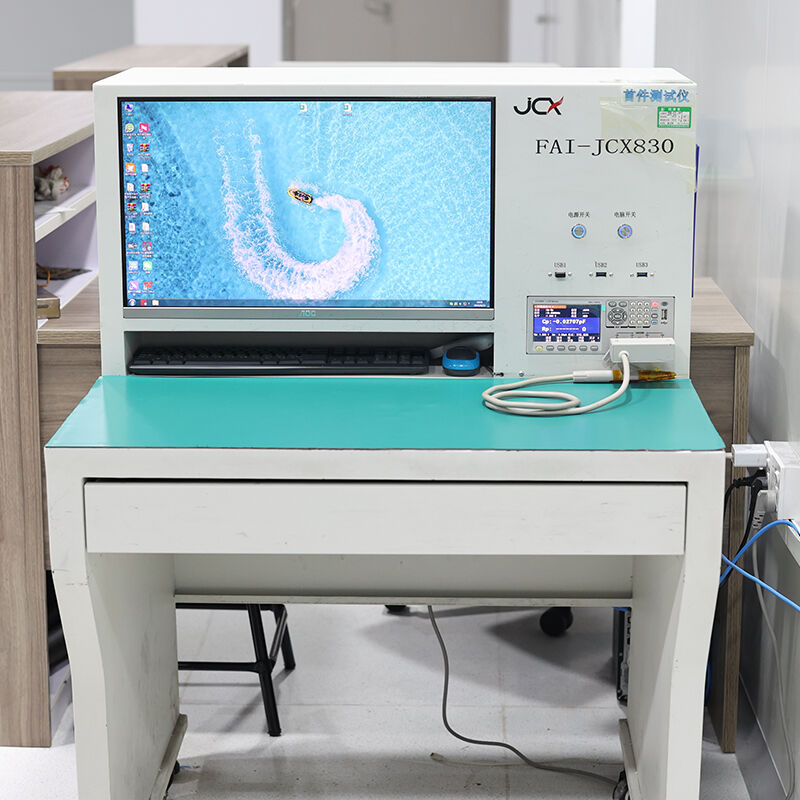

What is a First Article Inspection Instrument?

A First Article Inspection (FAI) instrument is a category of specialized testing and measurement equipment designed to execute the FAI process for PCB/PCBA manufacturing. These instruments are engineered to verify the compliance of the first production unit against design specifications, BOM requirements, and industry standards—covering physical, dimensional, and electrical checks with high precision and repeatability.

Unlike general-purpose tools, FAI instruments are tailored to the comprehensive validation needs of FAI, reducing human error and ensuring standardized, traceable inspection results. They range from standalone devices to integrated systems, depending on the complexity of the PCBA being inspected.

Difference Between FAI Instruments and General Testing Tools

| FAI Instruments | General Testing Tools | ||||

| Tailored for FAI’s comprehensive validation needs. | Designed for single-purpose checks. | ||||

| Generate standardized FAI reports for regulatory compliance. | Do not produce FAI-specific documentation; data needs manual compilation. | ||||

| Integrate with CAD/BOM data for automated comparison. | Require manual cross-checking against design files. | ||||

| Suitable for high-volume, high-reliability PCBA production. | Ideal for small-scale, manual inspection or spot checks. |

When do you need a First Article Inspection?

FAI is critical during a new product manufacturing process. Also, it helps to ensure if the manufacturing process can deliver products that comply with specifications. A first article inspection requirement need to assess one part with the unwritten assumption every part will follow the same production process.

Any alteration in the design or manufacturing process of the part violates this assumption. Therefore, there is a need for a first article inspection. Below is the list of conditions that needs a new first article:

A factory move

Manufacturing process change

New product introduction

Design change

You will need a new FAI for some changes. For instance, you will need a new FAI for any change from laser cutting to stamping. Also, a change to how parts are packages may not need a new first article inspection. FAI is an inspection equipment that helps to achieve a quality management system.