PCBA Testing

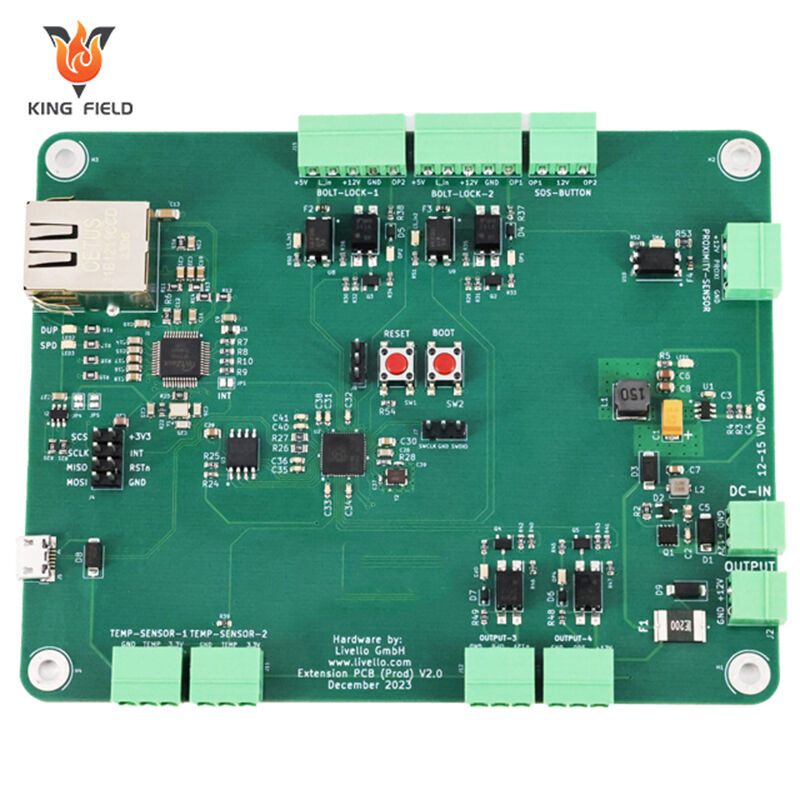

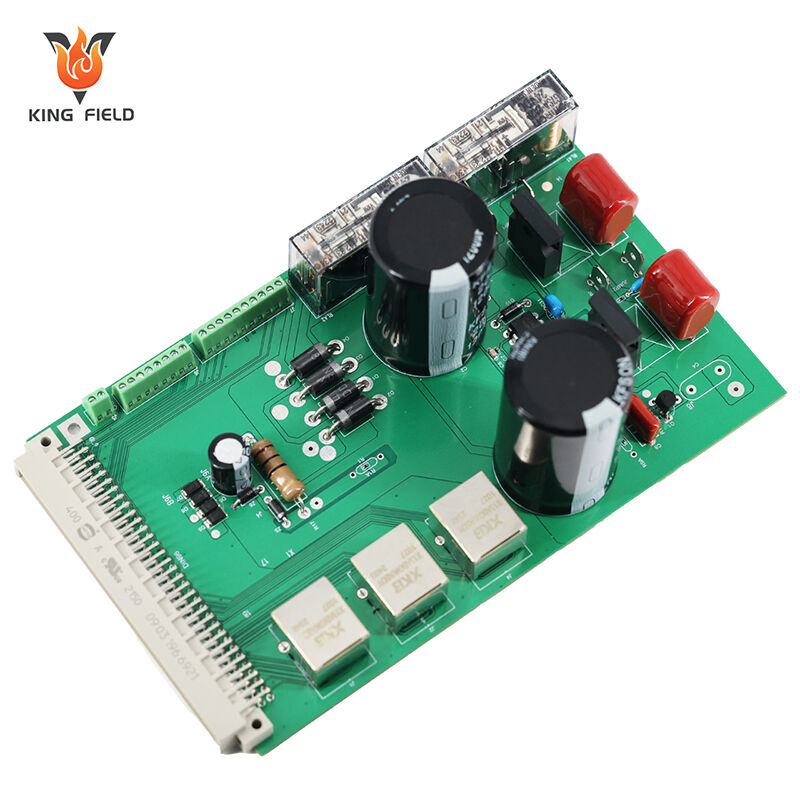

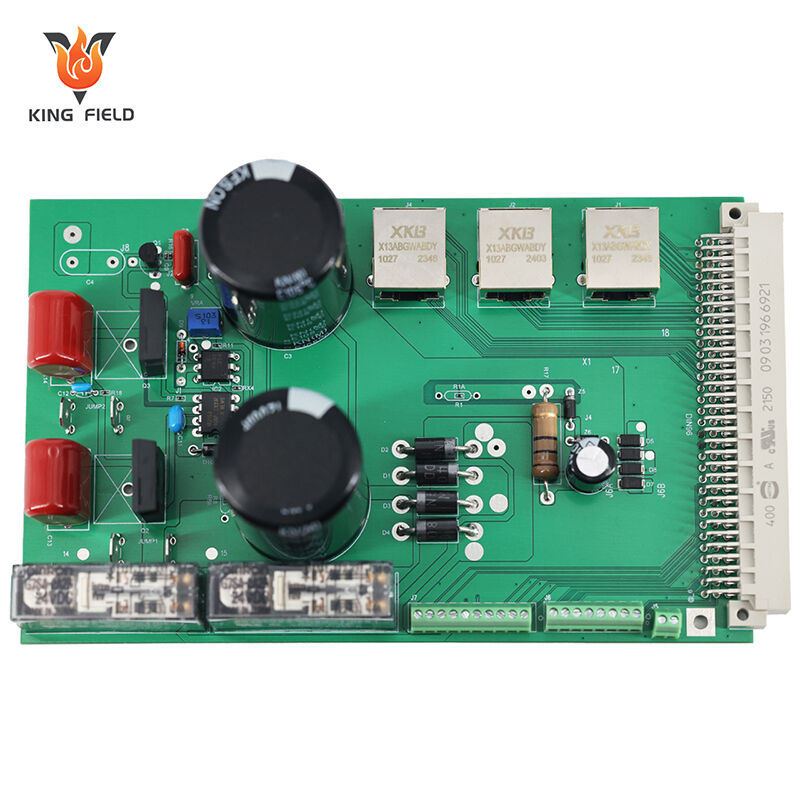

Comprehensive PCBA Testing services for medical, industrial, automotive & consumer electronics. From AOI and ICT to X-ray inspection and functional testing—we validate solder quality, component integrity, and performance. Ensure defect-free assemblies, compliance with industry standards, and reliable product launch.

Description

What is PCBA Testing?

PCBA testing refers to the functional, performance, and reliability testing of PCBA boards conducted using specialized equipment and processes after the PCB bare board manufacturing and component assembly are completed. It is a crucial step in identifying circuit defects and verifying product compliance, directly determining the quality of the PCBA prototype and the feasibility of subsequent mass production. To avoid inferior product quality, PCB functional testing is undoubtedly an indispensable step. It is no exaggeration to say that a company's brand reputation is closely related to its PCBAs. Therefore, it is not surprising that actual PCBA testing is considered the most important part of the production process.

Core testing objective

• Investigate manufacturing defects: such as cold solder joints, bridging, short circuits, open circuits, incorrect/missing components, etc.;

• Verify functional compliance: confirm that circuit signal transmission, power supply stability, interface compatibility, etc., meet design requirements;

• Ensure reliability: ensure stable product operation in real-world scenarios through environmental and aging tests;

• Reduce mass production risks: identify design or process issues early to avoid large-scale rework during mass production.

Common PCBA Test Types

• Basic Testing: Flying probe testing, AOI optical inspection;

• Functional Testing: Board-level testing, System-level testing;

• Professional Testing: In-circuit testing, Circuit bond testing;

• Specialized Testing: Lead-free process compliance testing, Environmental stability testing.

Kingfield Testing Service Advantages

Leveraging the aforementioned "multi-dimensional quality inspection" capabilities, our PCBA Testing not only covers all types of testing needs but also achieves a closed loop of "testing-feedback-optimization": through precise testing data, we provide customers with design optimization suggestions, simultaneously improving prototype reliability and manufacturability, and facilitating rapid mass production.

PCBA Test Types

PCB assembly technology is highly advanced, involving numerous crucial stages such as PCB production methods, component procurement and review, SMT assembly, DIP packaging, and printed circuit board assembly and testing. More specifically, PCB assembly and testing is the most critical internal control stage, directly determining the final product performance. PCBA testing requires selecting an appropriate solution based on the prototype stage, process complexity, and application scenario. Below are the core details of mainstream industry testing types, all of which are mature service modules from Kingfield:

I. Basic Inspection: Covering Core Defects in Manufacturing

1. Flying Needle Test

• Core Function: Accurately detects continuity and short circuit issues on bare or assembled PCBs without the need for specialized test fixtures.

• Technical Features: Testing accuracy ±0.03mm, supports 1-56 layer boards, testing speed 200 points/second, suitable for small-batch prototyping.

• Applicable Scenarios: Prototyping, small to medium-batch production, especially suitable for projects with frequent design iterations and where repeated fixture fabrication is unnecessary.

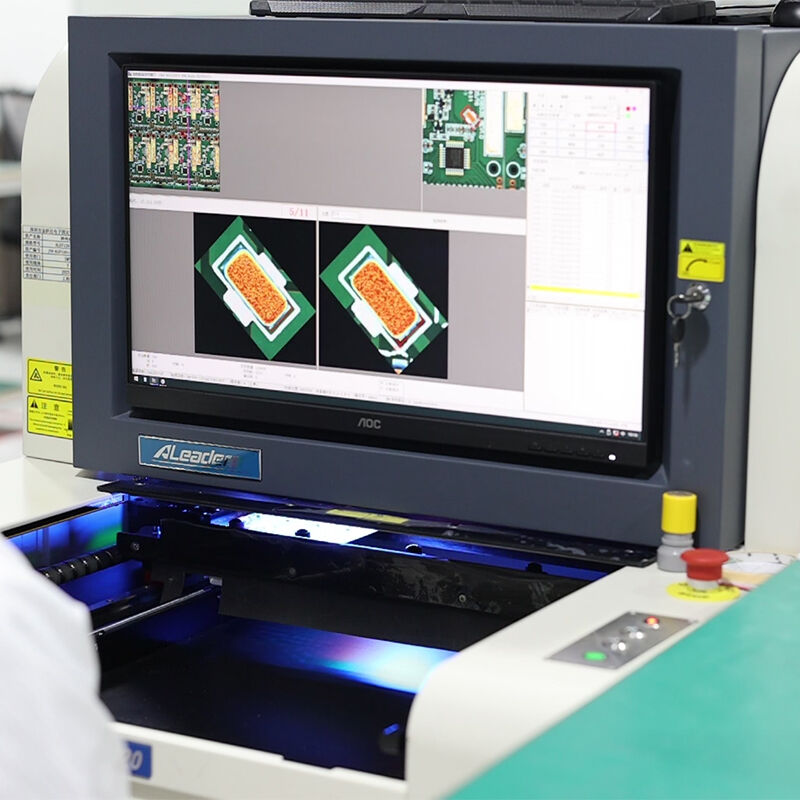

2. AOI Optical Inspection

• Core Function: Identifies solder joint appearance defects through machine vision, replacing manual visual inspection.

• Technical Features: 3D visual imaging, capable of detecting defects such as cold solder joints, bridging, insufficient solder, and misplaced/missing/reversed components.

• Applicable Scenarios: Full-process inspection after SMT placement, especially suitable for prototype boards with 03015 ultra-small packages and high-density placement.

3. ICT Testing ICT signals mainly include circuit switching, voltage and current values, fluctuation curves, amplitude, noise, etc.

II. Functional Testing: Verifying Core Design Requirements

1. Board-level testing

• Core Function: To test core functional modules of a PCBA board, such as power modules, signal modules, and interface modules.

• Technical Features: Customized test scripts simulate actual operating voltage/signal inputs and output module functionality compliance reports.

• Applicable Scenarios: To verify the design rationality of single functional modules, such as signal transmission modules of industrial control boards and power modules of medical equipment.

2. System-level testing

• Core Function: Integrating PCBA boards into a complete system to test overall functional synergy and performance stability.

• Technical Features: Simulating real-world application scenarios for continuous operation testing.

• Applicable Scenarios: Final verification of product prototypes to ensure they meet end-user requirements, such as the functionality of smart hardware and the linkage performance of industrial equipment.

Why is PCBA testing necessary?

PCBA testing is not an additional cost, but rather a "necessary line of defense" from product design prototype to mass production. Its core significance lies in four key dimensions, precisely echoing the various test types mentioned earlier:

1. Investigate manufacturing defects to avoid the risk of mass rework.

In PCBA production, even minor errors can lead to overall functional failure. Basic inspections such as flying probe testing and AOI optical inspection can 100% cover core defects such as conductivity, solder joint appearance, and component assembly, preventing these problems from flowing into subsequent stages—especially in the prototyping stage. Early detection can avoid large-scale rework due to design or process flaws during mass production, reducing losses by tens of times.

2. Verify the feasibility of the design and ensure that the functions meet the requirements.

The theoretical rationale behind design drawings needs to be verified through practical testing. Board-level and system-level testing can simulate real-world application scenarios to verify whether core functions such as power supply stability, signal transmission, and module collaboration meet design requirements. This accurately identifies issues where "the drawings are feasible but not practically usable," providing data support for design optimization and preventing products from being phased out by the market due to functional defects after launch.

3. Ensure reliability and durability, and enhance product reputation.

The long-term stable operation of PCBAs is a core competitive advantage of end products. Environmental stability testing and circuit bonding testing can verify the reliability of products under extreme temperature, humidity, and vibration conditions, ensuring continuous operation in complex scenarios such as industrial control, automotive electronics, and outdoor equipment. Simultaneously, ICT online testing detects the actual parameters of components, preventing shortened product lifespan due to latent component failures and maintaining brand reputation.

4. Meet industry compliance requirements and break down trade barriers.

For export-oriented products or special industries such as medical and automotive, there are clear compliance standards for PCBAs. Lead-free process compliance testing can issue authoritative reports to ensure that products meet international environmental standards; while circuit bonding testing and functional testing that comply with IPC-610 standards can meet industry access requirements, helping products to enter the global market smoothly and avoid being rejected due to compliance issues. In summary, PCBA testing is a "cost-controllable" venture investment. Whether in the prototype prototyping or mass production stage, investment in testing can bring several times the return—it can not only identify problems in advance and reduce rework costs, but also ensure product quality, accelerate the time to market, and broaden market access. Kingfield's full-type testing services ensure that every PCBA has mass production-level reliability and compliance through a closed loop of "precise testing + data feedback + optimization suggestions".

PCBA testing capability

The accuracy and efficiency of PCBA testing largely depend on the support of professional testing equipment. The following are the core equipment types that correspond to the testing value mentioned above; these are all mainstream equipment actually used by Kingfield in prototype testing, balancing accuracy, efficiency, and scenario adaptability:

Basic Defect Detection Equipment

1. Flying probe testing machine Core Functions: Detects PCB continuity, short circuits, and open circuits without requiring specialized fixtures.

Key Parameters: Testing accuracy ±0.03mm, testing speed 200 points/second, supports 1-56 layer boards, minimum hole diameter 0.2mm.

Equipment Advantages: Adaptable to small-batch prototypes; eliminates the need for repeated fixture fabrication during design iterations, reducing testing costs.

2. AOI System Core Functions: Machine vision identification of solder joint defects (cold solder joints, bridging, insufficient solder), and mis-assembly/missing/reverse component placement.

Key Parameters: 3D vision imaging, 10μm resolution, 1000mm²/second inspection speed, supports 03015 ultra-small packages.

Equipment Advantages: Replaces manual visual inspection, accuracy ≥99.7%, seamless integration with SMT production lines, without additional delivery time.

Functional Verification Equipment

1. Board-level functional testing system

Core Functions: Simulates real-world operating conditions to test the functionality of individual modules such as power supply modules, signal modules, and interface modules.

Key Parameters: Voltage test range 0-60V, current accuracy ±0.1mA, signal frequency support 0-1GHz. Equipment Advantages: Customizable test scripts enable rapid location of functional failure points, providing accurate data for design optimization.

2. System-level testing fixtures

Core Function: Build simulated application scenarios to test the overall functional synergy and stability of the integrated PCBA.

Key Parameters: Supports temperature (-40℃~125℃) and humidity (10%~95% RH) simulation, with continuous testing for up to 72 hours.

Equipment Advantages: Recreates the end-user environment, proactively identifies system-level compatibility issues, and avoids rework after product launch.

Reliability and Parameter Testing Equipment

1. ICT Online Tester Core Function: Detects actual component parameters, identifies cold solder joints, incorrect components, and component failures.

Key Parameters:

Number of test channels ≥ 1024, measurement accuracy ±0.01%, test speed ≤ 2 seconds/point.

Equipment Advantages: Requires customized fixtures, suitable for medium-batch testing, traceable parameter data, ensuring component accuracy.

2. Environmental Test Chamber Core Function: Simulates extreme environments, tests PCBA reliability under high and low temperatures, humidity, and vibration.

Key Parameters:

Temperature range -40℃~150℃, humidity range 5%~98% RH, vibration frequency 5~500Hz.

Equipment Advantages: Verifies long-term stable operation of products, adaptable to complex scenarios such as industrial control and automotive electronics.

Compliance Testing Equipment

1. XRF Fluorescence Spectrometer Core Function: Detects lead content in solder joints, verifying RoHS compliance.

Key Parameters:

Detection range: Na-U;

Detection limit: ≤1ppm;

Testing time: ≤3 minutes/board.

Equipment Advantages: Non-destructive testing, rapid generation of authoritative compliance reports, breaking down international trade barriers.

2. Circuit Bond Strength Tester Core Function: Tests the bond strength and signal transmission stability of high-frequency/precision PCBs.

Key Parameters:

Pull force testing range: 0-50g;

Accuracy: ±0.1g;

Signal testing frequency: up to 60GHz.

Equipment Advantages: Complies with IPC-610 standard, ensuring product reliability in high-frequency and precision applications.

FAQ

Q1. What if incomplete documentation or unclear test objectives lead to inaccurate testing?

A: Submit complete documentation as required. Customized testing requires supplementary operating parameters. Kingfield offers free pre-review services; our technical team can recommend suitable equipment based on core objectives to avoid resource waste or omissions of critical items.

Q2. How to resolve insufficient test accuracy or data distortion due to improper equipment selection or incorrect parameter settings?

A: Select equipment based on PCB complexity (3D AOI for high-density boards, flying probe testing for small-batch prototypes). If unsure, consult Kingfield engineers. Strictly adhere to equipment parameter thresholds, with settings controlled by an original manufacturer-certified operator throughout to avoid PCB damage or data loss due to over-range testing.

Q3. What to do if the test report shows "suspected defect," or the test passes but the function fails during actual use?

A: Kingfield provides defect classification and interpretation services, marking defect impacts according to application scenarios and providing rectification suggestions. If a defect is found to be "laboratory qualified but actually failed," system-level testing can be supplemented. We will build a customized environment to simulate actual working conditions and complete end-to-end verification.

Q4. High-frequency/precision PCB testing is affected by signal interference, and lead-free PCBs must meet RoHS compliance. How can this be ensured?

A: High-frequency/precision boards are tested in a shielded laboratory using dedicated 60GHz high-frequency equipment. Engineers optimize test points to reduce signal attenuation. Lead-free PCBs are tested using an XRF fluorescence spectrometer (lead content ≤0.1%), and an internationally recognized RoHS compliance report is issued, supporting third-party authoritative certification.

Q5. Small-batch prototype testing is costly, and test records are easily lost and untraceable. What are the solutions?

A: Choose a fixture-free testing solution. Kingfield has no minimum order premium for small-batch testing and supports on-demand combination of test items to control costs. After testing, cloud report storage services are provided, fully archiving test data, defect screenshots, and optimization solutions for easy follow-up iterations and traceability.