PCB Surface Finish Types

Premium PCB Surface Finishes for medical/industrial/automotive/consumer electronics—tailored to enhance solderability, corrosion resistance, and long-term

reliability. Choose from industry-leading options to match your application’s environmental and performance needs.

✅ HASL

✅ ENIG

✅ OSP

✅ Immersion Silver/Tin

Description

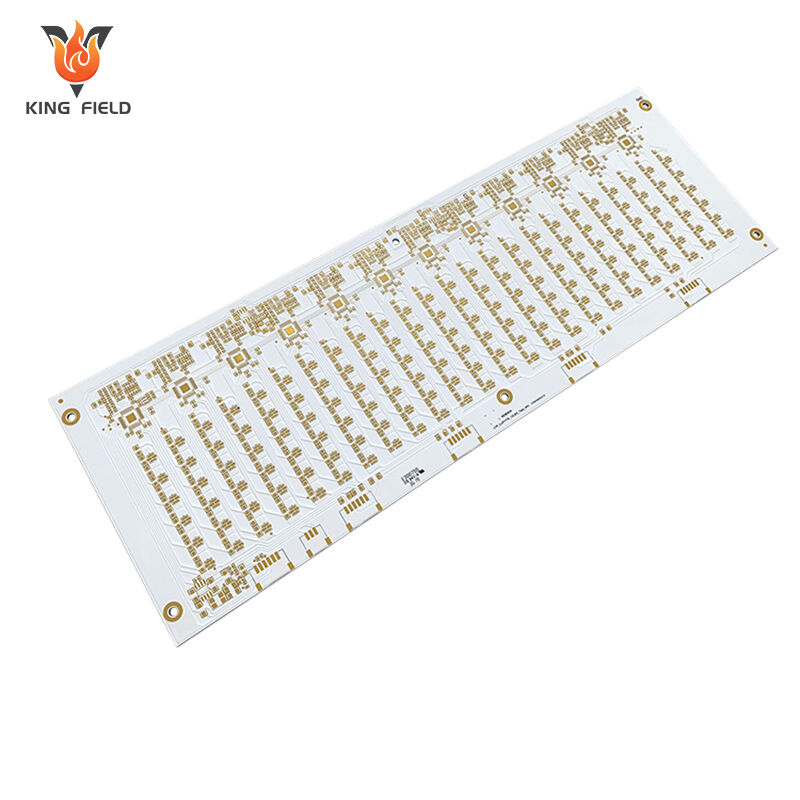

PCB Surface Finish Types

PCB surface finishes protect copper pads from oxidation, enhance solderability, and ensure reliable component connections. Below are common types, key traits, and industry applications (aligned with medical, industrial, automotive, consumer electronics):

HASL (Hot Air Solder Leveling)

· Process: Molten solder coating + hot air leveling for uniform thickness.

· Key Traits: Low cost, good solderability; uneven surface (not ideal for fine pitches).

· Applications: Consumer electronics (low-cost appliances), industrial control (non-precision PCBs).

ENIG (Electroless Nickel Immersion Gold)

· Structure: Nickel layer (barrier) + thin gold layer (protection/solderability).

· Key Traits: Flat surface, excellent corrosion resistance, compatible with fine pitches/BGA; higher cost.

· Applications: Medical devices (ISO 13485 compliance), automotive ECUs, high-density PCBs (BGA/QFP).

Immersion Silver

· Process: Thin silver layer deposited on copper.

· Key Traits: Low cost, flat surface, good solderability; prone to tarnishing (needs storage care).

· Applications: Consumer electronics (smartphones/laptops), industrial sensors.

Immersion Tin

· Process: Tin layer coating, no nickel barrier.

· Key Traits: Flat surface, compatible with lead-free soldering; risk of tin whiskers (long-term reliability).

· Applications: Low-volume industrial equipment, legacy PCBs.

OSP

· Process: Thin organic film coating copper.

· Key Traits: Ultra-low cost, flat surface, lead-free compatible; limited rework cycles, sensitive to · moisture.

· Applications: Consumer electronics (mass production), automotive low-power components.

ENEPIG

· Structure: Ni-Pd-Au layers for enhanced barrier protection.

· Key Traits: Superior corrosion resistance, high reliability, compatible with harsh environments; premium cost.

· Applications: Aerospace/defense, automotive underhood components, medical implants.

Hard Gold

· Process: Thick electroplated gold layer (wear resistance).

· Key Traits: Excellent for high-wear applications (connectors/contacts); expensive, not for soldering.

· Applications: Industrial connectors, automotive battery terminals, medical device contacts.

Core Comparison Table

| Finish Type | Cost | Solderability | Best For | ||

| HASL | Low | Good | Low-cost, non-fine pitch PCBs | ||

| ENIG | High | Excellent | High-density, medical/automotive PCBs | ||

| OSP | Ultra-low | Good | Mass-produced consumer electronics | ||

| ENEPIG | Premium | Excellent | Harsh-environment, high-reliability PCBs | ||

Production Capacity

| Assembly Types |

● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

||||

| Quality Inspection |

● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

||||

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB | ||||

| Component Types |

● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

||||

| Components Sourcing |

● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

||||

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste | ||||

| Order quantity |

● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

||||

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready | ||||