BGA Assembly

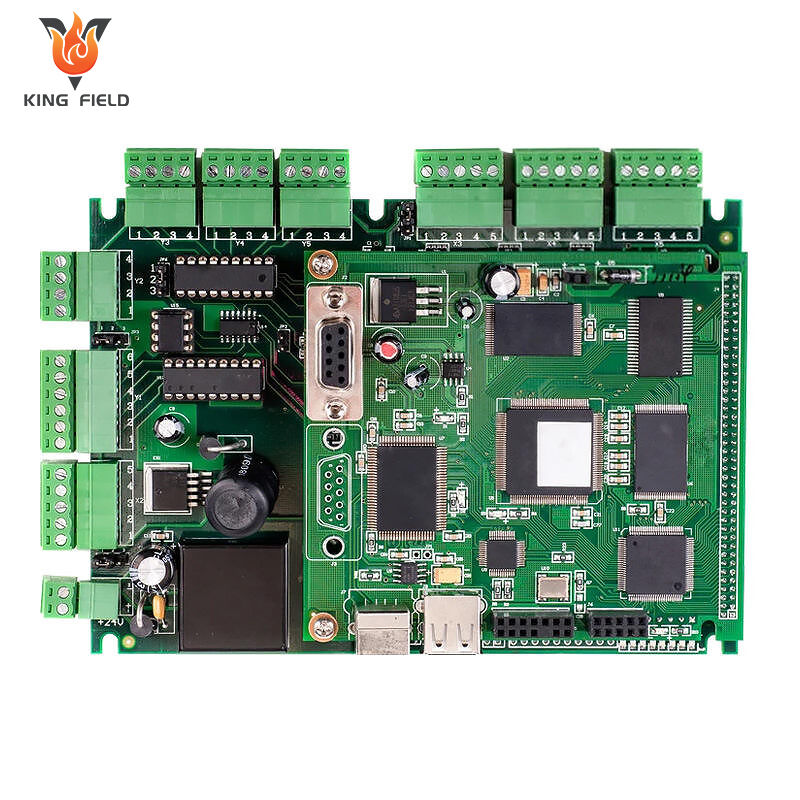

Precision BGA Assembly for high-density, high-performance electronics (medical/industrial/automotive/consumer). Expert reflow soldering, X-ray inspection, and DFM optimization—paired with 24h prototyping, fast delivery, and strict quality control. Ensure reliable connections, signal integrity, and compatibility for complex BGA packages.

✅ X-ray inspection for solder quality

✅ 24h prototyping | fast turnaround

✅ DFM support & high-precision placement

✅ Multi-industry complex electronics focus

Description

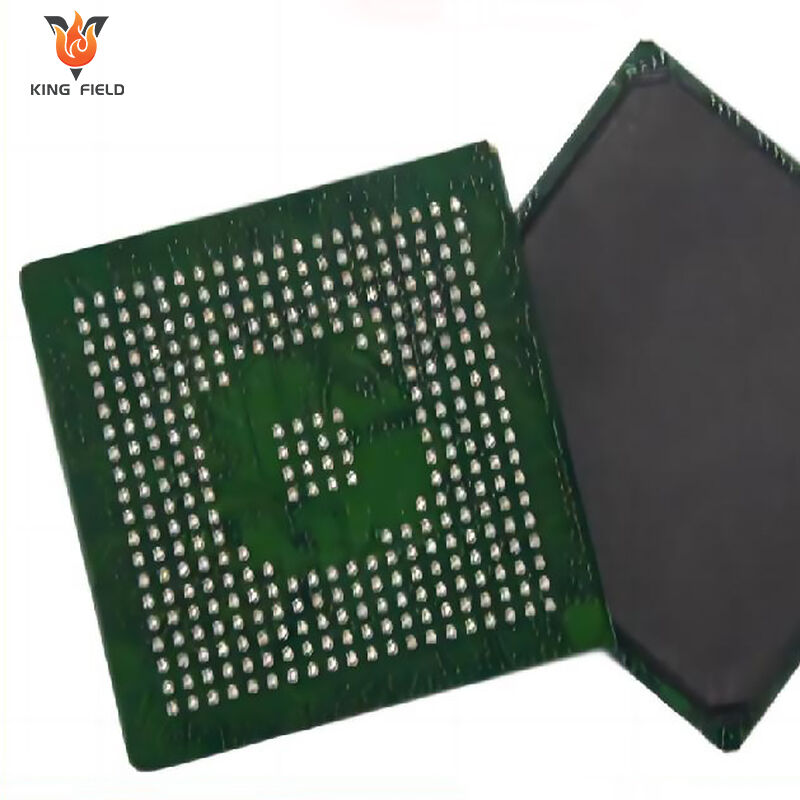

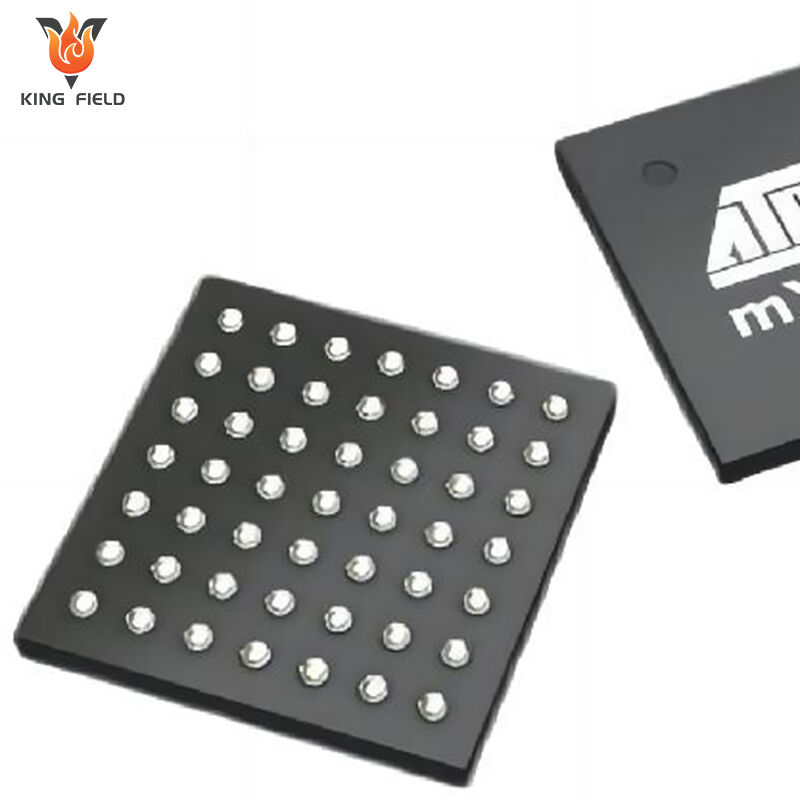

BGA assembly is a PCB assembly process for integrated circuit chips (such as CPUs and FPGAs) with an array of spherical solder balls on the bottom. The core process involves soldering the chip to the corresponding pad area on the PCB through solder paste printing, precise component placement, reflow soldering, and X-ray inspection to achieve electrical connection and mechanical fixation. This technology allows for the placement of more I/O interfaces within a limited space, adapting to high-density integration requirements. It offers advantages such as good heat dissipation, stable signal transmission, and strong vibration resistance. However, it requires high precision in placement and precise control of the soldering temperature profile, and necessitates specialized testing equipment. It is widely used in high-end electronic products such as smartphones, computers, and servers, and is a key assembly technology for achieving high-density, high-performance circuit integration.

Advantages

BGA assembly, with its unique structural design and manufacturing process characteristics, possesses several significant advantages in the field of electronics manufacturing, as follows:

- High-Density Integration Capability:

BGA replaces traditional pins with a bottom-arrayed solder ball design, allowing for more I/O interfaces within a limited chip package area. This caters to the high pin count requirements of high-end chips (such as CPUs and FPGAs), meeting the trend towards miniaturization and high-density integration in electronic products.

- More Stable Electrical Performance:

Short, thick solder balls shorten the signal transmission path, reducing signal attenuation and delay, while also mitigating crosstalk risks and ensuring the integrity of high-speed signal transmission. This is particularly suitable for the signal requirements of high-performance devices such as 5G and artificial intelligence.

- Excellent Heat Dissipation:

The larger contact area between the bottom of the BGA-packaged chip and the PCB, combined with the solder ball array, aids in heat conduction. Combined with heat sinks and other structures, it quickly dissipates the heat generated during chip operation, improving the long-term stability of the device.

- High Mechanical Reliability:

The solder balls provide cushioning, better resisting external mechanical influences such as vibration and impact. Compared to traditional pin-based packages, this reduces pin breakage and detachment caused by external forces, extending product lifespan.

- Excellent adaptability to soldering processes:

The solder ball array is evenly distributed, resulting in more uniform heating during reflow soldering and reducing the soldering defect rate. Furthermore, the resulting structure exhibits strong structural stability, meeting the demands of mass production in industrial settings and improving production efficiency.

Equipment parameters

| Equipment manufacturing process capability | |

| SMT Capacity | 60,000,000 chips/day |

| THT Capacity | 1.500,000 chips/day |

| Delivery Time | Expedited 24 hours |

| Types of PCBs Available for Assembly | Rigid boards, flexible boards, rigid-flex boards, aluminum boards |

| PCB Specifications for Assembly |

Maximum size: 480x510 mm; Minimum size: 50x100 mm |

| Minimum Assembly Component | 01005 |

| Minimum BGA | Rigid boards 0.3 mm; Flexible boards 0.4 mm |

| Minimum Fine-Pitch Component | 0.2 mm |

| Component Placement Accuracy | ±0.015 mm |

| Maximum Component Height | 25 mm |