BGA Assembly Capabilities

Precision BGA Assembly for high-reliability electronics (medical/industrial/automotive/telecom). Advanced X-ray alignment, reflow soldering, and void-free joint technology ensure stable performance for BGA, QFN, CSP & micro-BGA components.

✅ X-ray guided placement

✅ Void-free soldering

✅ Micro-BGA/QFN/CSP component support

Description

BGA Assembly Capabilities

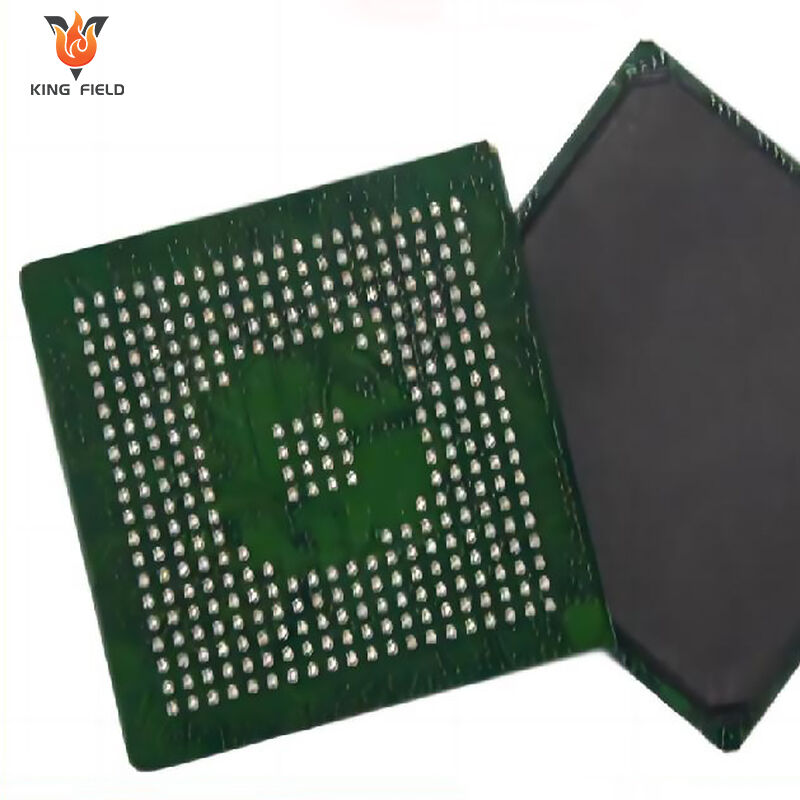

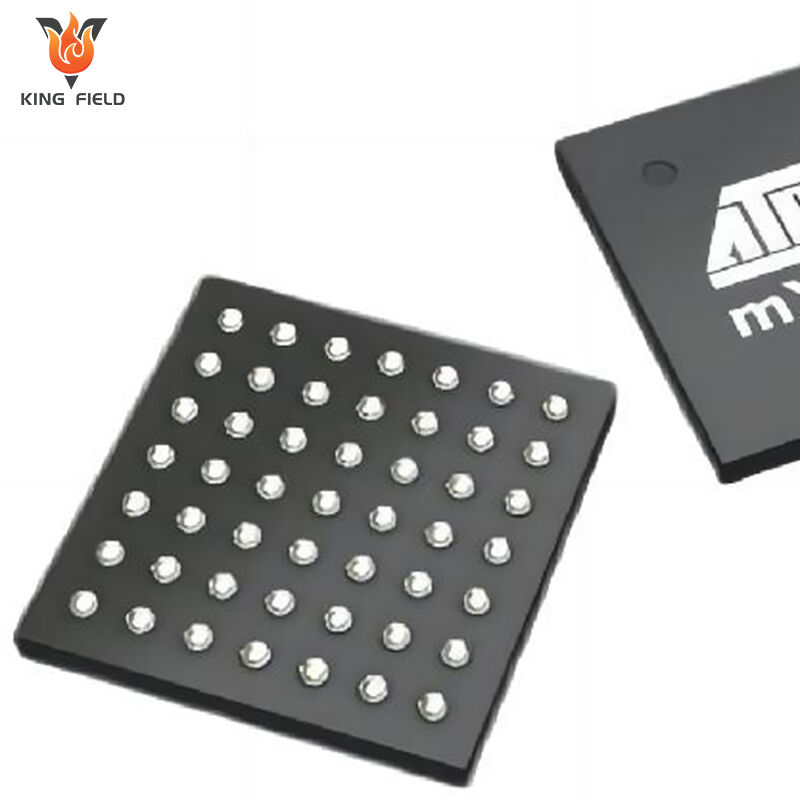

BGA Assembly Capabilities refer to the comprehensive technical expertise and production capacity of an SMT factory in handling BGA (Ball Grid Array) packages – high-density packaged chips with solder ball arrays on the bottom – covering aspects such as placement, soldering, inspection, process control, and reliability assurance. It is a core indicator determining the yield, electrical performance, and long-term reliability of high-pin-count/high-frequency chip assembly, and a key evaluation criterion when choosing a BGA assembly service provider.

Core Features:

· High Component Density: Solder balls are arranged in a grid, supporting hundreds/thousands of connections in a small footprint.

· Superior Thermal & Electrical Performance: Short solder ball connections reduce signal delay/EMI and improve heat dissipation.

· Mechanical Reliability: Solder balls absorb vibration/shock.

Key Assembly Process:

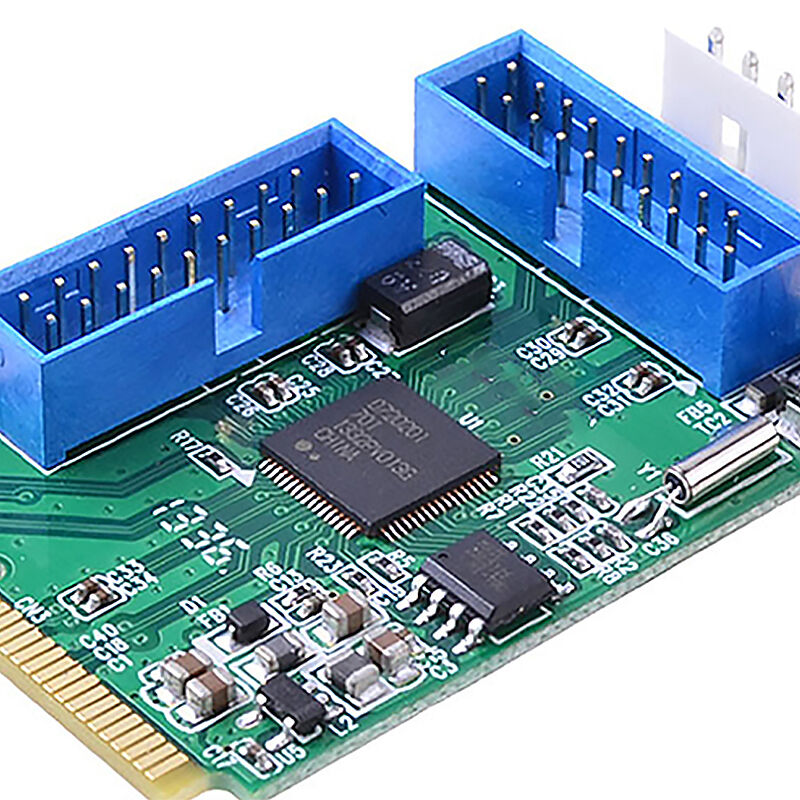

· Stencil Printing: Solder paste deposition on PCB BGA pads.

· Placement: Precision alignment of BGA chip on PCB.

· Reflow Soldering: Controlled heating to melt solder balls, forming reliable joints.

· Inspection: X-ray testing to detect defects; AOI for outer alignment.

· Rework: Specialized equipment for BGA removal/replacement if defects are found.

Industry Applications:

· Medical: MRI/CT scanner processors, wearable device microcontrollers (ISO 13485 compliant).

· Industrial Control: PLC main chips, robotic control modules (high-temperature resistance).

· Automotive: ADAS processors, EV battery management system (BMS) ICs (vibration-resistant).

· Consumer Electronics: Smartphone/ laptop CPUs, IoT device chips (high-density design).

Advantages:

Enables miniaturization of high-performance electronics.

Better heat management than traditional packages.

Resistant to environmental stress.

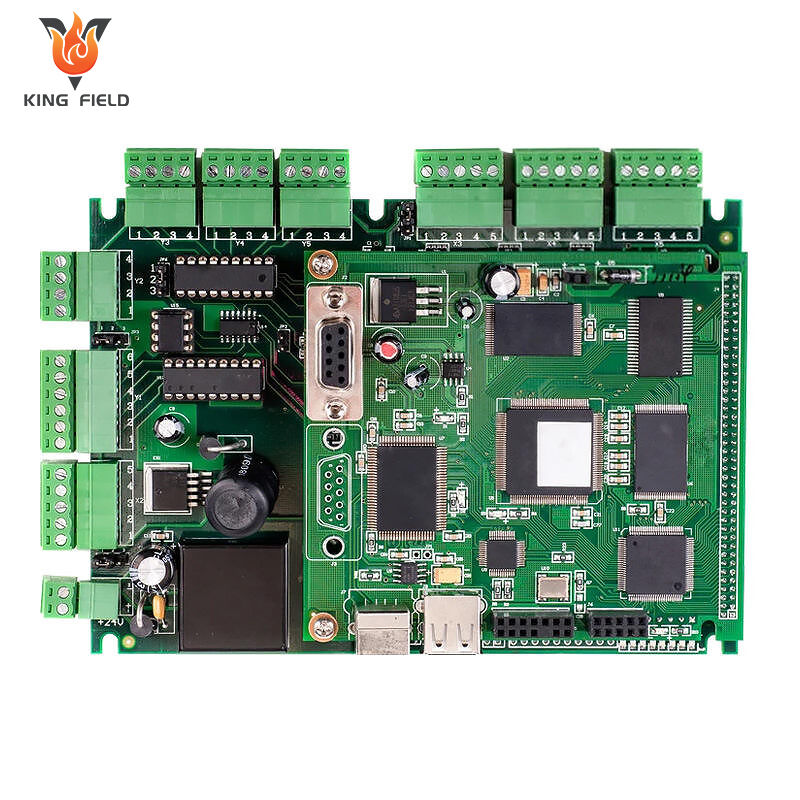

KING FIELD has strong and comprehensive capabilities in BGA assembly, covering multiple aspects such as diverse packaging support, high - precision mounting, professional testing and rework, and adaptation to multi - field mass production. The specific capabilities are as follows:

Diverse BGA Package Compatibility

KING FIELD supports diverse BGA package types (µBGA, vfBGA, CSP, WLCSP, LGA), handling ultra-fine 0.2mm pitch BGAs with over 1000 balls to meet high-density, high-pin-count chip assembly needs for premium electronics.

High - Precision and High - Efficiency Mounting

KING FIELD deploys high-speed SMT lines (Yamaha YSM20R/YS24) with ±0.04mm placement accuracy. Boasting robust capacity, it meets

small-batch and mass production needs, plus double-sided BGA assembly for higher PCB integration.

Comprehensive Quality Testing System

KING FIELD has full professional testing equipment: X-ray testers detect hidden BGA solder defects (cold joints, voids), paired with AOI, 3D-SPI, ICT for multi-stage testing (solder paste to finished product), ensuring BGA assembly quality.

Professional Rework Capabilities

KING FIELD has dedicated BGA rework stations for professional removal/replacement of defective BGAs, reducing production losses and ensuring stable delivery quality.

Adaptability to Multi - Field Professional Scenarios

KING FIELD holds IATF 16949/ISO 13485 certifications, delivering BGA assemblies that meet strict industry requirements. With rich experience in high-end projector/medical motherboard BGA assembly, its solutions serve industrial control, automotive electronics, smart home, and withstand vibration/high temperatures.

One - Stop Supporting Services

KING FIELD offers one-stop PCB/PCBA services: BGA assembly plus component sourcing, DFMA design optimization, etc. We partner with global premium suppliers, simplifying customers’ supply chains and boosting project efficiency.

Production Capacity

| Assembly Types |

● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

||||

| Quality Inspection |

● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

||||

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB | ||||

| Component Types |

● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

||||

| Components Sourcing |

● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

||||

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste | ||||

| Order quantity |

● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

||||

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready | ||||