High Volume Assembly Service

High-efficiency high-volume PCBA assembly for automotive, industrial, and consumer electronics—delivering consistent quality, fast turnaround, and cost optimization for mass production runs.

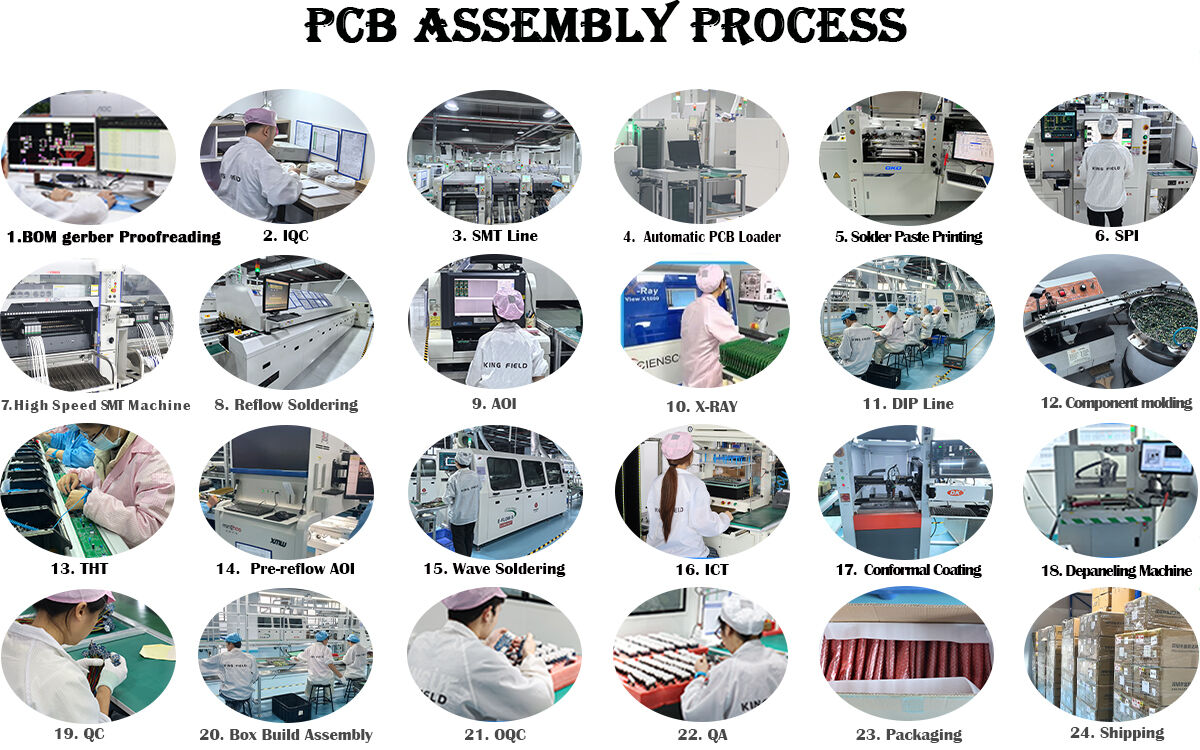

Our automated SMT lines, strict IPC-compliant quality checks, and scalable workflows ensure on-time delivery even for large orders. From prototyping ramp-up to full-scale manufacturing, we meet your high-volume demands without compromising precision.

✅ Automated SMT lines for fast mass production

✅ IPC-compliant quality control & traceability

✅ Cost-optimized solutions for large orders

✅ Seamless ramp-up from prototyping to volume

Description

In PCB assembly, the requirements differ in volume. When you are producing a product on a large scale, you require high volume PCB assembly services to achieve your goals. Basically, projects of 1000+ pieces are categorized as high-volume PCBA services and need a reliable and reputable assembly partner, like KING FIELD, to handle them.

BENEFITS OF HIGH VOLUME PCB ASSEMBLY

The core value of high-volume PCB assembly lies in achieving stable quality, controllable costs, and efficient delivery through large-scale, automated production, meeting the needs of large-scale market deployment of mature products. Its advantages are mainly reflected in the following five aspects:

Significant Cost Advantages, Lowering Unit Production Costs

· Raw Material Procurement Discounts: Large-volume component purchases allow for long-term agreements with suppliers, securing lower unit prices and significantly reducing core material costs.

· Fixed Cost Amortization: Fixed costs such as production line and equipment depreciation, and factory rent, can be spread across a high volume of products, reducing the proportion of fixed costs per unit.

· Improved Production Efficiency and Cost Reduction: Fully automated production lines operate continuously and stably, reducing time lost due to line changes and manual operations, increasing output per unit of time, and lowering labor and energy costs per product.

Highly Consistent Product Quality and Stability

· Automated Processes Reduce Human Error: From solder paste printing, component placement, reflow soldering to testing, the entire process is completed by high-precision equipment, avoiding the randomness of manual operation and ensuring that the welding accuracy and component placement consistency of each PCB meet industry standards.

· Standardized Testing System Guarantees Yield: Equipped with online AOI and X-Ray testing equipment, 100% automated testing is performed on large volumes of products, promptly identifying and removing defective products; simultaneously, statistical process control monitors production parameters, providing early warnings of quality fluctuations and stabilizing product yield.

· Standardized Production Process Parameters: For established products, optimal production parameters are locked in, avoiding quality fluctuations caused by frequent adjustments, making it suitable for fields with high reliability requirements such as medical and automotive industries.

Efficient Delivery Capabilities to Meet Large-Scale Market Demand

· Fully Automated Production Lines for High-Volume Output: High-speed pick-and-place machines can assemble tens of thousands or even hundreds of thousands of components per hour. Combined with a continuous production process, this allows for rapid response to orders of hundreds of thousands or even millions of units, shortening the overall delivery cycle.

· Flexible Supply Chain Collaboration: Large-scale production is typically supported by a comprehensive supply chain system, enabling Just-In-Time supply of raw materials. This reduces inventory buildup while ensuring production continuity and preventing delivery delays due to material shortages.

Comprehensive Quality Traceability and Compliance Assurance

· Full-Process Traceability Management: Using barcode or QR code technology, information such as production batch, raw material batch, test data, and operator is recorded for each PCB. This allows for quick identification of the root cause of any quality issues, reducing recall costs.

· Compliance with Industry Certification Requirements: Large-scale production lines are typically built according to standards such as ISO 9001, IATF 16949, and ISO 13485, meeting the compliance requirements of different industries and facilitating smooth market entry for products.

Advantages of Long-Term Supply Chain and Technical Support

· For long-term, stable, high-volume orders, manufacturers are more willing to invest resources in process optimization, further improving product reliability and production efficiency.

· Establishing long-term strategic partnerships with manufacturers provides access to value-added services such as priority scheduling, technical upgrade support, and cost optimization suggestions, enhancing product competitiveness in the market.

The core differences between small-batch/prototype PCBA production.

| High-volume PCB assembly | Small-batch / Prototype PCBA | ||||

| Order Volume | Batch sizes of tens of thousands of units or more | Batch sizes from a few pieces to several thousand pieces | |||

| Production Method | Fully automated production lines, continuous operation | Primarily semi-automatic or manual assembly, with frequent line changes | |||

| Cost Control | Focus on minimizing unit cost | Prioritizing delivery speed and flexibility | |||

| Design Adaptability | Suitable for standardized products; high cost of changes | Suitable for products in the R&D phase, supporting rapid design iterations | |||

| Testing Method | Primarily online automated testing, supplemented by sample testing | Manual + semi-automatic testing, primarily 100% inspection | |||

Why choose Kingfield's High Volume Assembly Service?

Kingfield’s High Volume PCB Assembly Service delivers automated, scalable, cost-optimized PCBA for mass-market products, with end-to-end turnkey support, strict quality control, and competitive pricing for mature designs.

Turnkey One-Stop Execution

· Full process: component sourcing, PCB fabrication, SMT/THT assembly, reflow/wave soldering, box build, and functional testing.

Supports high-mix mass production with flexible line configuration for fast changeovers.

Highly Automated Production Line

· Key equipment: automatic solder paste printers, high-speed pick-and-place machines, reflow ovens, wave soldering systems, online AOI, and X-Ray inspection.

Lean manufacturing with fixed process parameters to minimize human error and ensure consistency.

Strict Quality Assurance

· Compliance: IPC-A-610, ISO 9001, IATF 16949, ISO 13485, RoHS, and REACH.

· Full-process control: SPC for parameter monitoring, 100% automated inspection, random sampling, and traceability via barcode/QR code for batches and materials.

Supply Chain & Cost Optimization

Bulk component purchasing with long-term supplier agreements for lower unit costs.

JIT material supply to reduce inventory and ensure production continuity.

Fixed cost amortization via high-volume continuous operation to lower per-unit overhead.

Industry Expertise

Deep experience in industrial control, automotive electronics, medical devices, consumer electronics, and health & wellness products.

Technical support for DFM optimization to improve yield and reduce production costs

Production Capacity

| Assembly Types |

● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

||||

| Quality Inspection |

● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

||||

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB | ||||

| Component Types |

● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

||||

| Components Sourcing |

● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

||||

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste | ||||

| Order quantity |

● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

||||

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready | ||||