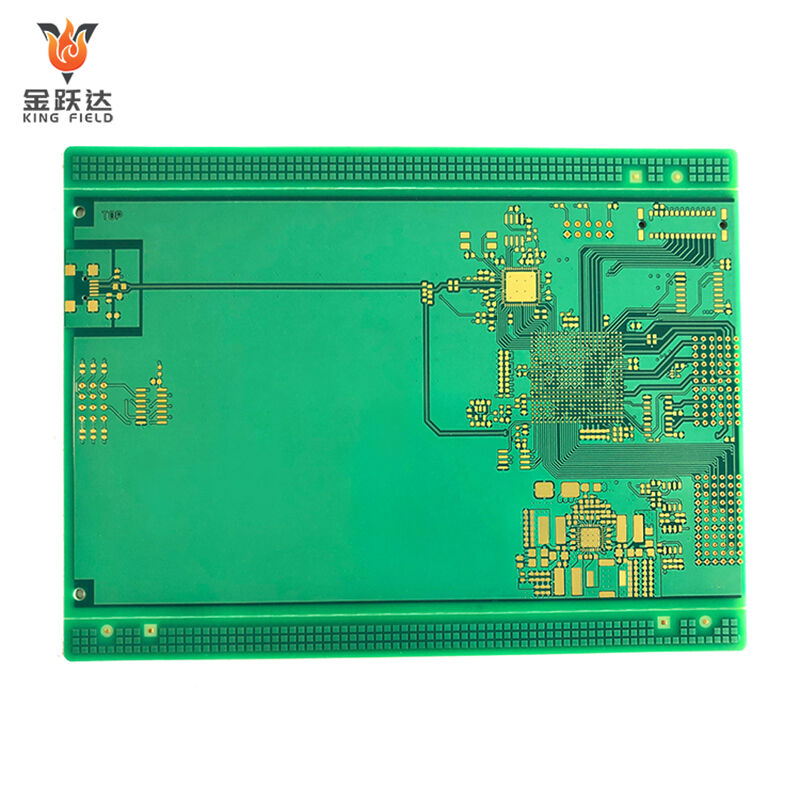

Automotive PCB

Automotive-Grade PCBs engineered for reliability in harsh vehicle environments (temperature extremes, vibration, EMI). Compliant with IATF 16949, AEC-Q200 standards—ideal for infotainment, ADAS, powertrain, and EV/hybrid systems.

Premium materials, precise circuitry, and multi-stage testing (AOI/ICT/X-ray) ensure long-term performance. 24h prototyping, fast delivery, and DFM optimization support seamless integration into automotive electronics.

✅ IATF 16949/AEC-Q200 compliant

✅ Harsh environment resistance (temp/vibration/EMI)

✅ EV/ADAS/powertrain/infotainment focus

Description

What are Automotive PCBs?

Automotive PCBs are printed circuit boards specifically designed and manufactured for automotive electronic systems. They are the core hardware carriers for various automotive electronic devices and must meet the stringent working

environment and safety standards of automobiles. Unlike ordinary PCBs used in consumer electronics, their core characteristics are high reliability, high weather resistance, and strong electromagnetic compatibility.

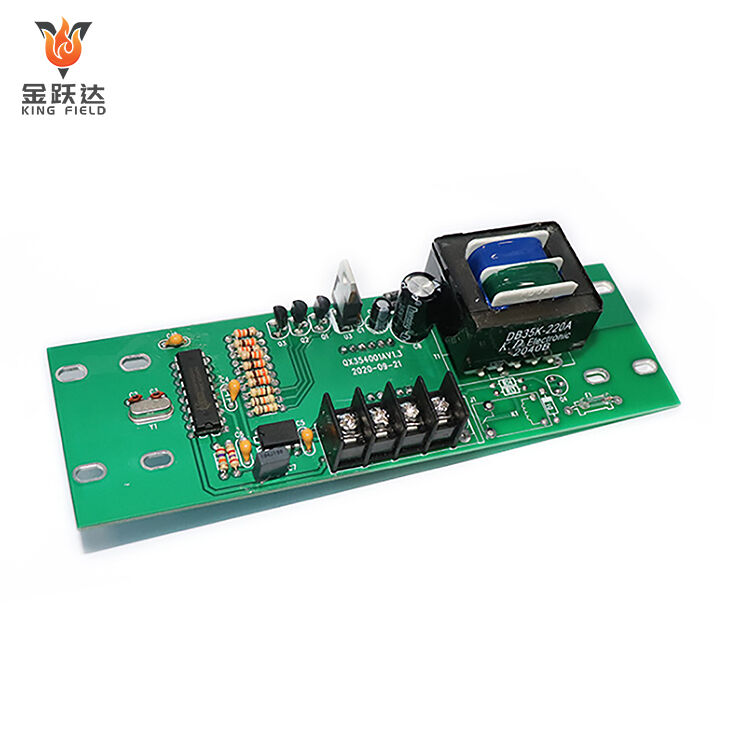

Core positioning and application scenarios

Car pcb cover all electronic systems in a vehicle and can be categorized by function as follows: Powertrain Control System: Engine Control Unit (ECU), Transmission Control Board, Battery Management System (BMS) PCB,

Motor Drive Board; Body Control System: Body Control Module (BCM), Door Control Board, Air Conditioning Control Board, Lighting Control Board; Safety System: Airbag Control Board, Anti-lock Braking System (ABS) PCB,

Electronic Stability Program (ESP) PCB, Autonomous Driving Sensors PCB; In-vehicle Entertainment and Intelligent System: Central Control Screen Mainboard, In-vehicle Navigation PCB, Vehicle Networking Module PCB, Smart Cockpit

Control Board; Auxiliary System: Tire Pressure Monitoring System (TPMS) PCB, Reversing Camera Control Board, Charging Pile Internal PCB .

Key technical requirements

Extreme environmental tolerance

· Temperature range: Must withstand a wide operating temperature range of -40℃ to 125℃, far exceeding that of consumer electronics PCBs (0℃ to 70℃);

· Vibration and shock resistance: Must meet the requirements of continuous vibration and collision impact during vehicle operation, and solder joints and circuits must be protected against detachment and breakage;

· Moisture and corrosion resistance: Water absorption rate <0.1%, able to withstand the high temperature, high humidity, and oily environment of the engine compartment, preventing circuit oxidation or short circuits.

High reliability and security

· Flame retardancy rating: Must meet UL94 V-0 rating, and some key modules must meet even stricter flame retardancy standards;

· Electrical stability: Insulation resistance ≥10¹²Ω, withstand voltage ≥2500V, to prevent short circuits and leakage from causing vehicle malfunctions or safety accidents;

· Lifespan requirements: Design lifespan ≥15 years or 200,000 kilometers, much longer than consumer electronics PCBs (3~5 years).

Strong electromagnetic compatibility (EMC)

The interior of a car is densely packed with electronic systems, resulting in severe electromagnetic interference. Automotive PCBs must meet the following requirements:

· Electromagnetic radiation suppression (EMI): to prevent their own electromagnetic signals from interfering with other modules;

· Electromagnetic interference immunity (EMS): to resist interference from external electromagnetic signals and ensure stable control signals.

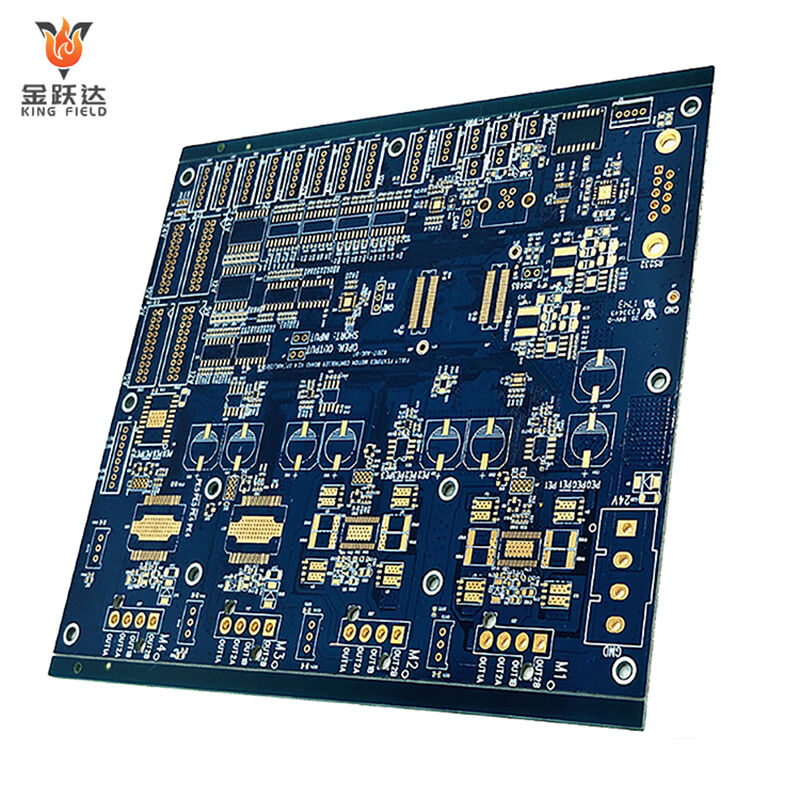

Special process adaptation

· Thick copper design: Powertrain PCBs often use copper thicknesses of 3oz or more to meet the requirements of high current transmission;

· High-frequency substrate: Autonomous driving radar PCBs require high-frequency substrates such as Rogers to reduce signal loss;

· Lead-free process: Compliant with environmental standards such as RoHS and ELV, and some high-end models need to meet even stricter halogen-free requirements.

Mainstream types and base materials

| Car pcb Type | Substrate selection | Applicable Scenarios | Core Requirements | ||

| Conventional control PCB | High Tg FR-4 (Tg≥170℃) | Body control and entertainment system | Temperature resistant and vibration resistant | ||

| Powertrain PCB | Aluminum-based PCB, Copper-based PCB | Engine ECU, motor drive board | High thermal conductivity, high current carrying capacity | ||

| High-frequency/radar PCB | Rogers substrates, ceramic PCBs | Vehicle radar, 5G vehicle networking module | Low dielectric loss and stable high-frequency signal | ||

| Flexible/Rigid-Flexible PCB | Polyimide (PI) substrate | irregularly shaped installation parts such as car doors and seats | Bend-resistant and suitable for small spaces | ||

Industry Standards and Certification

Automotive circuit boards must pass stringent automotive industry certifications, including:

IATF 16949: an automotive industry quality management system standard covering the entire design and production process;

AEC-Q200: a passive component reliability testing standard (PCBs must meet the temperature cycling, vibration, and damp heat tests);

and OEM certifications: such as Volkswagen VW 80000 and Toyota TS16949, which are exclusive standards of car manufacturers and require in-house audits before supply can commence.

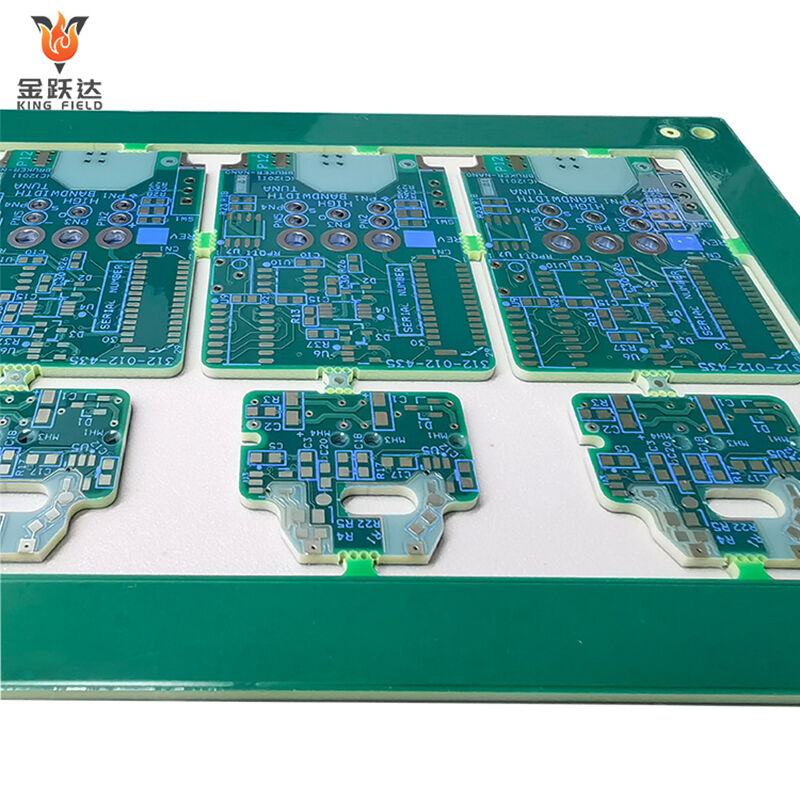

Rigid RPCB Manufacturing Capability

| Item | RPCB | HDI | |||

| minimum linewidth/linespacing | 3MIL/3MIL(0.075mm) | 2MIL/2MIL(0.05MM) | |||

| minimum hole diameter | 6MIL(0.15MM) | 6MIL(0.15MM) | |||

| minimum solder resist opening (single-side) | 1.5MIL(0.0375MM) | 1.2MIL(0.03MM) | |||

| minimum solder resist bridge | 3MIL(0.075MM) | 2.2MIL(0.055MM) | |||

| maximum aspect Ratio (thickness/hole diameter) | 0.417361111 | 0.334027778 | |||

| impedance control accuracy | +/-8% | +/-8% | |||

| finished thickness | 0.3-3.2MM | 0.2-3.2MM | |||

| maximum board size | 630MM*620MM | 620MM*544MM | |||

| maximum finished copper thickness | 6OZ(210UM) | 2OZ(70UM) | |||

| minimum board thickness | 6MIL(0.15MM) | 3MIL(0.076MM) | |||

| maximum layer | 14 layer | 12 layer | |||

| Surface treatment | HASL-LF、OSP 、Immersion Gold、 Immersion Tin 、Immersion Ag | Immersion Gold、OSP、selectiveimmersion gold、 | |||

| carbon print | |||||

| Min/max laser hole size | / | 3MIL / 9.8MIL | |||

| laser hole size tolerance | / | 0.1 |