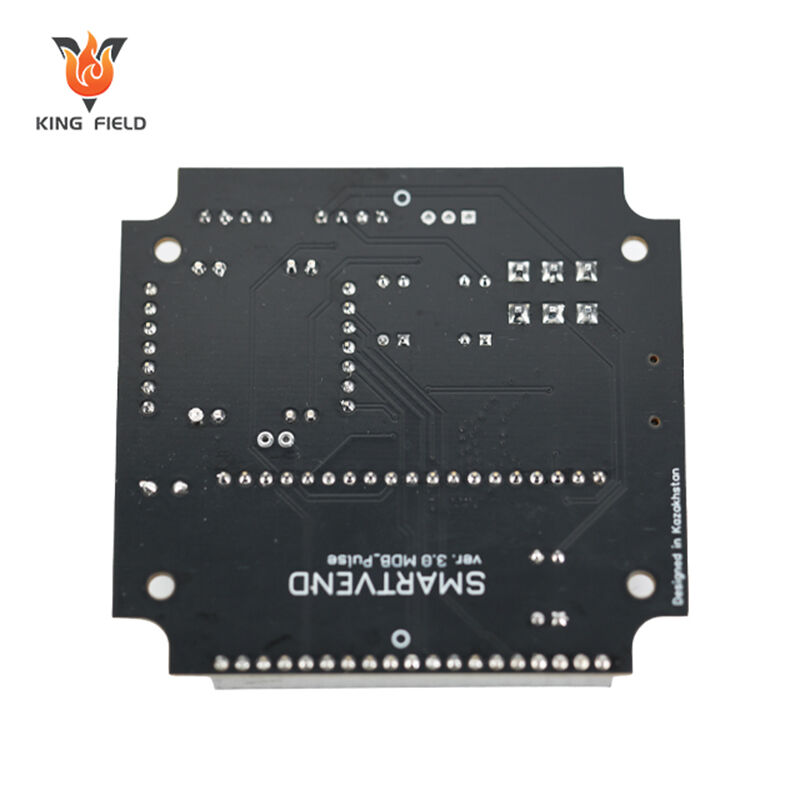

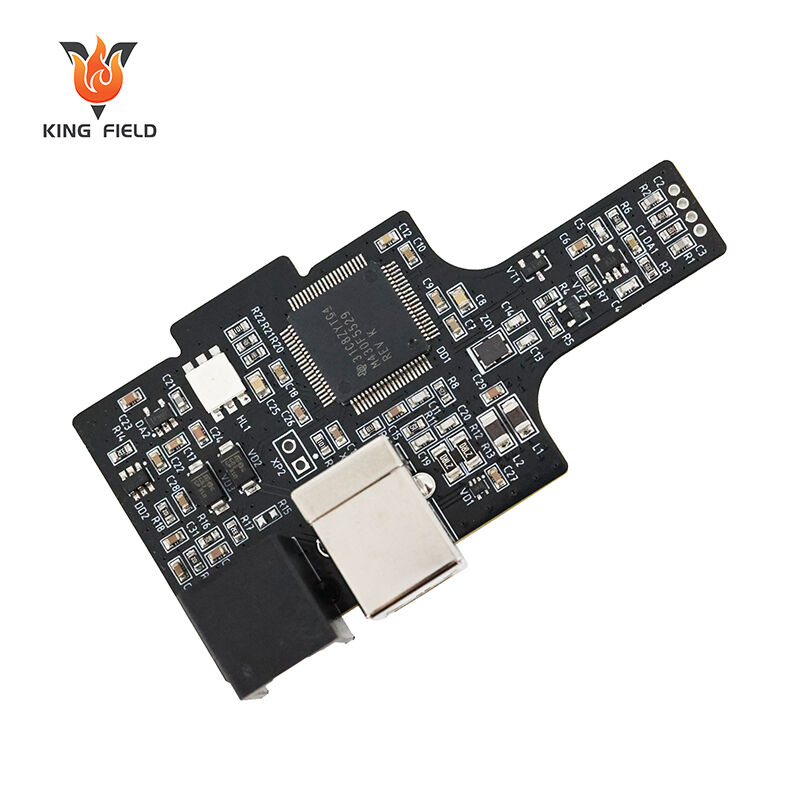

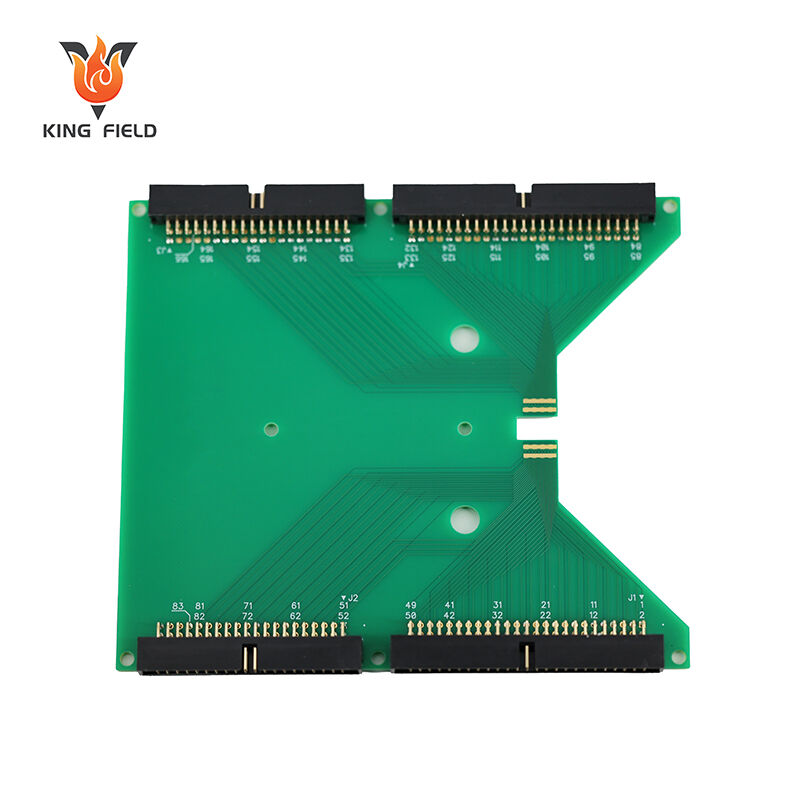

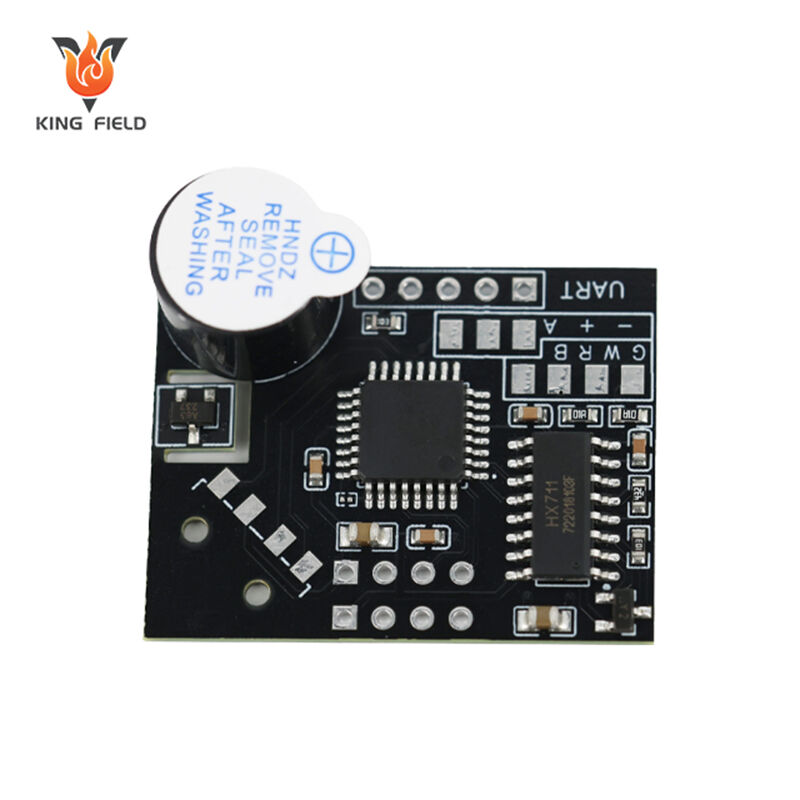

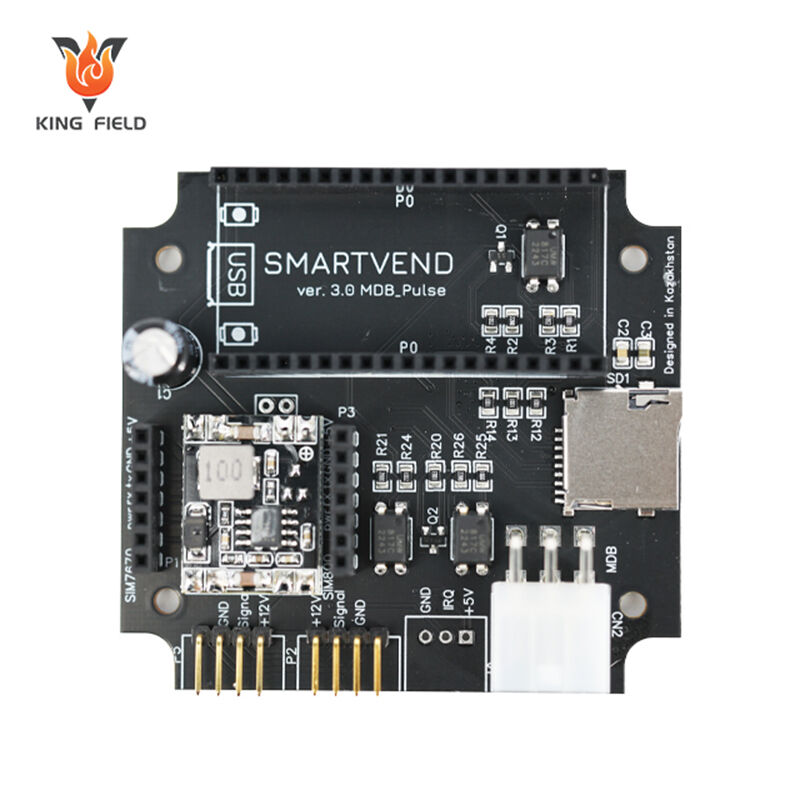

Prototype PCB Assembly

24h rapid prototyping, 48h delivery for 1–100 unit PCB prototypes. Includes BOM/DFM support & ICT/FCT testing. Specialized in medical/industrial/automotive/consumer electronics—accelerate your R&D, reduce risks.

Description

KING FIELD Prototype PCB Assembly:Fast, Reliable, Affordable Solutions

Prototype PCB Assembly – A Core Support for Modern Electronic Product Development.

In today's competitive electronics industry, rapidly transforming innovative concepts into functional prototypes is crucial for companies to gain a market advantage or fall behind. Prototype PCB assembly, which involves manufacturing small batches of circuit boards before mass production to test and verify electronic designs, is a pillar of product development. It helps engineers verify designs, identify problems, and optimize performance before mass production.

From consumer electronics to aerospace, companies across industries need to balance high quality and short time-to-market, creating a strong demand for rapid prototyping PCB assembly. It can significantly shorten development cycles, accelerate design iterations, and help companies launch innovative products ahead of time.

Analysis of rapid prototype PCB assembly

Why Can It "Transform Rapidly"

The core of rapid prototyping PCB assembly is a short full cycle. The design, manufacturing, assembly and testing stages can be delivered within 24 hours to 7 days depending on the complexity. Efficiency stems from streamlined processes, dedicated prototype production lines, and strategic cooperation between manufacturers and assembly plants.

It differs from the traditional model of mass production efficiency in that it is more flexible and capable of handling small batches: Settings can be adjusted quickly, simple boards can be delivered the next day, and manually welded components are faster than those that require templates or SMT programming.

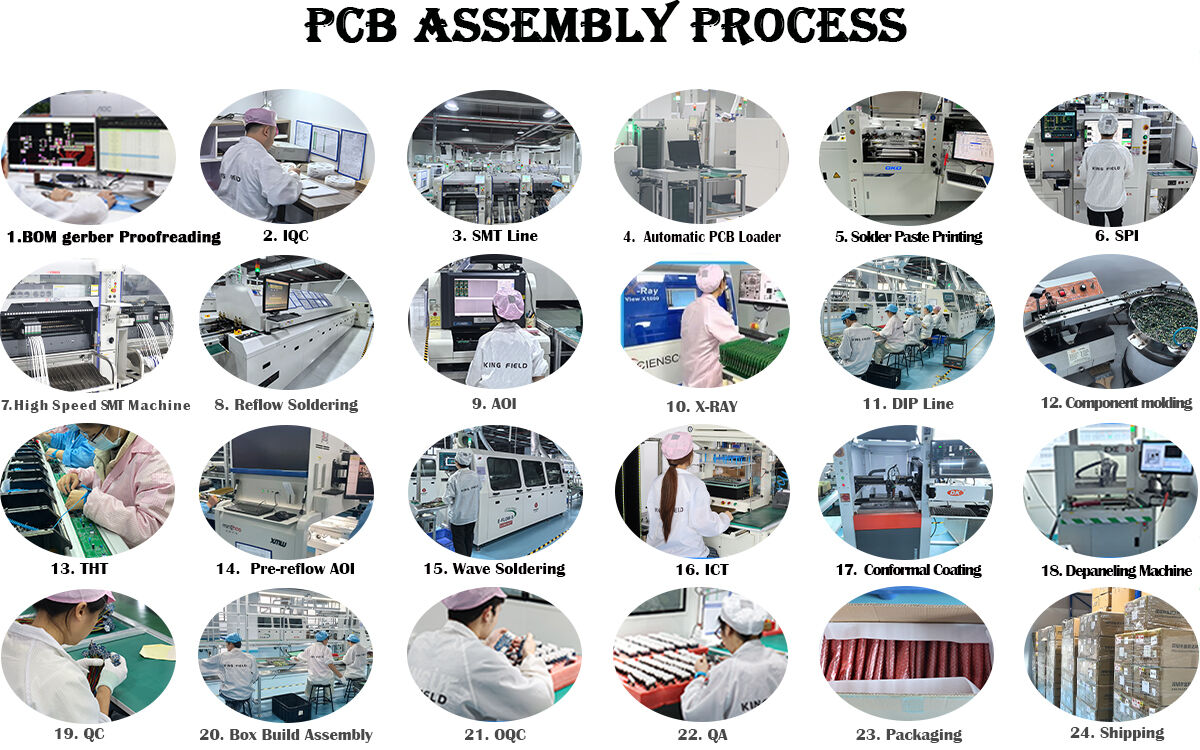

Core Processes

DFM analysis: Before production starts, professional engineers review the design documents and identify assembly challenges in advance to avoid rework later.

Component procurement: We have a stock of commonly used parts and rely on distributors for cooperation. Our procurement team understands the demands and efficiently coordinates with suppliers to ensure supply.

Assembly and testing: Utilizing automatic SMT and through-hole technology, we adopt SMT+ through-hole assembly technology, combined with AOI optical inspection, X-Ray inspection, and functional testing to ensure that each PCB meets the standards. Whether for rapid assembly or mass production, all undergo strict testing.

Prototype PCBA Application Areas

Our Expertise

Industrial Control

PLC, frequency converters, HMl, sensor control boards,

industrial inspection and control boards, etc.

Automotive Grade

- Automobiles: Tailgate, side door, seat,window, wiper, sunroof.

- seat massage control boards, and motor sensor boards.etc.

- Two-wheel electric vehicles: Mainboards,dashboard boards,navigation boards, front and rear headlight boards.

Medical and Medical Aesthetics &Wellnes

- Medical:Smart hospital control boards,glucose meter/oximeter/blood pressure monitor boards, and other medical instrument boards,ventilator and oxygen concentrator control boards.

- Medical Aesthetics & Wellness: Facial cleansing devices,hair removal devices, fascia guns,body fat scales, head massage devices.

Consumer Electronics

MP4, Bluetooth speakers, grill control boards,smart mouse and kevboard,children's learning tablets, smart home devices, kitchen appliances.

Quality assurance

Speed Advantage: How Fast Can Rapid Prototyping PCB Assembly Be?

Industry-Leading Turnaround Time

- 24-Hour Express Delivery: Kingfield is renowned for its rapid response to demand and short turnaround times, completing simple designs in as little as 24 hours.

- Turnaround Time Options: We offer turnaround time options for PCB prototypes in one day, 24 hours, 3 days, and 5 days.

- Standard Fast Turnaround: Most suppliers offer standard fast turnaround services of 3-5 days for complex components.

Key Factors Affecting Turnaround Time

- Design Complexity: The more complex the component, the more complex the process; HDI boards, multilayer laminates, and advanced via structures all require additional processing time.

- Component Availability: If components need to be procured, components with a 12-week delivery period will slow down the process. Proper planning and component selection are key to fast delivery.

- Assembly Method: Small-batch manual assembly and large-batch automated SMT differ in speed and cost; depending on the project quantity and soldering difficulty, manual or surface mount technology (SMT) soldering is selected.

Multi-layered Quality Control: Prototype Assembly Quality Inspection Methods

KING FIELD employs multiple rounds of inspection to build a comprehensive quality defense system:

- Automated Optical Inspection (AOI): For example, Green Circuits uses high-resolution cameras to accurately capture soldering errors, missing components, and misalignments, controlling assembly precision from the source.

- X-ray Inspection: Specifically designed to solve the inspection challenge of hidden solder joints on the bottom of components such as BGAs and QFNs, visually presenting solder joint quality and eliminating potential problems.

- In-Circuit Testing (ICT): Through electrical testing, verifying the connectivity of the circuit board, ensuring component values meet standards, and troubleshooting basic circuit faults.

- Functional Testing: Taking Makerfabs as an example, all PCBAs undergo full-function testing to ensure 100% pass rate, guaranteeing that the assembled product fully meets design specifications.

High efficiency

Prioritizing efficiency: Balancing quality and low cost in prototype production

PCB Prototype Assembly Pricing Analysis

PCB assembly unit prices vary significantly, depending on complexity, production volume, and customization requirements. Understanding costs can optimize budgets.

Core Costs

- Setup Costs: Primarily NRE (Network Equipment) fees, including one-time investments such as stencils and programming, unrelated to order volume.

- Component Costs: The highest percentage, including component prices and procurement costs.

- Assembly Labor: $0.02-$0.05 per square inch, affected by labor and operating costs.

Cost Optimization

- Bulk Volume: While small batches may seem cheaper, large batches significantly reduce unit prices.

- Geography: Assembly prices in North America are 3-4 times higher than in Asia; consider using Asian supply chains.

- Design: Simplify designs and use standard components to reduce costs.

Affordable Services

- Kingfield offers a $1 PCB discount, ideal for makers and startups.

-

Open Parts Library (OPL) contains over 150,000 local parts; full sourcing allows for production within 7 days.

Technical Strength: Cutting-edge Assembly Technology

I. Surface Mount Technology (SMT)

- Component Size: Our SMT processing covers BGA, QFN, and other sizes, compatible with 03015 ultra-small form factors.

- Precision Mounting: Kingfield can mount multilayer boards and rigid-flex boards.

- High-Density Boards: Our team can handle fine-pitch components on FR-4 boards.

II. Hybrid Assembly Technology

- Process Combinations: We offer a full range of services including SMT + through-hole, through-hole assembly, hybrid assembly, and rigid-flex boards.

- Flexible Manufacturing: Production lines can be flexibly configured with automated/manual component loading stations.

III. Industry Applications

- Consumer Electronics: Facilitating rapid iteration of mobile phones and wearable devices.

- Internet of Things (IoT): Supporting the development of home/industrial IoT devices, balancing functionality and cost.

- Medical Devices: Ensuring high reliability according to IPC Level 3 standards.

- Automotive Electronics: Meeting the needs of in-vehicle entertainment, engine control, and other systems.

Select Kingfield

Choose a reliable prototyping and assembly partner, KING FIELD

Core Selection Criteria

I. Key Evaluation Items

- Technical Strength: Select suppliers with sufficient experience in specific technologies, focusing on their ability to handle fine-pitch BGAs and micro/irregular components.

- Quality Certification: Must comply with IPC-A-610-D and ANSI/J-STD-001, meeting Category II and Category III standards.

- Delivery Efficiency: Prioritize suppliers offering rapid turnaround services such as 1/2/5-day PCB assembly and 1-day PCB prototyping.

II. Location Considerations

- Local CM (Contract Manufacturing) facilitates faster delivery;

-When selecting domestic or international suppliers, weigh cost, speed, and communication efficiency.

Rapid assembly future trend

- Automation and AI: By 2026, AI will be integrated into PCB assembly, potentially reducing costs by 20%, optimizing component placement, reducing errors, and improving efficiency.

- Advanced Technology: 3D printing may reshape the cost of PCB prototyping; by 2025, more convenient and affordable 3D-printed PCB options are expected.

-Sustainability: The electronics industry's emphasis on environmental protection will drive the adoption of more green PCB materials, propelling material and process innovation.

The Strategic Value of Rapid Prototyping Assembly

Rapid prototyping PCB assembly has evolved from an "extra service" for urgent projects into an essential capability for competitive product development. It accelerates prototyping, testing, and optimization by rapidly producing circuit boards, shortening time-to-market for electronic products.

Currently, high-quality prototyping assembly services combine speed, reliability, and cost-effectiveness, helping companies accelerate innovation, reduce risk, and launch higher-quality products. Whether a startup or a mature company, choosing the right rapid delivery partner is key to success.

In the rapidly evolving electronics industry, companies that effectively utilize this technology can maintain their competitive edge and quickly transform ideas into products. The future belongs to companies that can rapidly prototype, iterate, and scale, and this technology is a core enabler.

Want to accelerate your electronics projects? Partner with a seasoned supplier to experience the speed, reliability, and cost-effectiveness they offer.

Equipment parameters

| Equipment manufacturing process capability | |

| SMT Capacity | 60,000,000 chips/day |

| THT Capacity | 1.500,000 chips/day |

| Delivery Time | Expedited 24 hours |

| Types of PCBs Available for Assembly | Rigid boards, flexible boards, rigid-flex boards, aluminum boards |

| PCB Specifications for Assembly |

Maximum size: 480x510 mm; Minimum size: 50x100 mm |

| Minimum Assembly Component | 01005 |

| Minimum BGA | Rigid boards 0.3 mm; Flexible boards 0.4 mm |

| Minimum Fine-Pitch Component | 0.2 mm |

| Component Placement Accuracy | ±0.015 mm |

| Maximum Component Height | 25 mm |

FAQ

1. What service do you have?

KING FIELD: We are a high-tech enterprise specializing in one-stop electronic design and manufacturing. Our integrated manufacturing platform covers front-end R&D design, optimized component procurement, precision SMT assembly, DIP plug-in, complete product assembly, and full-function testing.

2. How can we ensure our information should not let third party to see our design?

KING FIELD: We are willing to sign NDA effect by customer side local law and promising to keep customers data in high confidential level.

3.What are the main products of your PCB/PCBA services?

KING FIELD: We have deep expertise in high-end manufacturing fields such as industrial control, automotive standards, medical, and health & wellness. The stringent quality control experience we have accumulated will be directly applied to your products.

4. Is KING FIELD a factory or trade company?

KING FIELD: KING FIELD is a 20+year experienced professional contract manufacturer to provide one stop Turnkey PCB assembly and electronics manufacturing service.

5. What files required to get quotation from you?

KING FIELD: For OEM PCBA projects, please provide the Gerber data/files and indication of related technical requirements as well as any special requirement if you have; For ODM projects, please provide Function List, so our engineer team can work on it.

6. How long does it take for PCBA quote?

KING FIELD: Depend on project's complexity. Normally 1-2 day is enough for our engineers to evaluate.

7. Do you have any minimum order quantity (MOQ) requirement?

KING FIELD: No, we do not have MOQ requirement, we can support your projects starting from prototypes to mass productions.