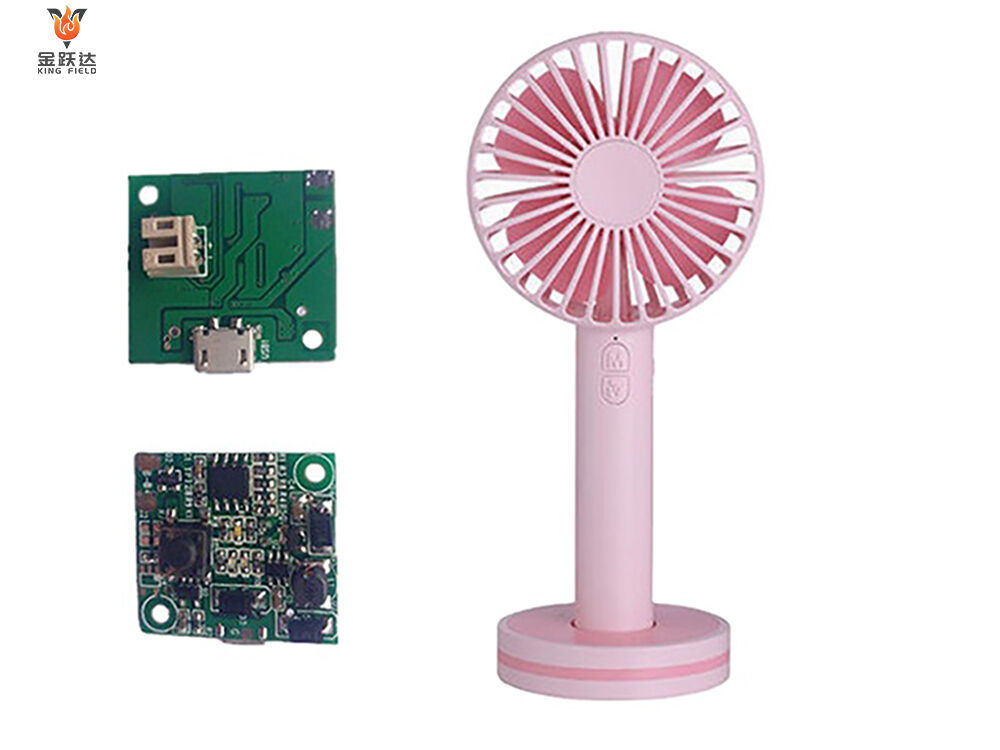

Consumer Electronics

Section 1: Resonance with Industry Pain Points

• Complex supply chain, risks of mixed material batches and counterfeit components, difficulty in traceability, and frequent after-sales complaints;

• Rapid new product iteration (3-6 months/model), long prototyping cycle, low trial production yield, and missing the market launch window;

• Consumer electronics products are trending towards thinner and lighter designs, which places high demands on high-density interconnect (HDI) PCBs.

Section 2, Our Industry Solutions

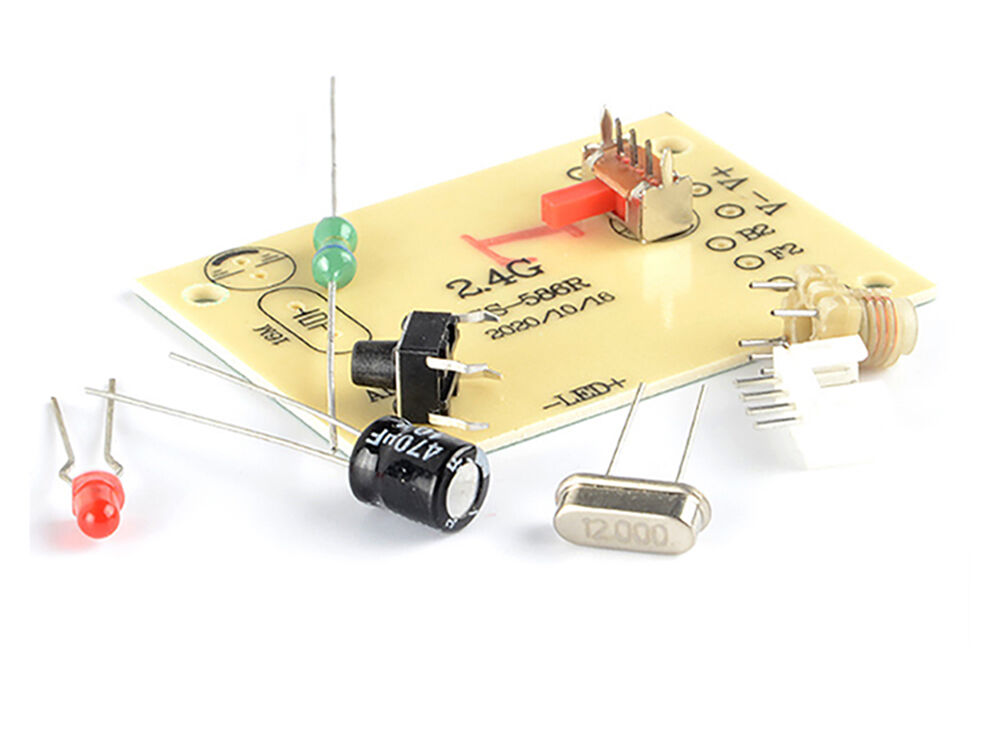

• Design Phase: Utilizes HDI blind/buried via design, rigid-flex PCB, and optimized power management.

• Manufacturing Phase: 01005 Ultra-fine Pitch Patch + 3D AOI Inspection,support LGA/BGA packaging, 24-hour rapid prototyping.

• Full-process traceability system: Real-time collection of SMT placement parameters, reflow soldering profiles, and AOI inspection results; offline storage is supported.

Section 3, Real-world Project Cases

Smart wearable device manufacturer: Kingfield provides smartwatch PCBA products. Kingfield enables rapid switching of device parameters, mounting of 01005 components, 72-hour global sourcing of scarce components, BOM optimization, and a fast response time within a 3-month iteration cycle.

Section 4, Authoritative Certificates

• Compliant with IPC-A-610 Class 3 standards, ISO9001/ISO14001 system certifications;

• ESD 20.20 electrostatic discharge protection certification, RoHS 2.0, and REACH certifications;

• Serving over 500 consumer electronics companies with a 90% repurchase rate.

| 5 technical indicators | 1. Thickness Limit: Enables ultra-thin 0.4mm board design, suitable for foldable screens and smart wearable devices. | |

| 2. Signal transmission efficiency: high-speed signal loss ≤ 0.3dB/inch Wi-Fi 6E throughput ≥1.2Gbps. | ||

| 3. Environmental standards: Compliant RoHS. The directive mandates 100% coverage of the lead-free tin plating (HASL) process. | ||

| 4. Reliability: Passed 1000 times insertion/drop test. | ||

| 5. Power consumption: Standby power consumption < 5mW, Operating power consumption < 1.5W | ||

| 3 industry pain points | 1. Short iteration cycle: The product iteration speed is fast, requiring quick response to design changes and small-batch trial production needs. | |

| 2. User experience optimization: Balancing power consumption, heat dissipation, and performance is necessary. | ||

| 3. High integration and small size: Consumer electronics products are trending towards thinner and lighter designs, which places high demands on high-density interconnect (HDI) PCBs. | ||