A Guide to FR4 Material in Printed Circuit Board Design. Choose FR4 material for your custom circuit board to ensure durability, stable performance, and cost-effectiveness in any PCB design or manufacturing project. Explore FR4 material in PCB fabrication. Learn why FR4 PCBs are widely used, how to choose FR4 for your circuit board, and its excellent thermal properties

Explore FR4 material in PCB fabrication. Understand why FR4 PCBs are widely used in circuit board design for excellent thermal properties. Choose FR4 now.

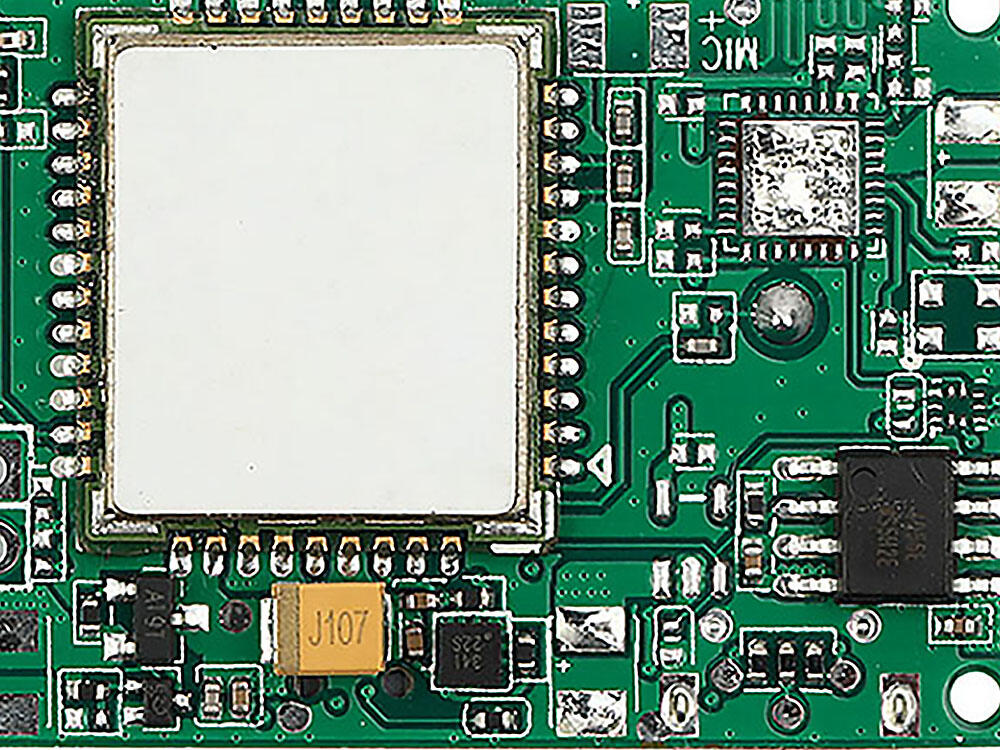

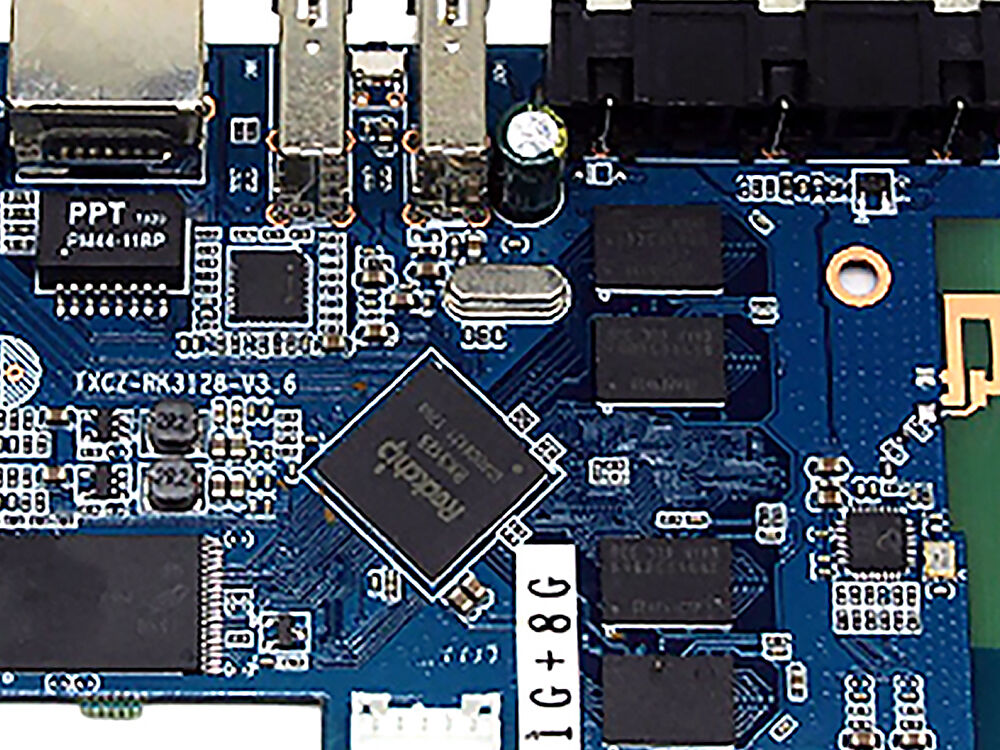

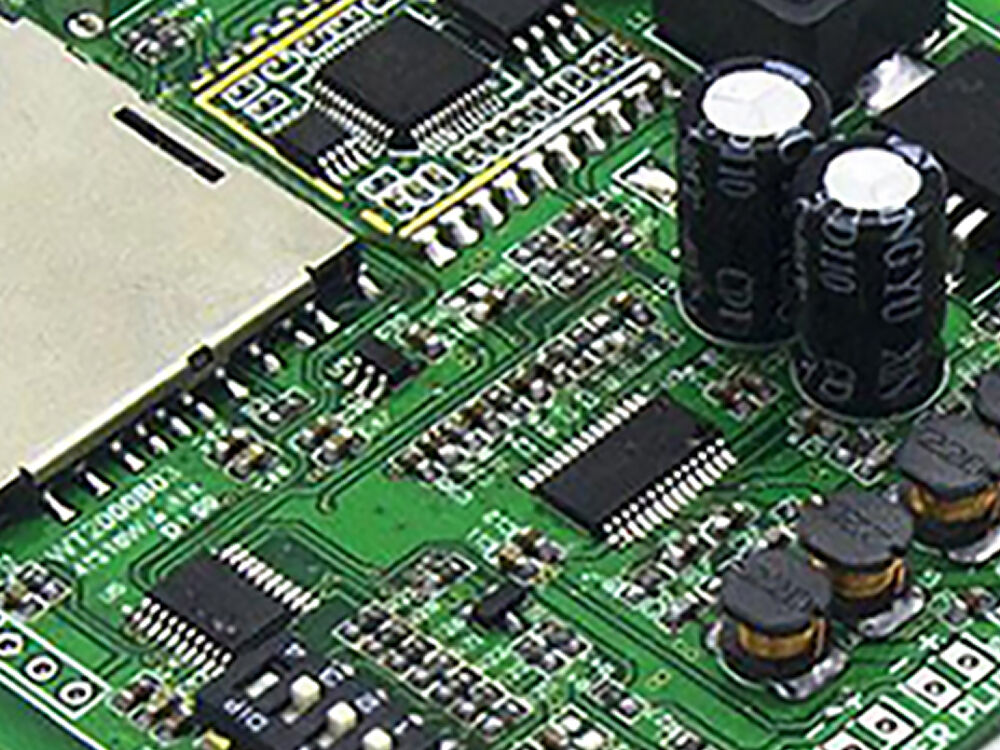

FR4 is the dominant base material for PCB fabrication, a glass-reinforced epoxy laminate compliant with IPC-4101 standards—"FR" denotes UL94 V-0 flame retardancy, "4" the fourth iteration of this laminate series—composed of woven glass fiber cloth (reinforcement), epoxy resin (bonding matrix), and laminated copper foil, forming a rigid, durable substrate for circuitry; it has replaced inferior materials like paper-based phenolic laminates by combining mechanical stability, reliable electrical performance, cost-effectiveness, and easy manufacturability, perfectly matching modern electronics’ demands for miniaturization, high operating temperatures, and complex circuitry, while its versatility meets sector-specific needs: medical devices, automotive electronics, and consumer electronics; this introduction outlines FR4’s core composition, key advantages, and universal applicability, with room for deeper exploration of technical specs, alternative material comparisons, and industry-specific optimizations in subsequent content.

Meets UL94 V-0 standard (self-extinguishes within 10s, no flammable dripping). Flame retardancy comes from glass fiber/epoxy resin composition (flame-retardant additives in epoxy, glass fiber as flame barrier), complying with global safety regulations for medical, automotive, and industrial control industries.

Maintains stability at -50°C to 115°C. Resists brittleness in low temps and resin softening in high temps, eliminating the need for specialized thermal protection and reducing design/manufacturing costs.

Standard Tg: 135–150°C; high-Tg grade: >170–180°C. Critical for lead-free soldering (240–260°C) and devices with frequent thermal cycles, preventing warping, delamination, or copper foil peeling.

Composite structure delivers excellent strength-to-weight ratio and rigidity. Resists deformation during assembly and long-term use, ensuring component positional accuracy for precision devices and enduring mechanical stress for extended service life.

Stable dielectric constant (Dk: ~4.3–4.8) for consistent signal propagation; low dissipation factor (Df) for energy efficiency; high surface resistivity for insulation between traces. Ideal for most digital and analog circuits.

Dense structure avoids moisture-related issues (delamination, copper corrosion). Suitable for marine, outdoor, and humid environments (e.g., medical operating rooms) without additional waterproof coating.

Globally sourced raw materials and mature processes enable cost-efficiency for prototypes and mass production. Fully compatible with standard PCB fabrication (drilling, etching, plating), reducing lead times and manufacturing thresholds.

Global FR4 market is dominated by reputable suppliers adhering to IPC-4101 standards, providing consistent quality and technical support (critical for automotive/medical industries). Key manufacturers include Isola (USA), Nelco (USA), Ventec (Taiwan, China), Panasonic (Japan), and SHENGYI (China).

Below is a detailed comparison table of mainstream FR4 materials from top manufacturers, highlighting core parameters and application advantages:

|

Manufacturer |

Material |

Tg (°C) |

Dk (1MHz) |

Moisture Absorption (%) |

Key Features |

|

Isola |

370HR |

180 |

4.2–4.5 |

0.15 |

High-Tg grade optimized for lead-free soldering; low moisture absorption ensures reliability in harsh environments; ideal for automotive and industrial control PCBs |

|

Nelco |

N4000-13 |

150 |

4.3 |

0.18 |

Standard FR4 with excellent dielectric constant stability; cost-effective for general-purpose applications; suitable for consumer electronics and basic industrial devices |

|

Ventec |

VT-47 |

170 |

4.4 |

0.12 |

High-performance mid-Tg grade; ultra-low moisture absorption and stable electrical properties; well-suited for medical devices and high-reliability industrial equipment |

|

SHENGYI |

S1141 |

140 |

4.4–4.6 |

0.16 |

Cost-competitive standard grade; balanced mechanical and electrical performance; widely used in mass-produced consumer electronics and low-power industrial PCBs |

|

Panasonic |

R-1766 |

155 |

4.3 |

0.17 |

High-temperature resistance and good dimensional stability; suitable for automotive electronics and precision instruments |

While FR4 is versatile, it has inherent limitations that restrict its use in specialized applications, requiring careful consideration during material selection:

FR4’s epoxy resin matrix has limited thermal conductivity and voltage resistance compared to specialized materials. In high-power, high-voltage applications (e.g., power inverters, high-voltage power supplies), prolonged exposure to high temperatures can cause resin degradation, and excessive voltage may lead to insulation breakdown. This limits its use in devices with high current density or operating voltages exceeding 1kV, where materials like ceramic substrates or polyimide are more suitable.

Controlled impedance is critical for high-speed signal transmission, but FR4’s dielectric constant (Dk) exhibits variability at higher frequencies (above 1GHz). This variability leads to inconsistent impedance values across the PCB, causing signal reflections, crosstalk, and impedance mismatches. In high-speed RF designs (e.g., 5G communication modules, radar systems), this limitation can severely affect signal integrity, making FR4 less ideal than low-Dk materials like Rogers laminates.

FR4’s dissipation factor (Df) increases with frequency, resulting in significant signal attenuation at GHz-range frequencies. Compared to specialized high-frequency materials (e.g., PTFE, Rogers 4000 series), which have ultra-low Df, FR4 suffers from higher energy loss in microwave and millimeter-wave applications. This makes it unsuitable for radar systems, satellite communication equipment, and other high-frequency electronic devices that demand minimal signal loss.

Selecting the appropriate FR4 grade requires aligning material properties with the PCB’s design requirements, operating environment, and manufacturing process. Below are actionable guidelines:

FR4 substrate thickness ranges from 0.2mm (ultra-thin) to 3.2mm (thick), with the choice dependent on application needs: Thin FR4 (≤0.8mm) offers flexibility and space-saving advantages, making it ideal for compact devices like mobile phones, wearables, and slim industrial sensors; thick FR4 (≥1.6mm) provides enhanced mechanical durability and structural support, suitable for large-size PCBs, high-power devices, and equipment subject to mechanical impact (e.g., industrial machinery control panels).

Opt for high-Tg FR4 (>150°C) when the PCB will undergo lead-free soldering (higher temperatures) or operate in high-temperature environments (e.g., automotive engine compartments, industrial ovens). Standard-Tg FR4 (135–150°C) suffices for low-temperature applications like consumer electronics, office equipment, and indoor sensors, offering a cost-effective alternative without compromising basic performance.

For high-speed digital or analog circuits (e.g., data center servers, communication routers), prioritize FR4 grades with stable dielectric constant (Dk) across the operating frequency range. A stable Dk ensures consistent signal propagation and minimizes signal distortion, critical for maintaining data transmission accuracy and device performance.

Leverage manufacturer-provided resources to make informed decisions: Use online tools like material selectors (offered by Isola, Ventec, etc.) to filter materials by Tg, Dk, and moisture absorption; utilize impedance calculators to verify if the selected FR4 meets controlled impedance requirements; and reference Design for Manufacturing (DFM) handbooks to ensure the material is compatible with assembly processes (e.g., drilling, soldering, conformal coating).

IPC (Association Connecting Electronics Industries) standards establish strict quality criteria for FR4 PCBs, ensuring consistency and reliability across the industry. Two core standards relevant to FR4 are IPC-A-600 (Acceptability of Printed Boards) and IPC-6012 (Qualification and Performance Specification for Rigid Printed Boards):

IPC-A-600 specifies requirements for FR4 substrate surface quality, focusing on weave exposure and weave texture issues. Excessive weave exposure (where glass fiber cloth is visible through the resin) can weaken solder adhesion and affect the uniformity of the solder mask, while uneven weave texture may cause component mounting inaccuracies. These defects are classified by severity, with Class 3 (for high-reliability applications like medical and aerospace) requiring strict adherence to surface smoothness standards.

IPC-6012 addresses subsurface defects in FR4 substrates, including measling (fine cracks in the resin), crazing (network of microcracks), delamination (separation of layers), blisters (air or moisture pockets), and foreign material contamination. These defects severely impact the reliability of multi-layer and high-density PCBs, as they can lead to electrical short circuits, mechanical failure, or premature device breakdown. The standard mandates rigorous inspection (e.g., X-ray, ultrasonic testing) to detect subsurface defects, especially for critical applications in automotive and aerospace sectors.

Despite its widespread use, FR4 is not suitable for specialized applications with extreme requirements. Alternative materials should be considered in the following scenarios:

FR4’s balanced performance and cost-effectiveness make it the substrate of choice across diverse industries, with key applications including:

When engineers discuss PCB fabrication or PCB manufacturing, the term FR4 is nearly synonymous with the foundation of modern electronics. At its core, FR4 is a composite material that forms the main structural and electrical backbone of most printed circuit boards used today. But FR4 is much more than just a “PCB substrate”; it is a fascinating blend of material science, safety certification, and engineered performance.

FR4 is an abbreviation for “Flame Retardant 4” — a standard set by the National Electrical Manufacturers Association (NEMA) for glass fiber reinforced epoxy laminates. The “FR” stands for Flame Retardant, a property critical for safety in all electronics, ensuring that the material will self-extinguish and inhibit the spread of fire. The “4” differentiates it from other NEMA specifications, making it easy for designers and engineers to specify a material with predictable performance and global recognition.

Key facts about FR4:

At a technical level, FR4 is a glass-fiber reinforced epoxy resin laminate. This means it’s essentially a composite: layers of tightly woven fiberglass cloth (for strength) are impregnated with epoxy resin (for adhesion, insulation, and mechanical integrity). The resulting FR4 sheets serve as PCB base material, offering an outstanding mix of electrical insulation, mechanical strength, and cost-effectiveness.

The role of FR4 material in PCB fabrication can be summarized as:

“FR4’s blend of flame retardancy, mechanical strength, and electrical insulation is unmatched by any single alternative for general-purpose PCB fabrication.” — Materials Engineer, IPC Standards Committee

From small-batch PCBs for startups and prototyping to high-volume multilayer PCBs in aerospace or automotive applications, FR4’s unmatched balance of performance, safety, and cost makes it the go-to dielectric material:

|

Property |

Description |

|

Full Name |

Flame Retardant 4 (FR4) |

|

Base Material |

Glass-reinforced epoxy laminate |

|

Key Certification |

UL94V-0 (Flame Retardant) |

|

Main Uses |

PCB substrate, prepreg, copper-clad laminate |

|

Electrical Properties |

High dielectric constant, low Df |

|

Mechanical Properties |

High strength, rigidity, dimensional stability |

|

Typical Thickness Range |

0.2 mm to 3.2 mm (customizable) |

FR4 material has become the benchmark for PCB substrate materials not just due to its technical properties, but also for its proven reliability and global standardization. Its combination of glass fiber and epoxy resin offers a unique synergy—making it more than just a commodity, but rather the heart of countless innovations in electronics.

FR4 stands as the industry-standard PCB substrate due to its unbeatable balance of durability, cost-effectiveness, reliable insulation, and robust mechanical-electrical performance, satisfying the core needs of consumer electronics, automotive, industrial control, and medical sectors. However, it is not suitable for advanced high-frequency applications (e.g., 5G, radar) or extreme environments (high radiation, harsh chemicals) where specialized materials are required. The key to optimal use lies in matching FR4’s grade, thickness, and properties precisely to project requirements—such as high-Tg grades for lead-free soldering or ultra-thin variants for compact devices.

Standard FR4: 0.15–0.20% (24h immersion at 23°C); high-performance grades: 0.12–0.15%, ideal for humid/marine environments.

Dk decreases with frequency: 4.3–4.8 at 1MHz (stable for low-speed use); 3.8–4.2 at 1–10GHz. High-performance FR4 minimizes this variability for high-speed circuits.

Yes. Ultra-thin FR4 (0.2–0.8mm) suits wearables/foldable devices; large-format FR4 (exceeding 500mm×600mm) uses low-CTE, high-rigidity grades to avoid warping.

Non-hazardous under global standards. Recyclability is limited, but copper foil can be extracted and reused; the remaining glass fiber/resin mix is landfilled or used as construction aggregate.

Compatible with lead-free soldering (240–260°C) when using high-Tg FR4 (>170–180°C); standard Tg (135–150°C) risks warping or delamination.

Hot News

Hot News2026-01-17

2026-01-16

2026-01-15

2026-01-14

2026-01-13

2026-01-12

2026-01-09

2026-01-08