Introduction

Startups and small businesses face unique challenges when developing electronic products. Limited capital, constrained technical resources, and tight development timelines often make it difficult to build robust manufacturing processes in-house. Navigating complex supply chains, sourcing components, managing quality control, and overseeing assembly logistics can be costly and overwhelming.

Full turnkey PCB assembly presents a comprehensive, end-to-end solution that empowers startups and small businesses to bypass costly infrastructure investments and manufacturing hurdles. By outsourcing the entire PCB manufacturing and assembly cycle—from PCB fabrication and component sourcing through assembly, testing, and final packaging—companies can focus on core competencies such as product design, innovation, and market strategy. Meanwhile, their trusted turnkey partner handles production with professional expertise and state-of-the-art technologies.

Why Full Turnkey PCB Assembly is a Game Changer for Startups

- Cost-Effective: Avoids heavy upfront investments in factory space, machinery, and skilled labor.

- Access to Expertise: Leverages providers’ deep manufacturing experience and advanced technologies like Automated Optical Inspection (AOI) and In-Circuit Testing (ICT).

- Scalable: Easily adjusts production volume from prototypes to mass production as market needs evolve.

- Accelerated Time-to-Market: Streamlines operations by integrating the entire supply chain, slashing lead times.

- Quality & Compliance: Ensures products meet stringent industry standards with rigorous quality assurance.

“For startups, turnkey PCB assembly is not just outsourcing — it’s a strategic partnership that accelerates innovation and maximizes limited resources.” — John William, Electronics Industry Consultant

This article explores the full spectrum of turnkey PCB assembly services, explains their benefits specifically for startups and small businesses, and offers practical advice on selecting the right PCB assembly provider to ensure successful product development and market entry.

Choosing the Right Full Turnkey PCB Assembly Provider

Selecting the ideal turnkey PCB assembly provider is a critical decision for startups and small businesses seeking reliability, quality, and timely delivery. The right partner can streamline your product development, reduce risks, and ensure your electronic device meets market and regulatory demands.

Key Criteria to Evaluate

1. Experience and Expertise

- Look for providers with a proven track record in PCB manufacturing and assembly, particularly with startups or small batch production.

- Ensure familiarity with your industry’s standards, whether consumer electronics, medical, automotive, or telecom.

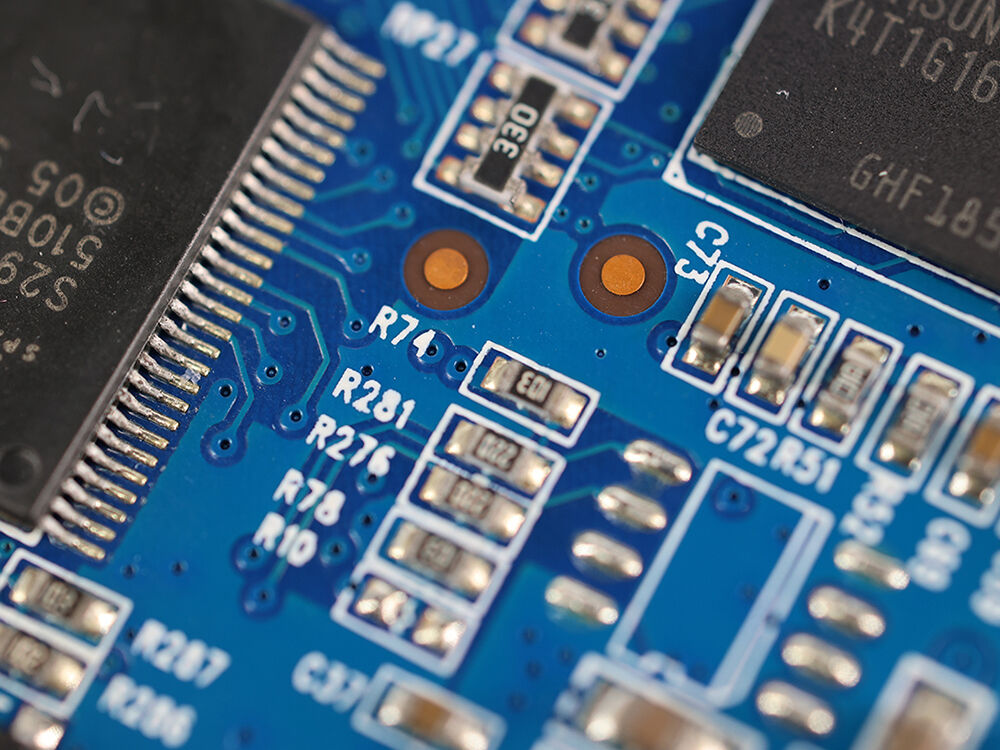

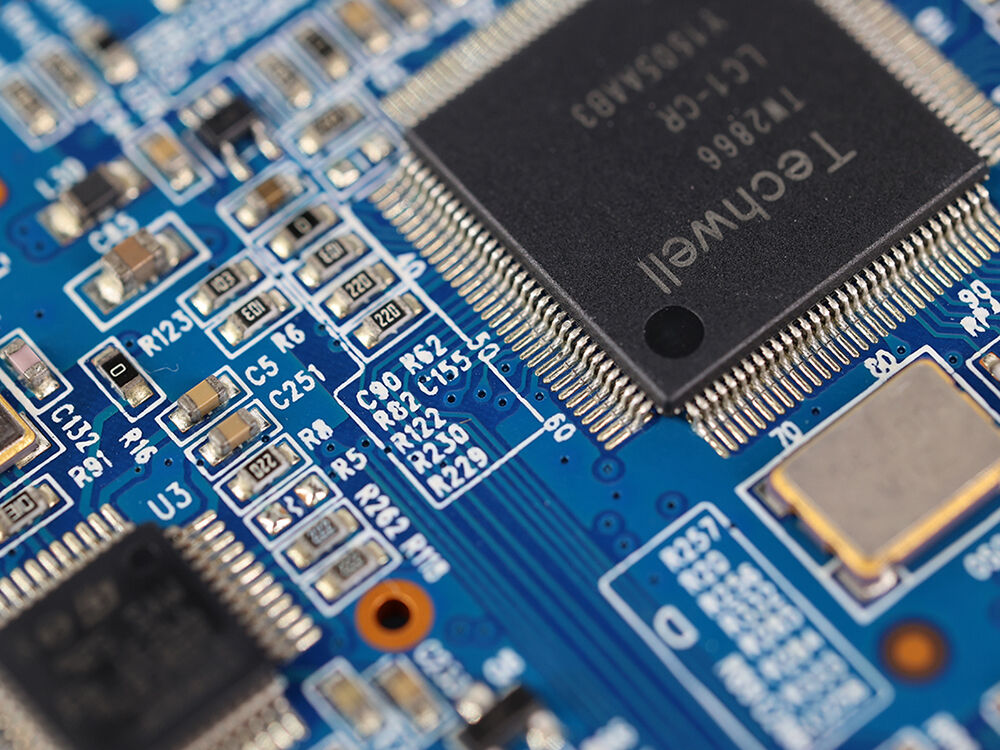

- Expertise in SMT (Surface Mount Technology) and THT (Through-Hole Technology) assembly allows handling complex mixed-technology boards with precision.

2. Manufacturing Capabilities

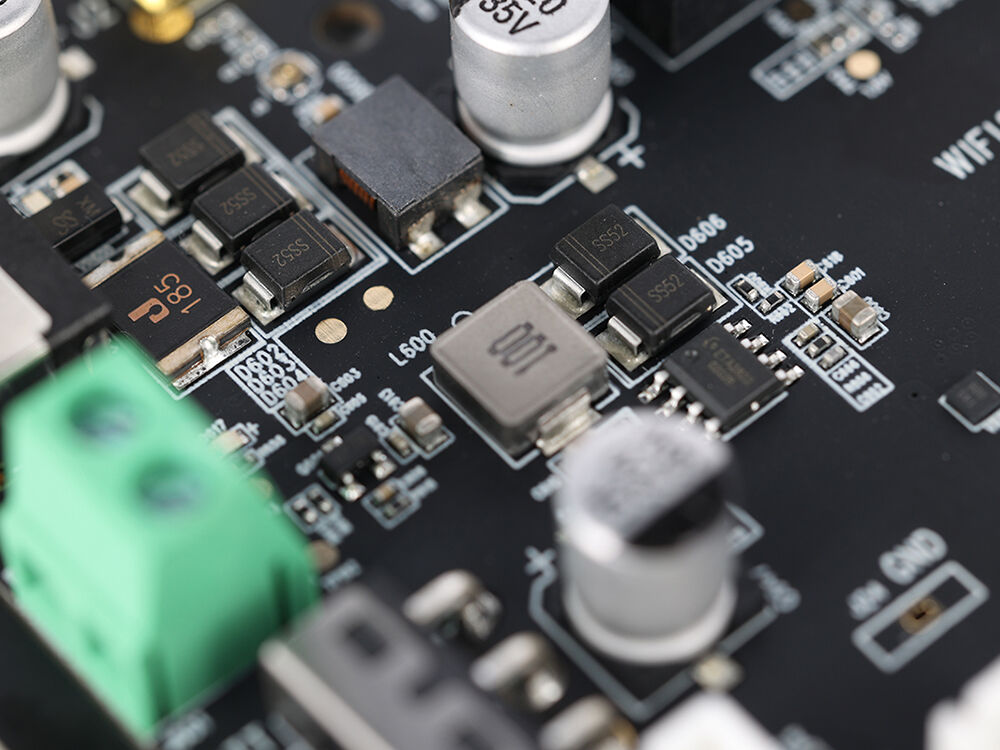

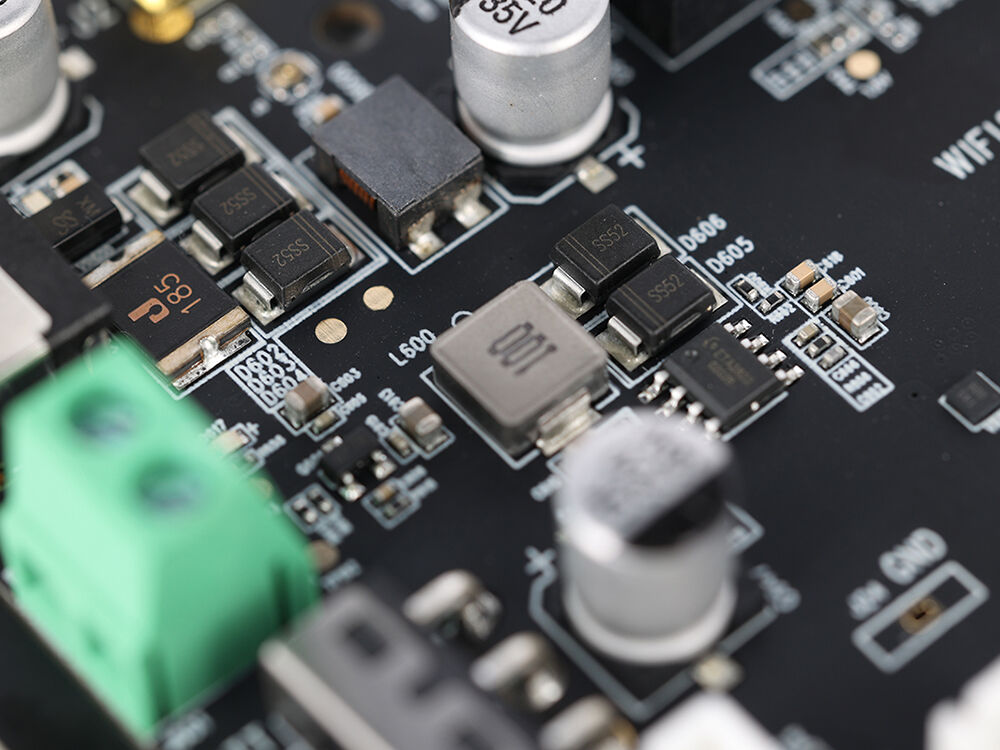

- Evaluate manufacturing infrastructure: advanced PCB fabrication lines, pick-and-place machines, automatic soldering (reflow, wave), and assembly stations.

- Capacity to handle multilayer, HDI, BGA, or high-density designs.

- Availability of prototype, pilot, and large-volume production to support scalability.

3. Quality Control and Certifications

- Check for recognized certifications such as ISO 9001 (quality management) and, where applicable, ISO 13485 for medical device manufacture.

- Confirm the use of thorough quality assurance practices: AOI, ICT, functional testing, X-ray inspection, and traceability systems.

- Commitment to continuous improvement and defect reduction programs.

4. Component Sourcing and Supply Chain Management

- Ensure the assembler maintains strong supplier relationships and offers efficient, transparent component procurement.

- Ability to manage long lead-time parts and optimize bill of materials (BoM) cost and availability.

- Verify if the provider can offer consignment inventory, kitting, or inventory management services.

5. Communication and Support

- Choose a provider who offers clear, consistent communication with project management support.

- Transparency in project status, timely responses to queries, and collaborative problem-solving culture.

- Capability to assist in Design for Manufacturability (DFM) reviews and engineering change orders (ECO).

6. Pricing and Turnaround Times

- While cost is important, evaluate value over price—consider quality, reliability, and supplier support.

- Compare turnaround times for prototypes, short runs, and scale-up production aligned with your business goals.

- Check for flexibility in accommodating urgent or quick-turn orders.

7. Intellectual Property Protection

- Verify that the provider maintains strict confidentiality policies.

- Review non-disclosure agreements (NDAs) and data handling procedures.

- Ensure secure handling of design files, source code (if applicable), and project information.

Provider Evaluation Checklist

|

Criterion

|

Key Questions to Ask

|

|

Experience

|

Have you served startups/small businesses?

|

|

Manufacturing capabilities

|

What assembly technologies do you support?

|

|

Quality certifications

|

Which ISO or industry standards do you comply with?

|

|

Component sourcing

|

How do you manage component shortages?

|

|

Communication

|

How often do you provide project updates?

|

|

Pricing and lead time

|

What are your typical turnaround times and pricing models?

|

|

IP protection

|

What security measures protect my IP?

|

Advantages of Full Turnkey PCB Assembly for Startups and Small Businesses

Leveraging full turnkey PCB assembly services offers a multitude of benefits tailored to the unique needs of startups and small businesses. By outsourcing the entire PCB manufacturing and assembly process, these companies can overcome traditional barriers to entry, accelerate innovation, and optimize their operational focus.

1. Focus on Core Competencies

Startups often have limited resources and workforce. Full turnkey assembly allows you to focus on:

- Product design and innovation: Free your technical team from manufacturing complexities.

- Business development: Allocate more time to market research, customer engagement, and sales.

- Brand building: Concentrate on differentiating your product and scaling your company.

2. Reduced Overhead and Capital Investment

Building in-house PCB assembly capabilities requires significant capital expenses:

- Procurement of expensive SMT and THT assembly lines.

- Skilled labor hiring and training.

- Quality control infrastructure (AOI, ICT, X-ray).

- Inventory management and warehousing.

Turnkey services eliminate these upfront costs, reducing financial risk and working capital requirements. This cost saving can be reinvested in R&D or market expansion.

3. Access to Advanced Technologies and Expertise

Turnkey providers continuously invest in state-of-the-art equipment and technologies including:

- High-speed pick-and-place machines for fast, accurate component placement.

- Automated optical inspection systems reducing defects.

- Sophisticated testing protocols like ICT, functional, and burn-in testing.

- Supply chain management tools ensuring reliable component sourcing.

4. Improved Time-to-Market

Integrated turnkey solutions minimize handoffs and communication delays by centralizing:

- PCB fabrication

- Component procurement

- Assembly, inspection, and testing

- Packaging and logistics

This streamlined approach accelerates production cycles, enabling startups to launch products faster and respond agilely to market feedback.

5. Scalability and Flexibility

Startups often experience fluctuating demand volumes. Full turnkey PCB assembly providers offer flexible scalability:

- Seamlessly scale from prototypes and low-volume pilot runs to mass production.

- Quickly adjust production schedules as market demand varies.

- Support for custom assembly requests or complex multi-step box builds.

6. Quality Assurance and Compliance

Ensuring compliance with industry standards and regulatory requirements is simplified through turnkey providers:

- Adherence to ISO 9001 and other certifications.

- Rigorous quality inspection processes (AOI, Flying Probe Testing, ICT).

- Traceability and documentation for audits and certifications.

- Reduced risk of warranty claims through superior quality control.

7. Supply Chain Management

Reliable supply chain management is one of the toughest challenges for startups:

- Turnkey providers maintain strong relationships with component suppliers, mitigating risks of part shortages.

- Inventory management services reduce carrying costs and prevent delays.

- Consolidated shipping and logistics reduce transit times and costs.

Summary Table: Benefits of Full Turnkey PCB Assembly for Startups and Small Businesses

|

Benefit

|

Description

|

|

Focus on Core Competencies

|

Enables startups to concentrate on innovation & growth

|

|

Reduced Overhead

|

Avoids capital expenditure on equipment & staff

|

|

Access to Advanced Tech

|

Leverages latest assembly and testing technologies

|

|

Faster Time-to-Market

|

Streamlined, integrated production accelerates launch

|

|

Production Scalability

|

Adapts efficiently to changing volume demands

|

|

Quality Assurance

|

Meets industry standards with robust QA/inspection

|

|

Supply Chain Reliability

|

Strong sourcing network and inventory support

|

Case Study

A wearable tech startup leveraged full turnkey PCB assembly services to navigate component shortages and complex multi-layer PCB assembly for their flagship fitness device. The streamlined manufacturing and dependable quality assurance led to a 30% reduction in time-to-market and over 40% cost savings compared to attempting in-house assembly.

Please let me know when you are ready for the next section: Potential Challenges and Considerations.

Potential Challenges and Considerations

While full turnkey PCB assembly offers substantial benefits for startups and small businesses, it’s important to be aware of and proactively manage potential challenges. Addressing these considerations early helps ensure a smooth partnership and successful product launch.

1. Intellectual Property Protection

Startups often handle sensitive designs and innovations. Entrusting your project to an external provider requires:

- Clear non-disclosure agreements (NDAs) and strict confidentiality policies.

- Secure data transfer and storage systems to prevent leaks.

- Transparency about subcontracting, if any, to avoid unauthorized access.

Ensuring robust IP protection builds trust and safeguards competitive advantage.

2. Communication and Collaboration

Effective collaboration is vital for complex turnkey projects:

- Maintain clear and frequent communication channels with your PCB assembly provider.

- Define roles and expectations upfront for engineering changes, design revisions, and urgent issues.

- Use project management tools or dashboards when available for real-time status updates.

Poor communication can lead to misunderstandings, delays, and quality issues.

3. Quality Control and Oversight

Even with reputable providers, startups should:

- Request and review quality documentation such as process audits, test reports, and certifications.

- Consider onsite or third-party audits if volume justifies it.

- Use pilot runs to validate quality before full production.

Active oversight reduces risks of receiving substandard assemblies or late defect discoveries.

4. Lead Times and Logistics

Turnkey PCB assembly often relies on global supply chains:

- Account for component lead times, especially in shortage-prone markets.

- Plan for shipping customs clearance, import/export regulations, and potential delays.

- Work closely with providers to monitor and mitigate supply disruptions.

Realistic lead time expectations facilitate better product launch planning and market responsiveness.

Recommendations to Mitigate Challenges

|

Challenge

|

Mitigation Strategy

|

|

Intellectual Property

|

Secure NDAs; use trusted providers with robust controls

|

|

Communication

|

Set regular updates; establish clear escalation paths

|

|

Quality Oversight

|

Review documents; pilot production; conduct audits

|

|

Lead Times & Logistics

|

Early ordering; buffer stock; transparent supplier communication

|

FAQ: Frequently Asked Questions About Full Turnkey PCB Assembly

1. What is the difference between full turnkey and partial turnkey PCB assembly?

Full turnkey PCB assembly means the provider manages the entire process—from PCB fabrication and component sourcing to assembly, testing, and delivery. You receive fully assembled, tested, and ready-to-use boards.

Partial turnkey PCB assembly involves your company supplying some or all components, while the provider handles fabrication and assembly. This option is suitable if you have existing inventory or unique sourcing preferences.

2. How does full turnkey PCB assembly contribute to cost savings?

By consolidating PCB fabrication, component procurement, assembly, testing, and packaging into one process, full turnkey assembly reduces overhead:

- Avoids investment in manufacturing equipment and workforce.

- Ensures volume buying power for better component pricing.

- Minimizes handling and logistics expenses through integrated supply chain management.

- Reduces risk of costly errors and rework via quality assurance expertise.

3. What are typical quality control measures used by turnkey PCB assembly providers?

Leading turnkey providers employ a range of rigorous quality inspections such as:

- Automated Optical Inspection (AOI): Detects surface defects and assembly errors.

- In-Circuit Testing (ICT): Verifies electrical connectivity and function of individual components.

- Functional Testing: Confirms overall device operation under real-world conditions.

- Compliance with standards like ISO 9001 to ensure consistent process quality.

Such measures help maintain product reliability and minimize returns.

4. What files are required to submit for turnkey PCB assembly?

Commonly required design files include:

- Bill of Materials (BoM): Detailed list of components with manufacturer and part numbers.

- Gerber Files: PCB layer data showing copper traces, solder mask, silkscreen, drill holes.

- Centroid/ Pick-and-Place File: Component coordinates, orientation, and package types.

- Product Specifications: Mechanical drawings, packaging, and shipping instructions.

Providing clean, accurate files speeds quoting and production.

5. How scalable are full turnkey PCB assembly services for startups?

Turnkey providers offer flexibility to scale from low-volume prototypes to mass production. They typically support:

- Quick-turn prototype runs (10–100 pcs)

- Medium batch (hundreds to thousands)

- Large volume manufacturing with supply chain efficiency

This scalability ensures startups optimize costs and responsiveness at every growth stage.

Hot News

Hot News