What Is Copper Clad Laminate (CCL)?

Copper Clad Laminate (CCL) is the fundamental substrate material used in the fabrication of nearly all modern printed circuit boards (PCBs). In simplest terms, a CCL is a non-conductive base—typically made from fiberglass cloth, paper, or specialized polymers—impregnated with resin and clad (or bonded) on one or both sides with a thin layer of highly pure copper foil. The copper layer serves as the conductive trace material in PCB manufacturing, while the underlying substrate provides mechanical support, electrical insulation, thermal dissipation, and chemical resistance.

The Role of CCL in PCB Manufacturing

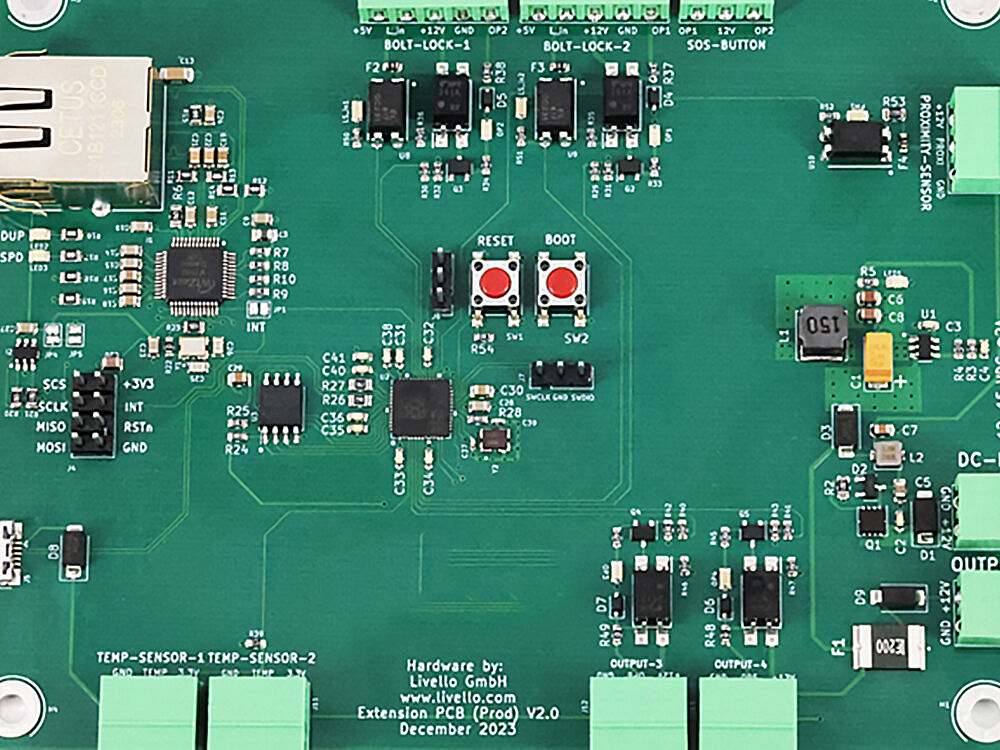

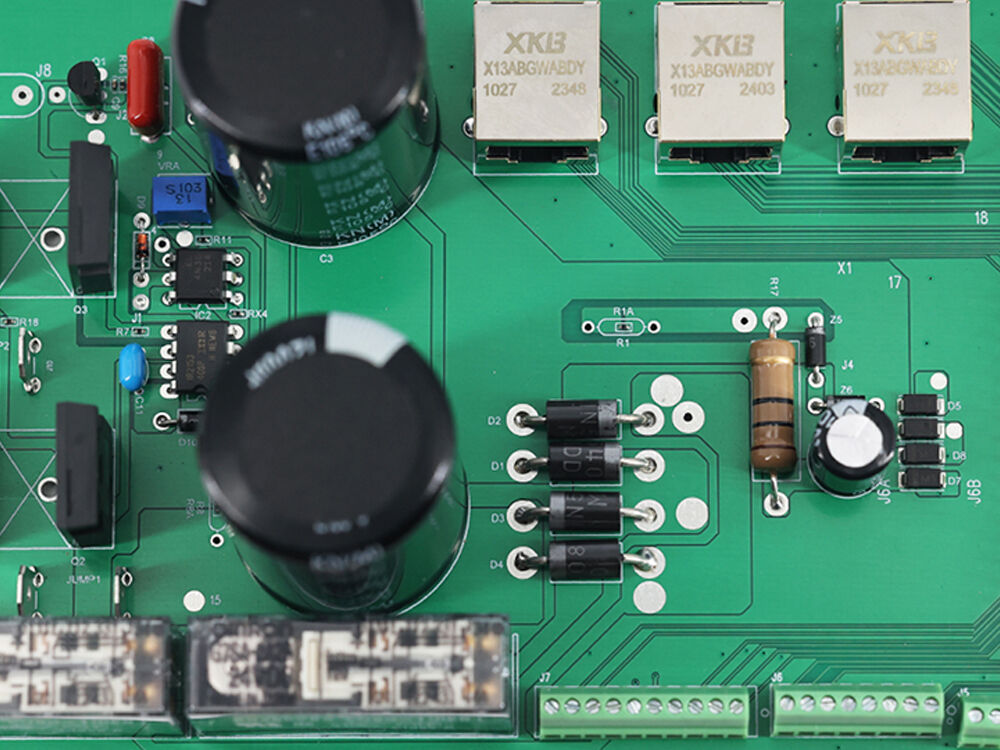

During the PCB fabrication process, the copper-clad board undergoes patterning, etching, drilling, and lamination to create the complex network of signal paths, ground planes, and power distribution “roads” that drive modern electronics. The combination of robust base materials and pure copper results in PCBs that are reliable, durable, and optimized for both mechanical stability and electrical conductivity.

Today’s demand for ever smaller, lighter, and more powerful devices places increasing emphasis on the development of advanced Copper Clad Laminates. These laminates must handle challenging requirements, such as:

- Efficient heat dissipation for power-dense or high-frequency PCBs

- High mechanical strength for industrial, automotive, or aerospace use

- Excellent electrical properties (low dielectric constant, high insulation resistance, low signal loss over distance)

- Chemical and environmental resistance for challenging operational environments

- Flame resistance and dimensional stability for safety-critical or multi-layer PCB applications

The Basic Construction of CCL

A typical Copper Clad Laminate used in PCB assembly consists of:

- Copper Foil: A thin sheet (generally 18–70 µm) of high-purity copper, electrodeposited or rolled-annealed, providing a highly conductive surface for circuit patterns.

- Dielectric/Base Material: This is usually woven electronic glass fiber impregnated with resins like epoxy, phenolic, or polyimide. In lower-cost or flexible PCBs, paper or specialty plastics may be used.

- Prepreg: “Pre-impregnated” glass fiber cloth with partially cured resin, used in multilayer PCB stackups to bond layers and provide additional electrical insulation.

Diagram: CCL Layer Structure (Pseudo-table for markdown):

|

Layer

|

Function

|

Material Options

|

|

Copper Foil

|

Signal/power circuit paths

|

ED Copper, RA Copper, VLP, etc.

|

|

Dielectric Core

|

Electrical insulation & support

|

Fiberglass/Epoxy (FR-4), Polyimide, Paper, Ceramic

|

|

Prepreg

|

Bonding, insulation in multilayers

|

Glass Fiber + Epoxy/Resin

|

Why CCL Matters – Electrical & Mechanical Backbone

The quality and composition of the Copper Clad Laminate are the primary determinants of a PCB’s performance. For instance, the dielectric constant (Dk) and dissipation factor (Df) directly affect the speed and integrity of signal propagation—crucial for high-frequency and high-speed boards. Thermal conductivity and coefficient of thermal expansion (CTE) are vital for applications exposed to rapid thermal cycling or requiring robust heat dissipation, such as automotive, RF, or power electronics.

Fact Box: Key Copper Clad Laminate (CCL) Features

- Forms the mechanical framework for PCBs of all types (rigid, flexible, rigid-flex)

- Conducts and distributes heat away from power-dense components or traces (thermal clad options)

- Available in a vast range of thicknesses, grades, and dielectric/resin types (FR-4, FR-5, CEM-1, metal-base, ceramic-base)

- Core to achieving advanced mechanical integrity, electrical insulation, and high-density electronics by enabling finer circuit fabrication and multilayer PCB constructions

In summary, Copper Clad Laminate is the invisible hero of PCB manufacturing, enabling the mass production, reliability, and miniaturization of today’s multi-functional electronic devices.

How Are CCLs Classified? A Comprehensive Guide to Commerce Control List Categories

Meta Description: Discover how Commerce Control Lists (CCLs) are classified, the key CCL categories, and what they mean for export controls and compliance in international trade.

Introduction: Understanding CCL Classification

If you’re involved in international trade or exporting technology, you’ve probably heard of Commerce Control Lists (CCLs). But how are CCLs classified, and why does it matter for your business? In this guide, we’ll break down the CCL classification system, explain the main CCL categories, and help you ensure compliance with export laws.

What is a Commerce Control List (CCL)?

The Commerce Control List (CCL) is a key component of the U.S. Department of Commerce’s Export Administration Regulations (EAR). The CCL details specific items subject to U.S. export controls, including both commercial and dual-use goods, software, and technology. Proper CCL classification determines licensing requirements and helps prevent unauthorized exports.

How Are CCLs Classified?

CCL Structure Overview

CCLs are classified using a standardized structure called the Export Control Classification Number (ECCN). The ECCN is a five-character alphanumeric code that establishes the specific controls for an item or technology.

What Is an ECCN?

-

ECCN Example: 3A001

- First Character: Category (e.g., 3 = Electronics)

- Second Character: Product Group (e.g., A = Systems, Equipment, and Components)

- Digits 3-5: Type of item and control information (e.g., 001 = Specially designed technology)

Main CCL Categories—The 10 CCL Categories

CCLs are divided into 10 broad categories, each grouping items by functionality or use:

|

Category

|

Description

|

|

0

|

Nuclear Materials, Facilities, and Equipment

|

|

1

|

Materials, Chemicals, Microorganisms, and Toxins

|

|

2

|

Materials Processing

|

|

3

|

Electronics

|

|

4

|

Computers

|

|

5

|

Telecommunications & Information Security

|

|

6

|

Sensors and Lasers

|

|

7

|

Navigation & Avionics

|

|

8

|

Marine

|

|

9

|

Aerospace & Propulsion

|

Tip: Your item’s technical specifications and intended use will generally indicate which category it falls into.

How to Read a CCL Classification

A typical CCL entry (ECCN) looks like 5A002:

- First digit: Category — In this case, 5 = Telecommunications & Information Security.

- Second letter: Product Group — A = Systems, Equipment, and Components.

- Numbers: Type of item — Defined per the CCL for each combination.

Why Is Proper CCL Classification Important?

- Compliance: Correct classification ensures you follow export laws.

- License Requirement: The ECCN defines when a license is needed.

- Avoidance of Fines: Incorrect classification can lead to significant penalties.

Step-By-Step: How to Classify an Item on the CCL

To classify an item, follow these steps:

- Identify Potential CCL Categories: Review product specs and match them to a category.

- Locate Possible ECCNs: Use the ECCN structure to identify the correct code.

- Check Product Group: Determine if your item is equipment, software, technology, etc.

- Consult the CCL Details: Read the entry’s technical notes and control criteria.

- Seek Expert Help: If unsure, contact your compliance officer or submit a Commodity Classification Request (CCATS) to the BIS.

What Makes an Excellent CCL?

1. High-Grade Base Material

The core material—such as FR-4 (fiberglass-reinforced epoxy), CEM-1, or polyimide—should offer high mechanical strength, flame retardance, and minimal moisture absorption to ensure electrical insulation and reliable performance.

2. Quality of Copper Foil

Excellent CCLs use pure, uniform copper foil with consistent thickness (typically between 18-70 microns). The copper should be free of pits and oxidation, ensuring reliable conductivity and ease of etching during manufacturing.

3. Strong Adhesion and Lamination

A superior copper clad laminate exhibits strong adhesive strength between the copper foil and the substrate. Poor adhesion can lead to delamination, reducing the PCB’s lifespan and reliability, especially in high-stress applications.

4. Dimensional Stability

An excellent CCL should maintain its size and shape under heat and stress, with minimal warping, shrinking, or splitting. Dimensional stability is crucial for precise PCB fabrication, especially for multilayer boards.

5. Electrical and Thermal Performance

Top-grade laminates offer high insulation resistance, stable dielectric constant, low dielectric loss, and robust thermal conductivity. This ensures signal integrity, minimized interference, and efficient heat dissipation in high-density circuits.

6. Surface Smoothness and Cleanliness

A flawless, clean surface allows for accurate circuit patterning and strong solder adhesion. The laminate should be free from scratches, pinholes, dust, or contamination.

Industry Standards for Copper Clad Laminate

Look for CCLs that comply with international standards such as IPC-4101, UL 94 V-0 (flame retardancy), and RoHS (environmental safety). These certifications indicate rigorous quality control and suitability for demanding electronic applications.

Factors to Consider When Choosing a CCL

- End-use environment: High-frequency or high-power PCBs require specialized laminates.

- Thickness and weight: Match the requirements of your circuit design.

- Thermal reliability: Needed for automotive, industrial, and LED applications.

- Cost and sourcing: Balance quality with budget constraints and supplier reliability.

- Environmental compliance: Ensure materials are RoHS and REACH compliant.

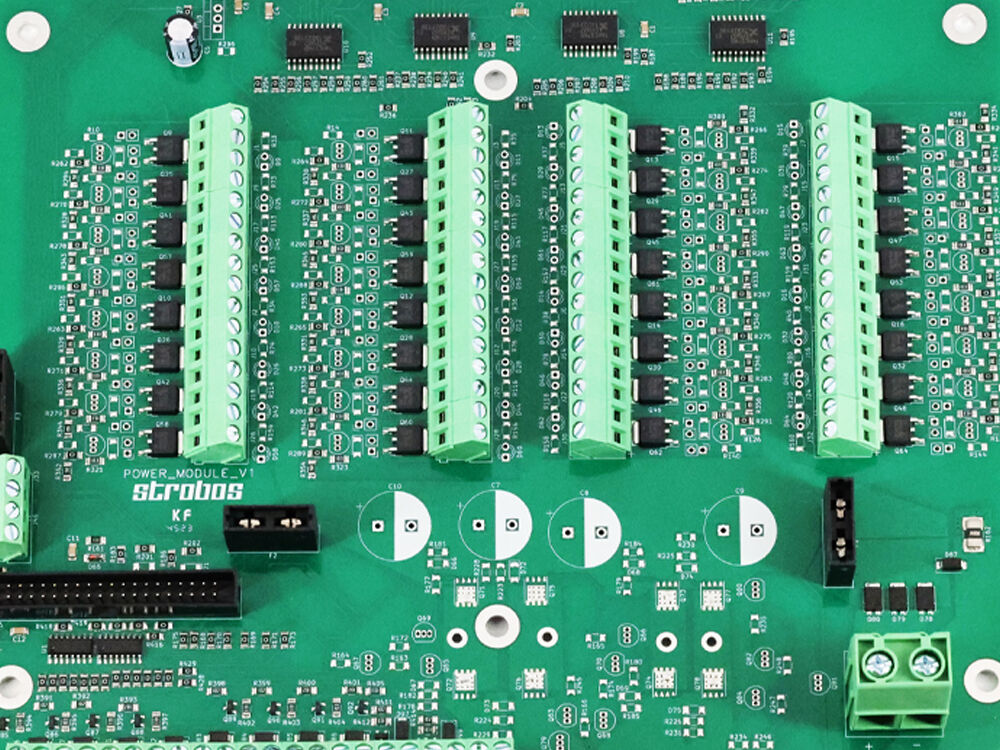

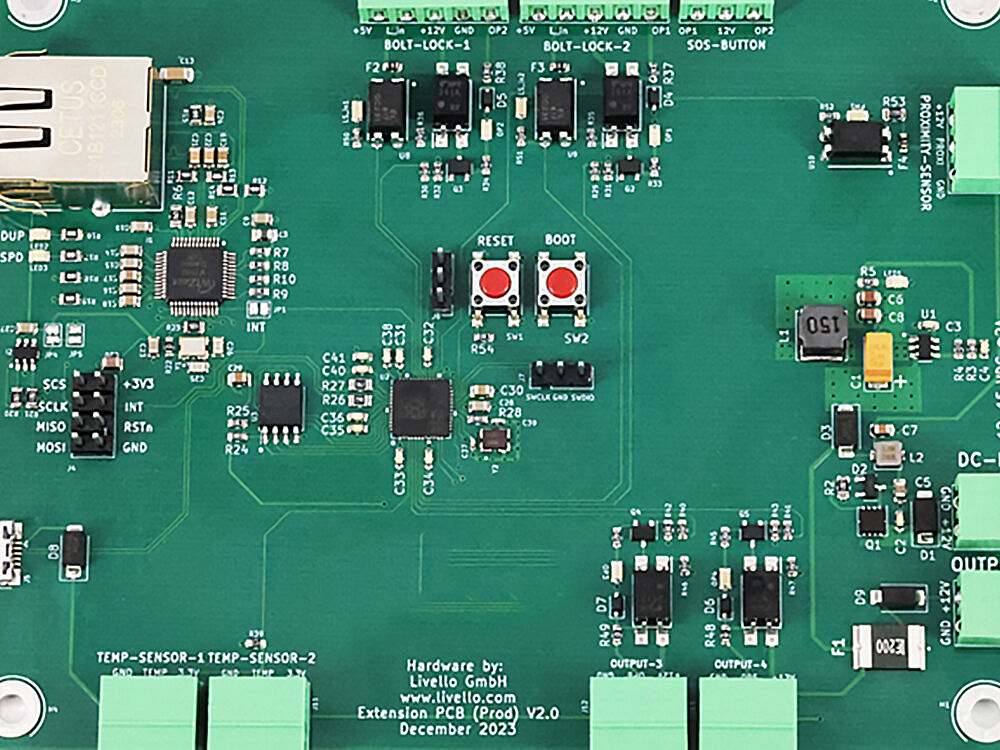

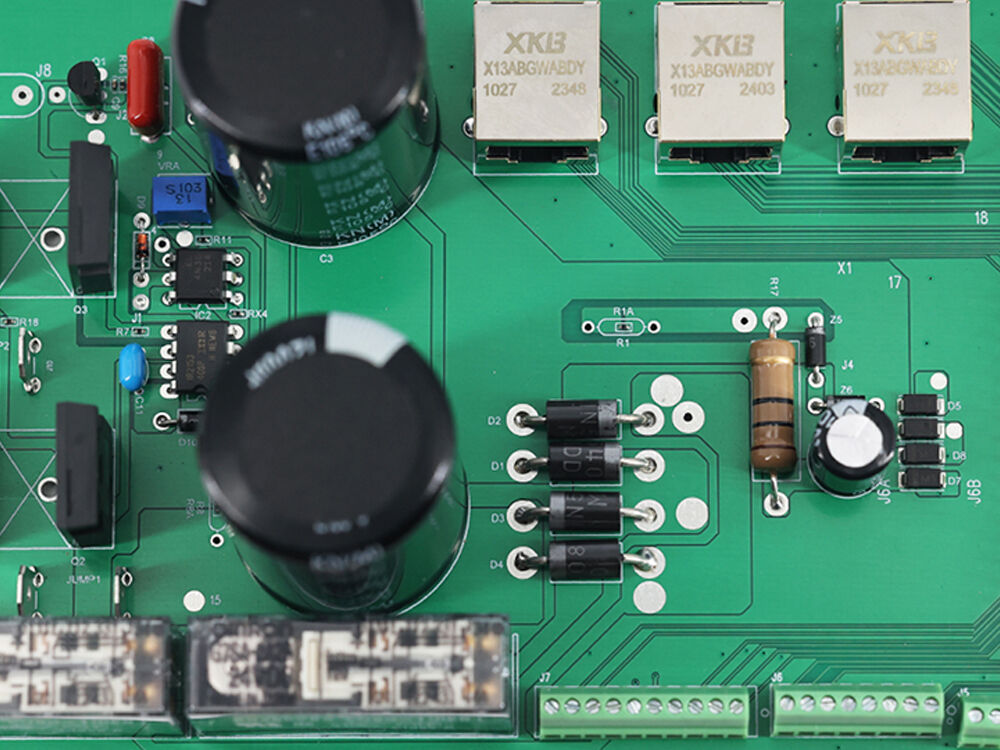

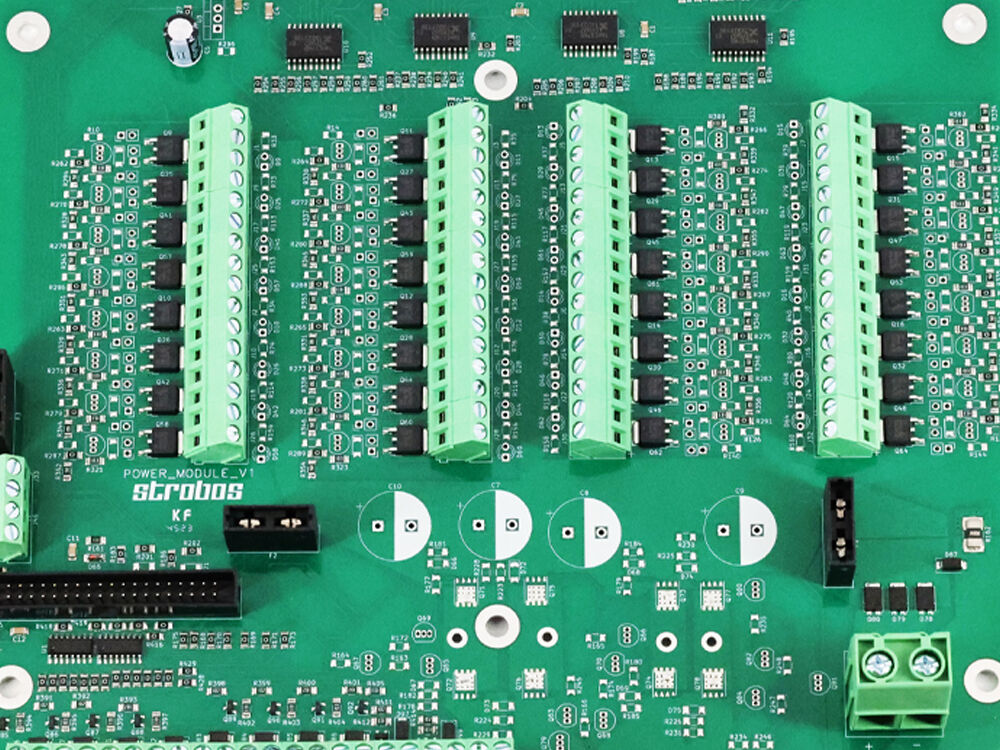

Common Applications of CCLs

- Consumer electronics (smartphones, tablets)

- Automotive electronics (engine control units, sensors)

- Industrial control systems

- Medical devices

- LED lighting

- High-frequency RF panels

Conclusion: Why Quality Matters in CCL

Choosing an excellent copper clad laminate ensures electrical stability, mechanical strength, and long-term reliability in your circuit designs. By understanding CCL specifications and focusing on key quality factors, engineers and manufacturers can produce better, more dependable PCBs that stand up to the demands of modern electronics.

Basic Structure of CCL

The basic structure of a copper clad laminate typically consists of two main components:

Insulating Substrate (Core/Base Material):

The core provides mechanical strength and electrical insulation.

Common materials:

-

-

- FR-4: Fiberglass-reinforced epoxy resin (most widely used)

- CEM-1/CEM-3: Composite epoxy materials

- Paper Phenolic: Low-cost option for simple electronics

- Polyimide, PTFE, etc.: Used in high-frequency or flexible PCBs

Copper Foil:

-

- A thin, conductive copper layer laminated onto one or both sides of the substrate.

- Standard thickness: ranges from 18 to 70 microns (µm), but may vary per application.

- The copper foil is responsible for providing the electrical pathway for electronic circuits.

(Optional Layer) - Prepreg:

- In multi-layer boards, prepreg (resin-impregnated fiberglass) is used between laminates to bond them together during lamination.

Considerations for PCB Design and Copper Clad Laminate Selection

1. Key PCB Design Considerations

a) Circuit Complexity & Layer Count

- Simple/Single-layer PCBs: Often require basic CCL (e.g., FR-4, CEM-1).

- Multi-layer & HDI PCBs: Need materials with excellent dimensional stability, low dielectric loss, and tight thickness tolerances for signal integrity.

b) Signal Integrity & Frequency

- High-speed/high-frequency circuits (RF, microwave, 5G) demand CCL with low dielectric constant (Dk) and low dissipation factor (Df) to reduce signal loss and interference.

- For analog, digital, or power PCBs, match substrate properties to signal characteristics.

c) Thermal Management

- Consider CCLs with high thermal conductivity (e.g., metal core, ceramics) for power electronics and LEDs.

- Review glass transition temperature (Tg) and decomposition temperature (Td) for operation in harsh environments.

d) Mechanical Strength & Flexibility

- Devices exposed to vibration, bending, or physical stress may use polyimide or flexible CCLs.

- Consumer/industrial boards often use rigid FR-4 for balance of strength and cost.

e) Environmental Resistance

- For automotive, aerospace, or outdoor applications, select CCL with high moisture resistance, flame retardance (e.g., UL 94 V-0), and chemical stability.

2. Critical Factors in Copper Clad Laminate Selection

a) Electrical Properties

- Dielectric Constant (Dk): Affects signal speed; lower is better for high-frequency/RF.

- Dissipation Factor (Df): Lower values reduce power loss and signal distortion.

- Insulation Resistance: Critical for preventing short circuits and crosstalk.

b) Thermal Properties

- Glass Transition Temperature (Tg): Higher Tg ensures stability at elevated operating temperatures.

- Thermal Conductivity: Essential for heat dissipation in power or LED boards.

- Coefficient of Thermal Expansion (CTE): Should match that of components to prevent mechanical failure.

c) Copper Foil Type & Thickness

- Standard thicknesses: 18, 35, or 70 μm (1/2, 1, or 2 oz/ft²).

- Type: Rolled-annealed (RA) for flex, or electrodeposited (ED) for standard applications.

- Thicker copper layers are better for high-current or power circuits.

d) Manufacturing Constraints

- Processing Compatibility: Ensure CCL works with chosen soldering and fabrication methods.

- Surface Finish: Matte or shiny, affecting adhesion and etching quality.

- Availability and Cost: Balance premium properties with budget and supplier reliability.

3. Application-Specific Recommendations

|

Application

|

Suggested CCL Type

|

Key Feature Needed

|

|

High-frequency RF

|

PTFE, Polyimide

|

Low Dk, Low Df

|

|

Power Electronics

|

Metal-core, Thick-copper

|

High thermal conductivity, thick copper

|

|

Consumer Electronics

|

Standard FR-4

|

Balance of cost, mechanical/electrical

|

|

Automotive

|

High-Tg, Halogen-free

|

Reliability in harsh environments

|

|

Flexible Circuits

|

Polyimide, PET

|

Flexibility, tear resistance

|

How do I choose the right copper clad laminate?

1. Identify Your Application and Requirements

- Circuit type: Is it analog, digital, high-speed, or RF/microwave?

- Operating environment: Will the PCB face high temperatures, moisture, vibration, or chemical exposure?

- Mechanical needs: Does the board need to be flexible or rigid?

2. Consider the Electrical Properties

-

Dielectric constant (Dk):

- Low Dk is essential for high-frequency & RF circuits (e.g., PTFE).

- Standard applications work well with FR-4.

-

Dissipation factor (Df):

- Lower values reduce power loss and signal attenuation.

-

Insulation resistance:

- Should be high to prevent leakage and short circuits.

3. Consider the Thermal Properties

-

Glass transition temperature (Tg):

- High Tg CCL is vital for boards exposed to heat or thermal cycling.

-

Thermal conductivity:

- Important for power electronics, LEDs, or any heat-generating circuits.

-

Coefficient of thermal expansion (CTE):

- Match with your components to reduce risk of failure during thermal cycling.

4. Assess Copper Foil Type and Thickness

- Standard thickness: 1 oz (35 μm) for signal, 2+ oz for power or heavy current.

- Type: Rolled-annealed (RA) for flexible circuits, electrodeposited (ED) for standard rigid PCBs.

- Uniformity: Quality CCLs will have even copper thickness and strong copper-to-base adhesion.

5. Match Mechanical and Environmental Requirements

-

Base material:

- Use FR-4 for standard/versatile applications.

- Use polyimide or PET for flex circuits.

- Metal core CCL for power/high-thermal loads.

-

Moisture/chemical resistance:

- Needed for automotive, outdoor, and industrial electronics.

-

Flame retardance:

- Look for UL 94 V-0 or similar certifications.

6. Consider Manufacturability and Cost

- Availability: Choose widely available CCL types for cost savings and ease of sourcing.

- Processing characteristics: Ensure CCL suits your soldering, drilling, and etching techniques.

- Budget: Premium, specialized materials cost more but may be necessary for high-reliability or high-frequency designs.

7. Ensure Regulatory and Environmental Compliance

- Look for RoHS and REACH compliance—especially for consumer, medical, or export products.

- Check for IPC-4101 or other relevant quality standards.

8. Consult with Your PCB Manufacturer

- Experienced manufacturers can recommend cost-effective and reliable materials based on your specs.

- Provide them with your anticipated volume, layer count, and key requirements upfront.

Quick Reference: Common Laminate Choices

|

Application

|

Recommended CCL

|

Key Feature

|

|

Standard/Consumer

|

FR-4

|

Balance of cost, performance

|

|

RF/High-Speed

|

Rogers/PTFE/Polyimide

|

Low Dk, low Df

|

|

Power/LED

|

Metal core, thick copper

|

High thermal, thick copper

|

|

Automotive/Industrial

|

High-Tg FR-4, halogen-free

|

Reliability, chemical resistance

|

|

Flexible PCBs

|

Polyimide, PET

|

Flexibility, good tear resistance

|

Properties of Copper Clad Laminates

1. Electrical Properties

Dielectric Constant (Dk): Indicates the substrate’s ability to store electrical energy. A low and stable Dk is vital for high-frequency and high-speed circuits to ensure signal accuracy and minimize losses.

Dissipation Factor (Df): Measures energy loss as heat. Lower Df ensures better signal transmission and reduced power loss, especially in RF and microwave applications.

Insulation Resistance: High insulation resistance prevents leakage currents and unintended short circuits between circuit traces.

Volume and Surface Resistivity: High resistivity values are crucial for signal integrity and preventing unwanted current paths across the PCB.

2. Thermal Properties

Glass Transition Temperature (Tg): The temperature at which the material changes from rigid to flexible. Higher Tg means better stability under heat, needed for lead-free soldering and high-temp use.

Decomposition Temperature (Td): The temperature at which the CCL chemically degrades. A high Td is required for harsh environmental conditions.

Thermal Conductivity: Determines how well the laminate dissipates heat. Important for power electronics and LED applications.

Coefficient of Thermal Expansion (CTE): Describes material expansion with temperature. Ideally, CTE should closely match that of mounted components to prevent mechanical failure.

3. Mechanical Properties

Flexural Strength: The ability to withstand bending or flexing during manufacturing and use without cracking.

Tensile Strength: Resistance to being pulled apart. Important for durability during assembly.

Dimensional Stability: Represents how well the CCL retains size/shape during temperature or humidity changes—crucial for tight-tolerance designs.

4. Chemical and Environmental Properties

Moisture Absorption: Low water uptake is preferred to avoid dielectric property changes and corrosion.

Flame Retardancy: Certified by standards such as UL 94 V-0, flame retardant CCLs enhance safety in finished devices.

Chemical Resistance: The ability to resist solvents, acids, or alkalis used during PCB processing or in the end-use environment.

Environmental Compliance: CCLs should be RoHS and REACH compliant for safe use in modern electronics.

5. Physical Properties

Copper Foil Adhesion Strength: Indicates how firmly the copper is bonded to the substrate—a key for manufacturing and long-term reliability.

Surface Smoothness: A smoother surface allows better etching quality and finer circuit patterns.

Thickness Uniformity: Consistent laminate and copper thickness are critical for multilayer PCB fabrication.

Types of Copper Clad Laminates

1. FR-4 Copper Clad Laminate

- Material: Fiberglass-reinforced epoxy resin.

- Features: Industry standard, excellent electrical insulation, moderate cost, good flame resistance (UL 94 V-0).

- Best for: Most general-purpose rigid PCBs—including computers, consumer electronics, industrial controls.

2. CEM-1 and CEM-3 Copper Clad Laminates

- Material: Composite epoxy materials (CEM-1 uses paper core, CEM-3 uses glass fabric).

-

Features:

- CEM-1: Low cost, suitable for single-sided boards.

- CEM-3: White, smoother surface, suitable for double-sided PCBs.

- Best for: LED lighting, low-cost consumer electronics.

3. Polyimide Copper Clad Laminate

- Material: Polyimide polymer reinforced with glass fiber.

- Features: High temperature resistance, superior flexibility, excellent electrical properties.

- Best for: High-performance flexible PCBs, aerospace, automotive, and military electronics.

4. PTFE (Teflon) Copper Clad Laminate

- Material: Polytetrafluoroethylene (Teflon)-based.

- Features: Ultra-low dielectric constant (Dk), extremely low loss (Df), high-frequency stability.

- Best for: RF/microwave, 5G communication devices, satellites.

5. Flexible Copper Clad Laminate (FCCL)

- Material: Polyimide or polyester base with copper foil.

- Features: Can bend and flex, thin and lightweight, excellent for dynamic applications.

- Best for: Mobile devices, laptop hinges, wearable electronics, flexible circuits.

6. Metal Core Copper Clad Laminate (MCPCB)

- Material: Aluminum or copper metal core (with dielectric layer and copper foil).

- Features: Superior heat dissipation, high mechanical strength, ideal for thermal management.

- Best for: Power electronics, LED lighting, automotive, high-power industrial PCs.

7. Paper Phenolic Copper Clad Laminate

- Material: Paper impregnated with phenolic resin.

- Features: Low cost, easy processing, moderate electrical properties.

- Best for: Low-end, single-sided consumer PCBs (e.g., toys, appliances).

8. Halogen-Free and High-Tg Laminates

- Material: Specialized epoxy/glass or polyimide compounds, without halogen flame retardants.

- Features: Eco-friendly, improved reliability, high glass transition temperature (Tg).

- Best for: Green electronics, high-reliability applications, automotive, and industrial controls.

Quick Reference Table

|

Type

|

Base Material

|

Key Features

|

Common Applications

|

|

FR-4

|

Fiberglass/Epoxy

|

Standard, flame-resistant

|

Universal PCBs

|

|

CEM-1/CEM-3

|

Paper/Glass-Epoxy

|

Cost-effective

|

LED, consumer electronics

|

|

Polyimide

|

Polyimide/Glass

|

High-temp, flexibility

|

Aerospace, flex PCBs

|

|

PTFE (Teflon)

|

PTFE

|

RF, low-loss

|

RF, 5G, microwave

|

|

Metal Core (MCPCB)

|

Aluminum/Copper

|

Heat dissipation

|

Power, LEDs, automotive

|

|

Flexible (FCCL)

|

Polyimide/Polyester

|

Bendable, thin

|

Flex circuits, wearables

|

|

Paper Phenolic

|

Paper/Phenolic

|

Cheap, easy to process

|

Simple consumer PCBs

|

|

Halogen-Free/High Tg

|

Glass Epoxy/Polyimide

|

Green, high-reliability

|

Industrial, auto

|

Is Copper Clad Better Than Copper?

Comparison Table: Copper Clad vs. Pure Copper

|

Feature

|

Copper Clad

|

Pure Copper

|

|

Conductivity

|

Lower (than pure copper)

|

Highest

|

|

Weight

|

Lighter (when core is aluminum/other material)

|

Heavier

|

|

Cost

|

Less expensive (core material is cheaper)

|

More expensive

|

|

Mechanical Strength

|

Depends on substrate (aluminum is softer)

|

Good, ductile

|

|

Use in PCBs

|

Standard (for circuit pattern formation)

|

Not used, overkill

|

|

Use in Wires/Cables

|

Acceptable for budget, short runs

|

Best for performance

|

|

Corrosion Resistance

|

May be less (if core is exposed)

|

Superior

|

When is Copper Clad Better?

- PCBs: Copper clad laminates (FR-4, CEM, aluminum core) are the industry standard. They provide a practical, made-for-purpose solution that blends cost, strength, insulation, and manufacturability. Using pure copper only for PCB substrate is NOT practical.

- Wiring: Copper-clad aluminum (CCA) wire can be lighter and cheaper for non-critical applications like speaker wire, automotive wire, or short low-power runs.

- Weight/Cost Savings: If reduced weight or cost is more important than absolute conductivity, copper clad is beneficial.

When is Pure Copper Better?

- Maximum Conductivity: Used where you need the best electrical performance and lowest resistance (e.g., power transmission, RF/microwave, high-reliability PCB traces).

- Long-Term Corrosion Resistance: Preferred in harsh, corrosive, or humid conditions.

- Mechanical Strength: For applications with mechanical stress.

The Future of Copper Clad Laminate

1. Rising Demand for Advanced Electronics

The growth of 5G, IoT, electric vehicles, AI, wearable tech, and miniaturized consumer devices is driving demand for higher-performance, more reliable, and thinner CCLs. As device complexity and circuit density increase, the need for advanced CCLs with exceptional electrical, thermal, and mechanical properties intensifies.

2. Evolution of High-Frequency & High-Speed CCLs

Increased use of high-frequency (RF, microwave, mmWave) and high-speed digital circuits is requiring:

- Lower dielectric constant (Dk) and dielectric loss (Df) for signal integrity.

- Advanced PTFE, hydrocarbon, or modified epoxy laminate systems.

- Ultra-thin, highly uniform copper foils.

- Enhanced impedance control for faster, more stable data transmission.

3. Sustainability and Eco-Friendly Materials

Environmental regulations like RoHS, REACH, and halogen-free requirements are spurring development of greener, safer PCB materials. The future will see:

- Eco-friendly, halogen-free, and lead-free CCLs.

- Biodegradable or recyclable substrate components.

- Cleaner, energy-efficient manufacturing processes for reduced carbon footprint.

4. Emphasis on Thermal Management

With power electronics, LEDs, and automotive systems generating more heat, thermal management through advanced CCLs is paramount. Trends include:

- Increased use of metal core CCLs (MCPCBs) and ceramics for improved heat dissipation.

- Laminates with higher thermal conductivity and thermal stability.

- Hybrid materials for balancing thermal and electrical demands.

5. Miniaturization and Ultralightweight CCLs

As electronic devices become smaller and lighter, CCL innovations are moving towards:

- Ultra-thin laminates for miniaturized multi-layer PCBs.

- Flexible and stretchable CCLs for wearables and foldable devices.

- Advanced manufacturing (e.g., laser drilling, additive copper plating) for finer circuit features.

6. Cost Efficiency and Performance Balance

Continued pressure to reduce cost while increasing performance drives:

- Material innovation for affordable yet high-spec laminates.

- Optimization of manufacturing processes to reduce waste and energy use.

- Global supply chain diversification for stable, low-cost CCL sourcing.

7. Smart and Functional Laminates

In the coming years, CCLs could gain new functionalities:

- Embedded sensors, passive components, or shielding.

- Self-healing, self-monitoring, or adaptive properties for smart PCBs.

8. Digitalization and Industry 4.0 in CCL Manufacturing

Expect more automation, data analytics, and AI in:

- Quality control and defect detection.

- Optimized laminating and copper foiling processes.

- Mass customization to meet diverse application needs quickly.

Hot News

Hot News