Quick Turn PCB Assembly

Fast-track PCB/PCBA assembly for urgent prototypes and low-to-medium volume orders—delivering precision, compliance, and speed without compromising quality.

✅ Rapid turnaround for urgent prototypes & orders

✅ IPC-compliant precision assembly

✅ In-stock component support to cut lead times

✅ Low-to-medium volume scalability

Description

What is Quick Turn PCB Assembly?

Quick Turn PCB Assembly refers to a specialized PCB assembly service tailored for short lead time requirements. Its core lies in optimizing the supply chain, production processes, and resource allocation to complete the full assembly workflow—from bare PCB procurement, component sourcing/selection, to SMT placement, soldering, and testing—in an ultra-short timeframe. It is designed to meet the delivery needs of prototype fabrication, small-batch trial production, or urgent orders.

Core Features

· Ultra-Short Lead Times

Regular PCB assembly typically takes 7–15 days, while fast-turn services can shorten this to 24 hours, 48 hours, or 3–5 days. Some manufacturers even offer same-day expedited shipping to support R&D prototyping and emergency stock replenishment scenarios.

· Optimized for Small-Batch/Prototype Orders

The service focuses on small-batch orders ranging from 1 to 1,000 units, eliminating the need for minimum order quantities (MOQs) for mass production. This lowers cost and time barriers during the R&D and trial production phases.

· Priority Resource Allocation Throughout the Process

Components: Prioritize using in-stock inventory or collaborating with high-response component suppliers to minimize procurement lead times.

Production Lines: Reserve dedicated workstations on expedited production lines, skip non-essential scheduling procedures, and prioritize SMT placement, soldering, and testing.

Quality Control: Adopt rapid inspection solutions to streamline partial sampling processes while ensuring basic quality standards.

· Flexible Service Compatibility

Support multiple assembly processes (SMT, Through-Hole Technology (THT), mixed assembly) and accommodate PCBs of varying layer counts and sizes. It meets urgent assembly needs across industries such as consumer electronics, industrial control, and medical devices.

· Typical Applications

Product R&D Phase: Rapidly manufacture functional prototypes to verify design feasibility and shorten R&D iteration cycles.

Emergency Stock Replenishment: Address sudden spikes in end-product orders and avoid supply chain disruptions.

Small-Batch Trial Production: Produce small volumes of products for market testing or customer validation before full-scale mass production.

Benefits of Quick Turn PCB Assembly Orders

Quick turn PCB assembly delivers targeted advantages for businesses across R&D, production, and supply chain management, addressing time-sensitive demands while maintaining operational flexibility. Below are its core benefits:

Accelerates Product Development Cycles

Rapid turnaround of prototypes (as fast as 24–48 hours) allows engineers to validate design functionality, test circuit performance, and iterate modifications immediately. This cuts weeks off traditional R&D timelines, enabling faster transition from concept to market-ready products and securing first-mover advantages in competitive sectors.

Supports Agile Small-Batch Production

Eliminates minimum order quantity (MOQ) restrictions for small-batch runs (1–1,000 units). Businesses can produce trial batches for market validation, client demos, or pilot programs without committing to large-scale manufacturing. This agility is ideal for startups and enterprises testing niche product ideas or custom solutions.

Mitigates Supply Chain Disruptions

Serves as a critical contingency for urgent stock replenishment—whether to address unexpected order surges, replace defective components, or cover production line gaps caused by supplier delays. Quick turn services prevent costly downtime and revenue losses from supply chain bottlenecks.

Optimizes Cost Efficiency for Short-Term Needs

While premium-priced compared to standard assembly, it reduces hidden costs associated with prolonged lead times: e.g., avoided project delays, reduced storage fees for excess inventory, and minimized opportunity costs of missing market windows. For time-critical projects, the ROI of faster delivery far outweighs the incremental service cost.

Enhances Production Flexibility

Compatible with diverse assembly processes (SMT, THT, mixed technology) and PCB specifications (multi-layer boards, custom sizes). Manufacturers can adapt to last-minute design tweaks or specialized requirements without extensive retooling, supporting cross-industry needs from consumer electronics to medical devices.

Ensures Reliable Quality with Streamlined QC

Leverages advanced rapid testing tools (AOI, X-Ray inspection) to uphold core quality standards while optimizing inspection workflows. This balances speed and precision, reducing the risk of defective units reaching the next production stage or end-users.

How to Get Quick Turn PCBAs

Securing fast-turn PCB assemblies efficiently requires a structured, collaborative approach between you and your manufacturing partner, with clear communication and pre-prepared inputs to minimize delays. Follow these key steps:

· Clarify Your Urgency & Requirements Upfront

Define your critical lead time and confirm order specifications: PCB layer count, size, assembly type (SMT, THT, mixed), component density, and industry compliance standards. Explicitly state whether you need prototypes, small-batch production, or emergency replenishment—this helps the supplier allocate dedicated resources immediately.

· Prepare and Submit Complete Design Files

Provide error-free, industry-standard design documents to avoid rework delays:

· Gerber files for PCB fabrication (ensure they include drill files, solder mask, and silkscreen layers).

· Bill of Materials (BOM) with detailed component specs: part numbers, manufacturers, quantity, and packaging type. Highlight hard-to-source components if any.

· Pick-and-place files (Centroid files) and assembly drawings with clear notes on polarity, special soldering requirements, or test points.

· Finalize Component Sourcing Responsibilities

Choose a sourcing model that aligns with your speed needs:

Customer-Furnished Components (CFC): Deliver pre-sorted, verified components to the supplier in labeled packages. Ensure all parts are in stock and meet production standards to eliminate sourcing delays.

Supplier-Furnished Components (SFC): Select a manufacturer with a robust in-house component inventory and partnerships with authorized distributors. This reduces lead times by avoiding third-party procurement bottlenecks.

Confirm component availability before placing the order—this is the most common cause of fast-turn project delays.

· Select a Qualified Quick-Turn PCB Assembly Partner

Prioritize suppliers with these core capabilities:

· Dedicated expedited production lines and 24/7 operational capacity.

· Advanced rapid QC equipment (AOI, X-Ray, functional testing) to maintain quality without sacrificing speed.

· Proven track record of meeting tight deadlines (request case studies or customer testimonials for similar projects).

· Transparent communication channels for real-time order status updates.

· Confirm Pricing, Terms, and Quality Standards

Negotiate a clear quote that includes expedited service fees, component costs (if SFC), and testing charges. Clarify terms like payment deadlines, shipping methods, and defect resolution policies. Agree on QC checkpoints upfront—balance speed with essential quality checks to avoid post-delivery issues.

· Track Production and Receive the Finished PCBA

Stay in close contact with your supplier for real-time production updates. Upon delivery, inspect the PCBAs against your acceptance criteria: verify component placement accuracy, solder quality, and functional performance (if applicable).

The Common Challenges in Quick Turn PCB Assembly

Quick turn PCB assembly delivers ultra-short lead times but faces unique hurdles driven by compressed timelines, resource constraints, and tight coordination requirements. Below are the most prevalent challenges and their underlying causes:

Component Sourcing Delays

This is the top cause of quick turn project setbacks. High-priority orders often rely on scarce, niche, or long-lead components. Even minor shortages can derail the entire production schedule. Additionally, last-minute component verifications may be rushed, increasing the risk of using non-conforming parts. Suppliers may also struggle to source alternatives quickly if the original components are out of stock.

Design-Related Errors and Rework

Fast-paced order processing leaves little time for thorough design for manufacturability (DFM) checks. Common issues include incomplete Gerber files, incorrect pick-and-place coordinates, ambiguous polarity markings for sensitive components, or inadequate solder mask clearances. These errors are often discovered mid-production, forcing urgent rework that directly impacts turnaround times. Unlike standard orders, quick turn projects lack buffer time to resolve design flaws without delays.

Balancing Speed and Quality Control

To meet tight deadlines, some manufacturers may streamline or skip non-critical QC steps. Over-simplification can lead to missed defects such as poor solder joints, misaligned components, or hidden internal layer issues. On the other hand, maintaining rigorous QC protocols within compressed timelines requires advanced equipment and 24/7 staffing, which many suppliers cannot consistently support. This creates a difficult trade-off between speed and product reliability.

Resource Allocation Constraints

Quick turn orders demand dedicated production lines, specialized technicians, and priority access to equipment. During peak demand periods, suppliers may face capacity limits—competing urgent orders can lead to resource conflicts, resulting in delayed start times for some projects. Additionally, emergency shifts or overtime work to meet deadlines can increase labor costs and lead to human errors due to fatigue.

Communication Gaps Between Customers and Suppliers

Misaligned expectations often cause bottlenecks. For example, customers may fail to specify critical requirements or rush to submit incomplete order information. Conversely, suppliers may not proactively update customers on production hiccups. Poor communication leads to rework, order revisions, and missed delivery windows—all costly in quick turn scenarios.

Higher Cost Volatility

Quick turn services inherently carry premium pricing due to expedited labor, priority sourcing, and overtime expenses. However, costs can escalate unexpectedly: rush fees for component shipping, charges for emergency DFM fixes, or premiums for sourcing hard-to-find parts. Customers may face sticker shock if these additional costs are not clarified upfront in the quote.

Factors to Consider in Choosing a Quick Turn PCB Assembly Manufacturer

Selecting the right quick turn PCB assembly manufacturer is critical to meeting tight deadlines while maintaining product quality. Below are the key factors to evaluate to ensure a reliable, efficient partnership:

☑ Expedited Production Capability & Lead Time Track Record

· Verify the manufacturer’s core quick turn lead time range and confirm if these timelines are achievable for your order size and PCB specifications.

· Request case studies or customer testimonials for similar urgent projects—prioritize suppliers with a proven history of meeting or exceeding tight deadlines without sacrificing quality.

· Check if they have dedicated expedited production lines and 24/7 operational capacity to avoid delays caused by competing standard orders.

☑ Component Sourcing Strength

· Evaluate their component supply chain: Opt for manufacturers with in-house stock of common components and partnerships with authorized distributors for hard-to-source or niche parts.

· Confirm their ability to handle both Customer-Furnished Components and Supplier-Furnished Components. For CFC orders, check their process for fast component verification and sorting; for SFC, ensure they can source RoHS/IPC-compliant parts quickly and validate component authenticity.

· Assess their contingency plans for component shortages.

☑ Quality Control Standards for Fast-Turn Projects

· Avoid suppliers that cut corners on QC to speed up production. Look for those equipped with rapid inspection technologies: Automated Optical Inspection (AOI), X-Ray inspection , and in-circuit testing (ICT) for functional validation.

· Confirm compliance with industry standards like IPC-A-610 and check if they offer customizable QC checkpoints to align with your product’s requirements.

· Ask about their defect rate and rework process—transparent reporting on quality metrics is a sign of reliability.

☑ Design for Manufacturability Support

· Quick turn projects leave little room for design errors. Choose a manufacturer that provides free, fast DFM checks within hours of receiving your Gerber/BOM files.

· Ensure their engineering team can flag and resolve manufacturability issues proactively, with clear communication and minimal delays for revisions.

☑ Communication & Order Visibility

· Prioritize suppliers with real-time order tracking systems and dedicated account managers for urgent projects—you need timely updates on production milestones, component status, or potential bottlenecks.

· Verify their response time for inquiries and their flexibility to accommodate last-minute, minor design tweaks without derailing the timeline.

☑ Pricing Transparency & Cost Structure

· Quick turn services carry premium pricing, but avoid hidden fees. Request a detailed quote that breaks down costs: expedited service fees, component costs, testing charges, and shipping fees.

· Clarify cost adjustment policies for order changes to prevent unexpected budget overruns.

☑ Industry Compliance & Certifications

Ensure the manufacturer holds relevant certifications for your target market, such as ISO 9001, ISO 13485, UL certification, or RoHS compliance.

For specialized industries, check if they have experience with high-reliability quick turn PCBAs that meet strict regulatory standards.

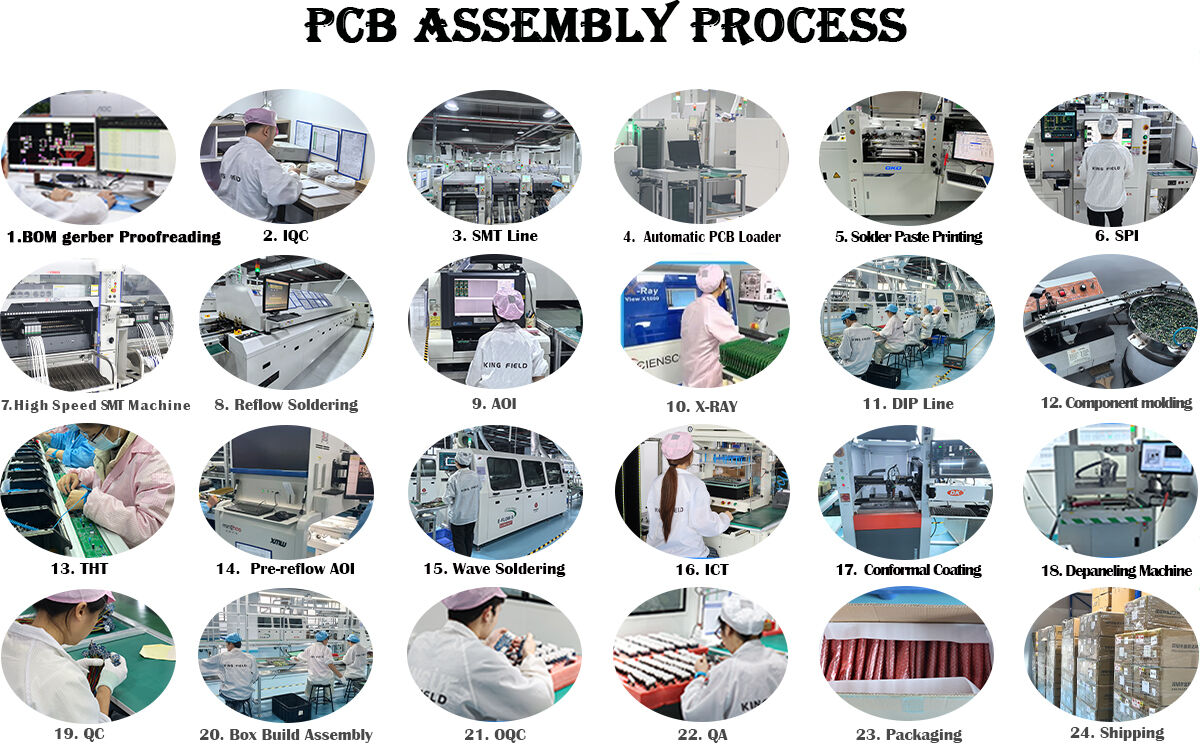

What is the Quick Turn PCB Assembly Process?

The quick turn PCB assembly process is a streamlined, priority-driven workflow designed to minimize lead times while maintaining core quality standards. Unlike standard assembly, it eliminates non-critical steps, allocates dedicated resources, and accelerates coordination between fabrication, sourcing, and testing teams. Below is the step-by-step breakdown:

☑ Order Intake & Requirement Validation

The manufacturer receives and reviews all customer inputs immediately: Gerber files, BOM (Bill of Materials), pick-and-place data, assembly drawings, and lead time targets. A dedicated engineer conducts a rapid DFM check to flag critical issues that could cause delays. Any discrepancies are resolved with the customer in real time—no back-and-forth delays are allowed for quick turn projects.

☑ Component Sourcing & Preparation

· If using Supplier-Furnished Components: The team pulls common parts from in-house stock first; hard-to-source components are ordered via priority distributor channels with expedited shipping. Components are verified for compliance (RoHS, IPC) and compatibility within hours.

· If using Customer-Furnished Components: The supplier inspects and sorts delivered parts immediately to confirm quantity, packaging, and functionality—defective or missing components are flagged to the customer at once to avoid production halts.

All components are prepared for SMT/THT assembly (e.g., tape-and-reel packaging for SMT parts) without delay.

☑Bare PCB Procurement & Pre-Assembly Prep

To save time, bare PCB fabrication runs in parallel with component sourcing. Quick turn manufacturers partner with PCB fabs that offer expedited bare board production. Upon arrival, PCBs are cleaned, inspected for surface defects, and aligned for assembly to eliminate setup delays on the production line.

☑Assembly Execution

The order is assigned to a reserved expedited production line to skip standard production queues. The assembly process follows these steps based on technology:

· SMT Assembly: Solder paste is applied via stencil printing → components are placed by high-speed pick-and-place machines → boards go through reflow soldering → automated optical inspection (AOI) checks for placement/solder defects.

· THT Assembly: Through-hole components are inserted (manual or automated) → wave soldering or selective soldering is performed → post-solder trimming of leads.

· Mixed Technology: SMT steps are completed first, followed by THT assembly, with minimal wait time between stages.

☑Rapid Quality Control & Testing

QC is optimized for speed without compromising essential checks:

AOI & X-Ray Inspection: AOI scans surface-mounted components; X-Ray is used for hidden joints to detect voids or misalignment—both tests run inline to avoid batch delays.

Functional Testing: For high-priority products, a simplified functional test is conducted to verify core performance. Custom test procedures are pre-approved by the customer to prevent scope creep.

Compliance Check: A final audit ensures adherence to industry standards and customer-specific requirements.

☑Packaging & Expedited Shipping

Passed PCBAs are packaged in anti-static materials to prevent damage. The manufacturer coordinates expedited shipping per the customer’s request. A detailed shipping confirmation with tracking info is sent immediately, and the order is marked as complete.

☑Key Differentiator from Standard Assembly

The entire workflow is non-linear and parallelized instead of sequential. Dedicated teams, reserved equipment, and real-time communication eliminate all unnecessary wait times.

Production Capacity

| Assembly Types |

● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

||||

| Quality Inspection |

● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

||||

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB | ||||

| Component Types |

● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

||||

| Components Sourcing |

● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

||||

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste | ||||

| Order quantity |

● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

||||

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready | ||||