Selecting the right PCB material is critical for the performance, reliability, and cost of your electronic project. FR4 PCB material is the most widely used substrate in the printed circuit board industry. In this comprehensive guide, we’ll examine why FR4 is the standard, its key properties, benefits, and limitations, tips for selecting the right FR4 material, and how it compares with other PCB material choices.

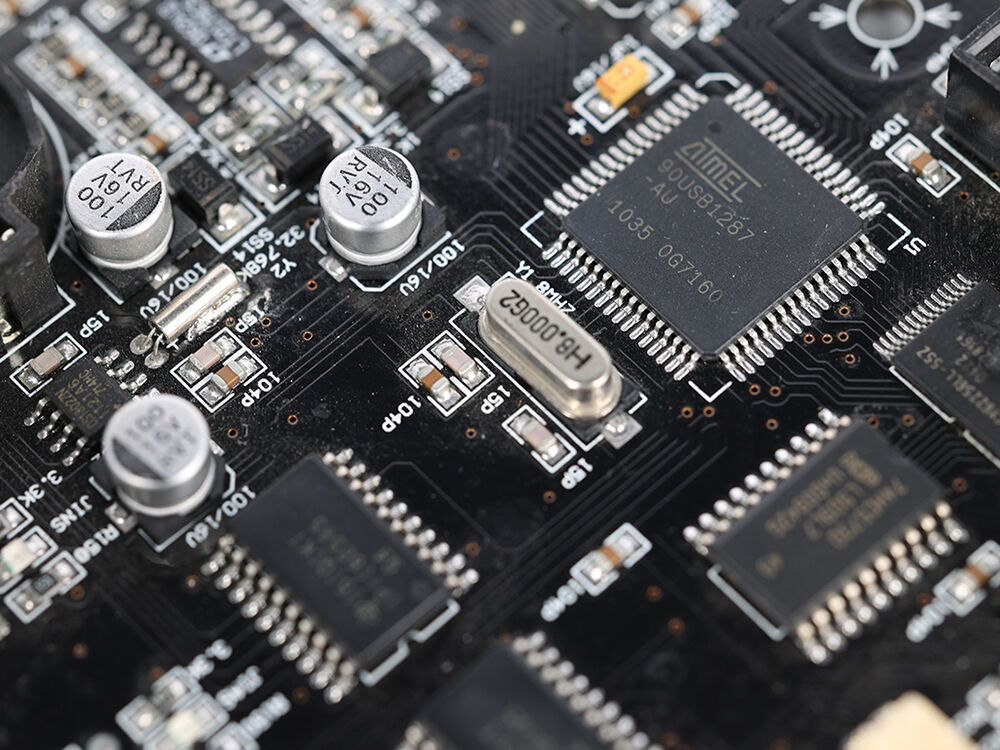

FR4 stands for Flame Retardant 4, a glass fiber–reinforced epoxy laminate. This composite structure gives FR4 exceptional mechanical strength, good electrical insulation, and crucial flame resistance, making it the default choice for PCB fabrication.

FR4 stands for "Flame Retardant 4," and it refers to a specific grade of glass-reinforced epoxy laminate material that is used as the base for PCBs. The “FR” signifies its flame-retardant capabilities, crucial for electronic safety compliance, while the “4” is a designation among various flame-retardant materials (like FR1, FR2, FR3, and FR5).

FR4 is engineered from woven fiberglass cloth bonded with a high glass transition epoxy resin. This composite construction creates a mechanically robust, electrically insulating, and flame-resistant material—making it ideal as the backbone for a wide range of PCB applications, from single-layer prototypes to complex multi-layer high-speed designs.

Key Points:

|

Property |

Isola FR4 |

Nelco FR4 |

Ventec FR4 |

|

TG (°C) |

135–180 |

140–185 |

140–170 |

|

Dk (1MHz) |

4.5 |

4.2–4.8 |

4.4–4.7 |

|

Moisture Absorption (%) |

0.15 |

0.18 |

0.20 |

|

Material |

Uses |

Limitation |

|

FR1 |

Early radios |

Paper/phenolic, low TG |

|

FR2 |

Simple aerospace circuits |

Cotton/phenolic, low TG |

|

FR3 |

Older electronics |

Moderate TG |

|

FR4 |

All mainstream PCBs |

Good all-around |

|

FR5 |

Aerospace/military |

High TG, high cost |

IMS vs FR4: IMS (Insulated Metal Substrate) PCBs use metal base for heat dissipation, while FR4 is best for signal integrity and general-purpose use.

Factors to Consider:

IPC-A-600 sets quality standards for FR4 PCB materials, covering:

Whether you’re a design engineer or a decision-maker in electronics procurement, understanding FR4 material properties helps in:

Let’s break down what makes FR4 material so effective and versatile:

Together, these components create a substrate with superb electrical properties, low moisture absorption, and strong flame retardance.

|

Layer |

Function & Relevance |

|

Fiberglass |

Mechanical strength, stability |

|

Epoxy Resin |

Electrical insulation, flame retardance |

|

Copper Foil* |

Conductive layers for circuit traces |

|

Solder Mask* |

Protective, insulative layer (optional) |

*Note: Copper foil and solder mask are part of the whole PCB manufacturing process, not the FR4 sheet itself, but they interact closely with FR4’s properties.

|

Property |

Typical Value / Range |

|

Flame Retardancy |

UL94 V-0 |

|

Dielectric Constant(Dk) |

4.2–4.8 (at 1 MHz) |

|

Dissipation Factor (Df) |

~0.02 |

|

Water Absorption |

<0.2% |

|

Tensile Strength |

40,000–65,000 psi |

|

Glass Transition (Tg) |

130–200°C (dependent on grade) |

|

Moisture Resistance |

High (minimal property loss) |

FR4 PCB substrate is pivotal not only for consumer electronics but also for industrial, automotive, military, and aerospace PCBs. Its balanced material properties allow for the integration of through-hole components, edge connectors, solder mask applications, multi-layer PCB architectures, and more.

Quote: “Without the innovation of flame-retardant glass-reinforced epoxy like FR4, the reliability and accessibility of modern electronics would simply not be possible.” — Senior Materials Scientist, Global PCB Manufacturer

FR4 PCB thickness directly affects several aspects of PCB reliability and function:

While custom thicknesses are possible, standard sizes help streamline the PCB manufacturing process and ensure compatibility with common assembly and design practices. Here’s a quick reference:

|

FR4 Thickness (mm) |

FR4 Thickness (inches) |

Common Applications |

|

0.2 – 0.3 |

0.008 – 0.012 |

Flexible, ultra-thin, space-limited |

|

0.4 – 0.6 |

0.016 – 0.024 |

Compact consumer, wearables |

|

0.8 – 1.0 |

0.032 – 0.040 |

Lightweight, portable electronics |

|

1.2 – 1.6 |

0.047 – 0.063 |

Standard industrial, consumer PCBs |

|

2.0 – 3.2 |

0.079 – 0.126 |

Rugged, power, large connectors |

Fun fact: The most common industry standard thickness for an FR4 PCB is 1.6 mm (0.063 inch)—a perfect blend of durability, manufacturability, and compatibility for most component and edge connector profiles.

Here are the most important factors to evaluate when deciding on FR4 material thickness for your printed circuit board design:

|

PCB Application |

Recommended FR4 Thickness |

Notes |

|

Ultra-compact electronics |

0.2 – 0.6 mm |

Wearables, medical sensors, thin IoT boards |

|

Consumer electronics |

0.8 – 1.2 mm |

Phones, tablets, home devices |

|

General industrial |

1.6 mm (standard) |

Reliable default, most connectors fit |

|

Power/automotive |

2.0 – 3.2 mm |

Power regulators, control units |

|

Special RF/microwave |

Application-specific |

Tuned for impedance and propagation |

Choosing the right substrate is foundational to any successful printed circuit board (PCB) design, and FR4 material stands apart as the industry standard for exceptional reasons. Whether you’re constructing a basic consumer device, a multilayer control system for industrial machinery, or the next innovation in the IoT space, FR4 offers a set of properties that reliably align with stringent electrical, thermal, and mechanical demands—at a price point accessible to both large manufacturers and small prototyping shops.

|

Benefit |

FR4 Feature |

|

Electrical Insulation |

High dielectric strength, dielectric constant (Dk) 4.2-4.8 |

|

Flame Retardance |

Meets UL94-V0 safety standard |

|

Mechanical Strength |

Woven fiberglass + epoxy for rigidity and durability |

|

Moisture Resistance |

Absorbs <0.2% water, stable in humidity |

|

Temperature Resistance |

Tg up to 200°C, stable during reflow and operation |

|

Cost-Effectiveness |

Low material and manufacturing costs |

|

Manufacturing Flexibility |

Supports multilayer, flexible, rigid PCBs |

|

Industry Versatility |

Used in consumer, industrial, automotive, aerospace, etc. |

|

Industry |

Application |

Reason for FR4 Use |

|

Consumer Electronics |

Phones, Wearables, Home Devices |

Cost, size, manufacturability |

|

Industrial |

Robot Controllers, Sensors, PLCs |

Strength, heat/flame resistance |

|

Automotive |

ECUs, Lighting, ADAS Modules |

Ruggedness, reliability, cost |

|

LEDs & Lighting |

Strips, Panels, Modular Lighting |

Thermal stability, electrical insulation |

|

Medical |

Monitors, Sensors, Diagnostics |

Insulation, stability, compliance |

|

Communications |

Routers, Modems, Antennas |

Signal integrity, impedance stability |

|

Education/Research |

Prototypes, Test Boards |

Affordability, ease of design |

When designing high-performance printed circuit boards, the choice of substrate material is crucial. Rogers and FR4 are two of the most common PCB materials—but when do you choose Rogers, and why is Rogers often considered better than FR4, especially for advanced applications?

|

Feature |

Rogers Material |

FR4 Material |

|

Dielectric Constant (Dk) |

Consistent, low Dk (ideal for high-frequency) |

Higher, less stable |

|

Loss Tangent |

Very low (minimal signal loss) |

Higher (more signal loss) |

|

Frequency Support |

Excellent for RF/microwave |

Limited to lower MHz/GHz |

|

Thermal Stability |

Superior (minimal shift in heat) |

Lower heat stability |

|

Cost |

More expensive |

Economical |

1. Superior High-Frequency Performance Rogers PCBs have a much lower and more stable dielectric constant, which ensures minimal signal loss and distortion—even at high frequencies. This is vital for applications such as RF, microwave, 5G, and aerospace.

2. Lower Signal Loss (Low Dissipation Factor) Thanks to their low loss tangent, Rogers laminates allow cleaner and faster signal transmission. FR4, on the other hand, tends to absorb more signal, resulting in greater loss—especially as frequencies increase.

3. Exceptional Thermal Management Rogers materials withstand higher temperatures and offer better thermal stability than FR4, making them reliable for demanding environments (e.g., automotive radar, satellite communications).

4. Consistent Electrical Properties Rogers provides uniform signal behavior across the board, which is critical in precision designs. FR4’s electrical properties can vary with temperature and frequency.

Hot News

Hot News2026-01-17

2026-01-16

2026-01-15

2026-01-14

2026-01-13

2026-01-12

2026-01-09

2026-01-08