Learn what a PCBA is, how it differs from a PCB, the assembly process, components, applications, industry services, and essential FAQs. Covers everything about printed circuit board assembly for engineers, hobbyists, and manufacturers.

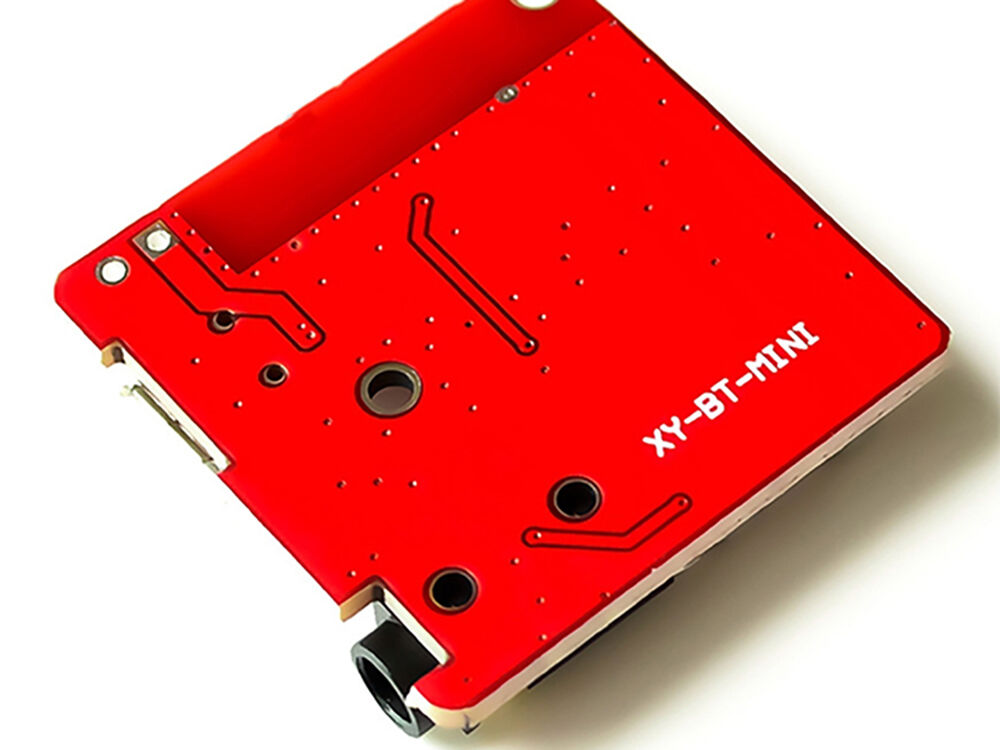

In today’s electronic-driven world, understanding PCBA (Printed Circuit Board Assembly) and PCB (Printed Circuit Board) is essential for anyone involved with modern technology. A PCB is the base platform that supports and connects electronic components, while a PCBA is the fully assembled board with all components mounted and soldered, ready to power a device.

PCBs and PCBAs form the backbone of every modern electronic device—from smartphones and laptops to medical equipment and automotive systems. Their design and assembly directly determine a product’s performance, durability, and functionality. By mastering the basics of PCB and PCBA, you gain insights into how everyday electronics work and what makes them reliable and efficient.

Whether you’re a product designer, engineer, manufacturer, or simply an electronics enthusiast, learning about these foundational processes empowers you to create, troubleshoot, or innovate with confidence in the fast-evolving electronics industry.

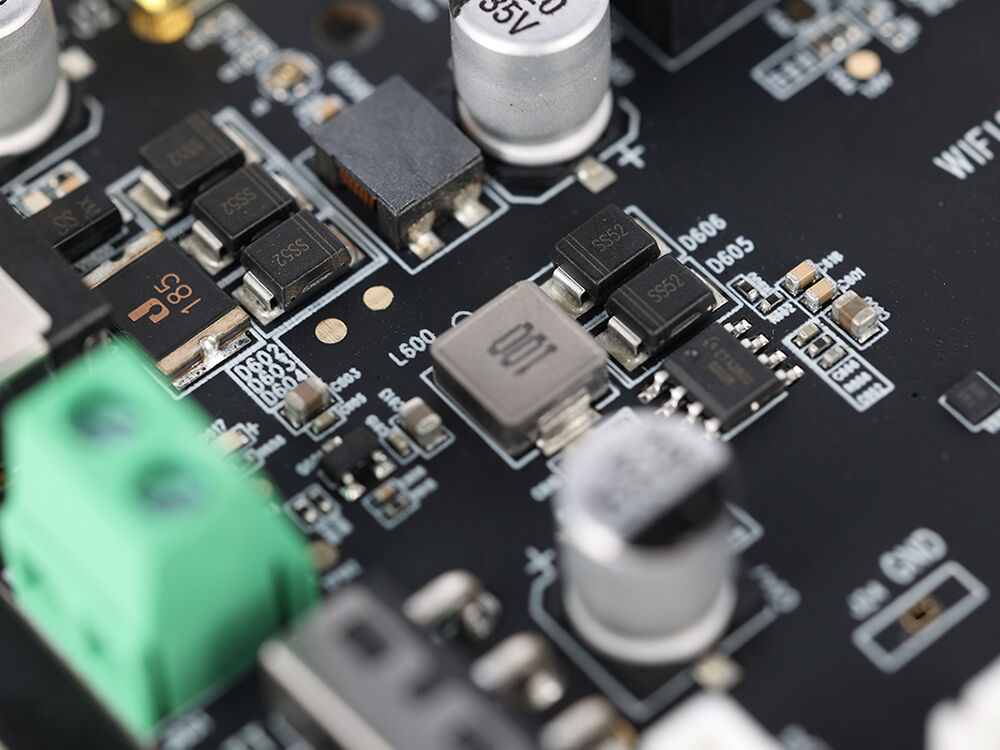

A PCB, or Printed Circuit Board, is a flat, rigid board that provides both the physical foundation and the electrical connections needed to support and integrate electronic components within a device. Typically made from layers of fiberglass or other insulating material, a PCB features thin copper traces etched onto its surface to form the pathways that connect various components, such as resistors, capacitors, and integrated circuits.

Printed circuit boards are designed to organize and secure these components in a compact, efficient layout, ensuring reliable signal transmission and minimizing electrical interference. The development of PCBs has transformed the electronics industry by allowing for compact, complex, and mass-producible products—from smartphones and computers to automotive sensors and home appliances.

In summary, a PCB is the essential building block for nearly all modern electronic devices, forming the backbone of how their components communicate and function together.

When exploring types of PCBs (Printed Circuit Boards), it’s important to understand that differences in layer count, substrate materials, and flexibility play a crucial role in how the board functions within electronic devices. Here are the main types of PCBs used in the electronics industry:

1. Single-Sided PCB

2. Double-Sided PCB

3. Multi-Layer PCB

4. Rigid PCB

5. Flexible PCB (Flex PCB)

6. Rigid-Flex PCB

7. High-Frequency PCB

8. Aluminum-Backed (Metal Core) PCB

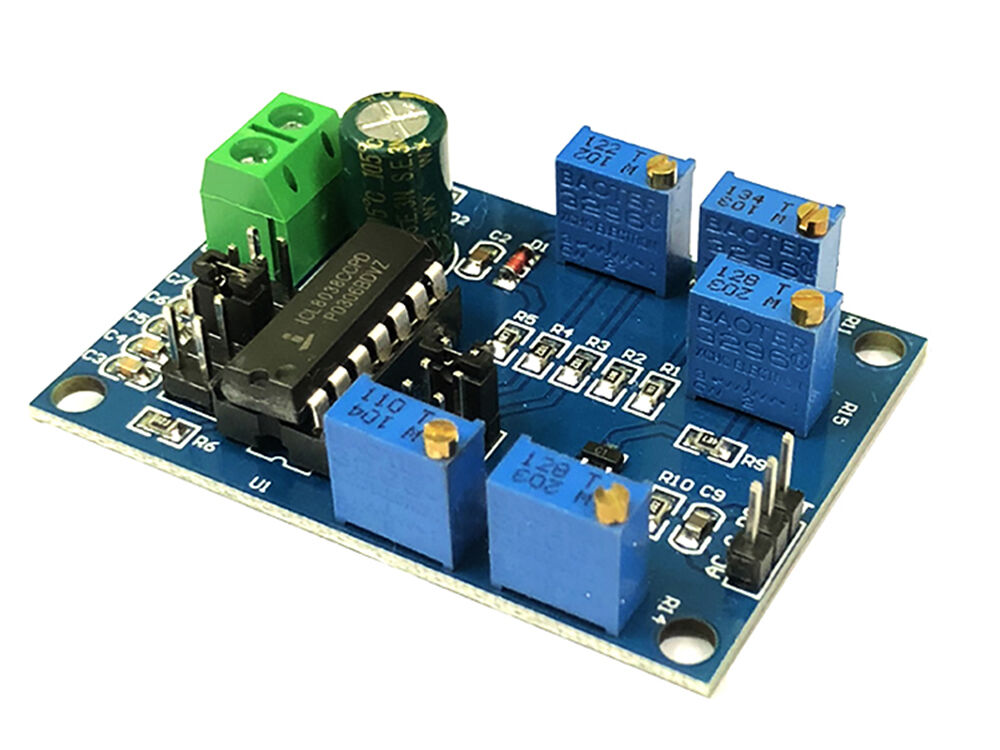

A PCBA (Printed Circuit Board Assembly) is a fully assembled electronic board where all the electronic components—such as resistors, capacitors, transistors, diodes, and integrated circuits—are mounted and soldered onto a bare PCB (Printed Circuit Board). The process transforms a simple PCB into a functioning module that can perform a specific set of tasks in an electronic device.

PCBA involves multiple steps, including:

A PCBA is the heart of any electronic product. It enables circuit functionality by connecting, powering, and integrating the necessary electronic parts. Without a well-assembled PCBA, most modern electronics—from smartphones and laptops to automotive controls and medical devices—would not operate reliably.

When it comes to the assembly of printed circuit board assemblies (PCBAs), there are two main PCBA assembly techniques widely used in the electronics industry:

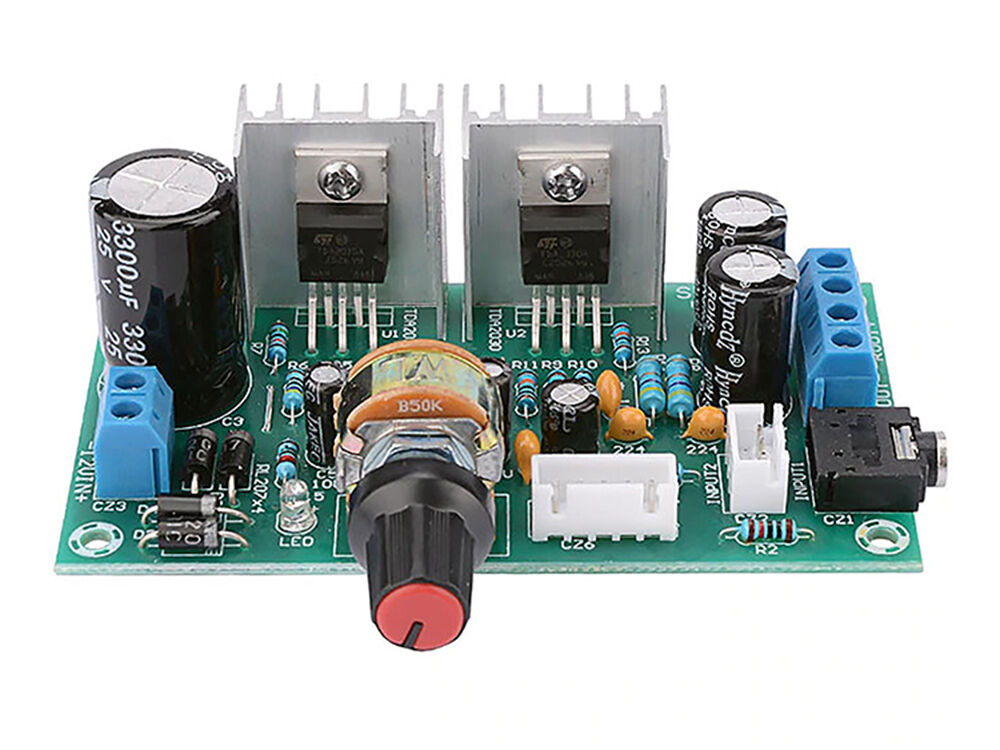

Surface Mount Technology (SMT) is the most common method for assembling modern PCBAs. In SMT, electronic components are directly mounted and soldered onto the surface of the PCB. This technique enables high-speed, automated assembly and allows for the use of smaller, lighter, and more complex components.

Key Benefits of SMT:

Common Applications: Smartphones, computers, automotive electronics, wearables.

Through-Hole Technology (THT) is the traditional method where component leads are inserted into holes drilled into the PCB and then soldered to pads on the opposite side. THT provides strong mechanical bonds and is often used for larger or heavy-duty components that require secure connections.

Key Benefits of THT:

Common Applications: Power supplies, industrial controls, military and aerospace equipment.

Summary Table:

|

Technique |

Component Placement |

Key Strengths |

Typical Use Cases |

|

SMT |

On PCB surface |

High density, speed |

Consumer gadgets, small tech |

|

THT |

Through board holes |

Strength, durability |

Power devices, heavy industry |

Printed circuit boards (PCBs) and printed circuit board assemblies (PCBAs) are the backbone of modern electronics, supporting nearly every facet of technology in today’s world. But what are the most important applications of PCB and PCBA in industry, and how do these components power innovations across sectors? In this article, we break down how PCBs and PCBAs are used in key industries, their unique advantages, and future trends shaping electronic manufacturing.

A printed circuit board (PCB) is a flat, insulating board fitted with conductive pathways, pads, and other features designed to mechanically support and electrically connect electronic components. PCBs are manufactured in multiple layers and provide a reliable foundation for circuit construction.

PCBA stands for Printed Circuit Board Assembly. It refers to a finished PCB that has all necessary electronic components—such as resistors, capacitors, transistors, and integrated circuits—mounted and soldered onto its surface. While a PCB is the board itself, a PCBA is a fully functional assembly, ready for installation into an electronic device.

|

Feature |

PCB |

PCBA |

|

Description |

Bare board only, no electronic components |

Assembled board, with components |

|

Function |

Foundation for circuits |

Operational circuit with components |

|

Manufacturing Step |

Initial process (fabrication) |

Final step (after assembly) |

PCBs and PCBAs are found in almost every technical product and process. Here’s a look at the main sectors benefiting from their integration.

Modern vehicles rely heavily on electronic systems for performance, safety, and convenience. Applications include:

PCBA in automotive: Enhanced reliability, miniaturization, and ruggedness for harsh environments.

Consumer electronics is the fastest-growing sector for PCB application, found in:

The communication industry requires PCBs for reliable, high-speed data transmission:

Medical technology demands high-reliability PCBAs, including:

Factory automation and robotics depend on robust PCB/PCBA systems:

PCBs must meet the strictest reliability standards in this sector:

Sustainable tech uses advanced PCBs and PCBAs for:

PCBs and PCBAs offer compelling advantages, including:

As technology advances, so do PCBs and PCBAs. Major trends include:

Circuit board assembly—commonly known as PCBA—is the process of mounting and soldering electronic components (such as resistors, capacitors, and ICs) onto a bare printed circuit board (PCB). This transforms the board into a working module that powers electronic devices.

Component placement can be performed using automated machines (commonly in Surface Mount Technology, or SMT) or manually (more common with Through-Hole Technology, or THT). Accurate placement is crucial for reliable device function and is typically followed by soldering and inspection steps.

“Rework” refers to correcting or replacing faulty or misplaced components on a PCBA after initial assembly. This process can involve desoldering, cleaning, re-attaching, and re-testing to restore proper function to the circuit board.

Flux cleans and prepares metal surfaces for soldering, improving bond strength and preventing oxidation during assembly. The solder mask is a protective layer applied to the PCB that prevents solder bridges, reduces the risk of short circuits, and protects traces from environmental damage.

Common materials in PCBA assembly include:

Typical PCBA testing methods include:

PCBA manufacturing lead times can range from a few days for prototypes to several weeks for mass production. Speed depends on factors like design complexity, part availability, manufacturing process, and testing requirements.

A bare PCB (just the board) is generally much cheaper than a PCBA (board plus all components and assembly). The cost of a PCBA includes materials, assembly labor, inspection, and testing—making it several times more expensive than a PCB alone.

Hot News

Hot News2026-01-17

2026-01-16

2026-01-15

2026-01-14

2026-01-13

2026-01-12

2026-01-09

2026-01-08