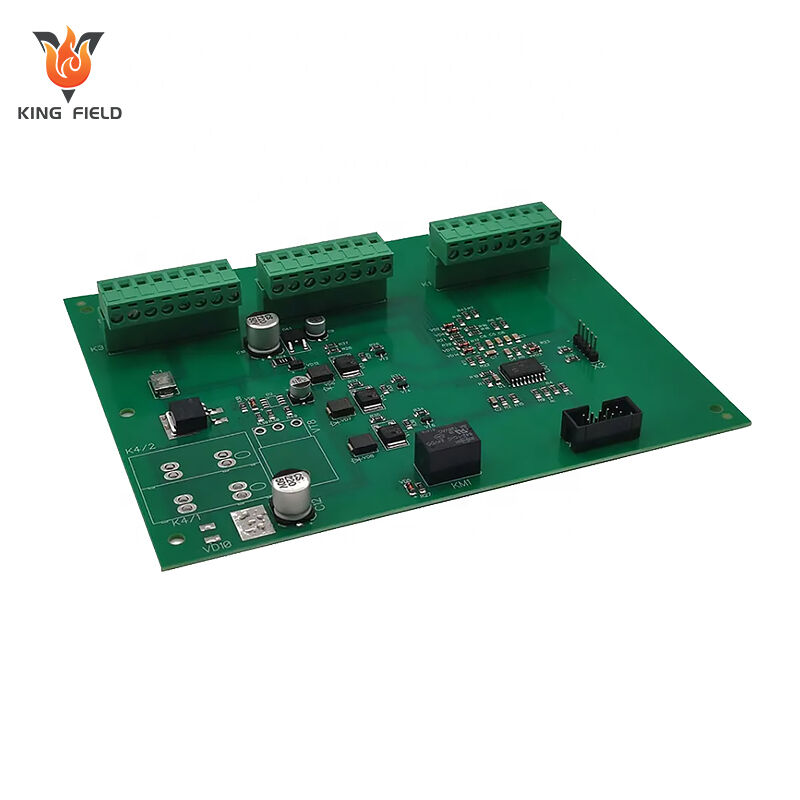

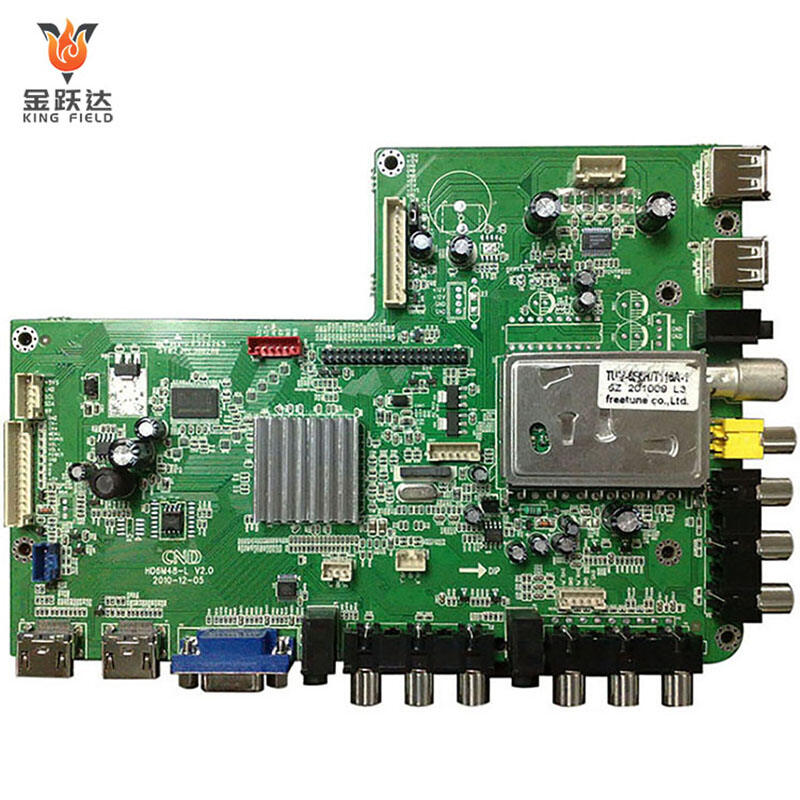

PCB Design

Professional PCB Design services for medical, industrial, automotive & consumer electronics. From schematic capture to DFM-optimized layouts, our expert team ensures signal integrity, manufacturability, and alignment with your R&D goals. Fast turnaround, industry-specific expertise, and end-to-end support—turn your concepts into production-ready designs.

✅ DFM-focused optimization

✅ Schematic to gerber delivery

✅ Signal integrity guarantee

Description

PCB design

PCB Design Overview

PCB design is the foundational process of creating a blueprint for electronic circuits—translating schematic diagrams into physical layouts that enable component mounting, electrical connectivity, and optimal performance.

Core Purpose of PCB Design

Convert electrical schematics into a manufacturable physical layout.

Ensure signal integrity, power distribution, and thermal management for reliable device operation.

Optimize size, weight, and cost while meeting technical requirements.

Common PCB Design Types

| Design Type | Description | Applications | |||

| Rigid PCB Design | Fixed, FR-4 based layouts | Consumer electronics, industrial controls | |||

| Flexible PCB Design | Bendable PI/PET substrates | Wearables, automotive dashboards | |||

| Rigid-Flex PCB Design | Combined rigid and flexible sections | Aerospace avionics, compact IoT devices | |||

| High-Frequency PCB | Optimized for signal integrity | Communication equipment, radar systems | |||

| Miniaturized PCB | Dense layouts with micro-components | Wearables, medical devices | |||

Critical Design Considerations

·Trace Width/Spacing: Follow IPC standards to ensure fabrication feasibility.

·Component Clearance: Avoid overcrowding for soldering access and heat dissipation.

·Thermal Management: Place high-power components with adequate spacing or heat sinks.

·Test Points: Add test pads for post-assembly inspection.

·Bend Radius: For flexible PCBs, maintain minimum bend radius to prevent trace damage.

Kingfield’s PCB Design Support

·DFM Review: Free pre-production design checks to identify manufacturability issues.

·Custom Design Services: End-to-end design for R&D prototypes or high-volume production.

·Compatibility Assurance: Align design with our assembly capabilities.

·Fast Iteration: Support design modifications for prototypes to accelerate time-to-market.

Whether you need to optimize an existing design or create a new PCB from scratch, Kingfield’s technical expertise ensures your design is manufacturable, reliable, and cost-effective. Contact our team to discuss your project requirements!

PCB Design Process

PCB Design Flow

1. Pre-Design Preparation

· Define Requirements: Clarify technical specs, form factor (size/weight), environment (temperature, vibration), and manufacturing constraints.

· Schematic Capture: Use EDA tools to draw component connections; include part numbers, values, and footprints.

· Component Sourcing & Verification: Confirm component availability and validate footprints to avoid assembly issues.

· Electrical Rule Check: Fix short circuits, incompatible components, or missing connections before layout.

2. PCB Layout Design

2.1 Setup Design Parameters

Define PCB size, shape, and layer stackup.

Set manufacturing rules: Trace width/spacing, hole sizes, pad clearances.

2.2 Component Placement

Place critical components first for optimal signal flow.

Follow DFM principles: Avoid overcrowding, ensure soldering access, and separate high-power/heat-generating components.

2.3 Trace Routing

Route signal traces: Optimize length and width.

Prioritize differential pairs and high-frequency traces for signal integrity; add ground planes to reduce noise.

Avoid sharp angles and crossing traces.

2.4 Design Rule Check

Run DRC to validate against layout rules.

Fix errors to ensure manufacturability.

3. Post-Layout Optimization & Verification

·Thermal Analysis: Simulate heat distribution and adjust component placement/heat sinks for high-power designs.

·Signal Integrity (SI) Simulation: Test high-frequency signals for reflection, crosstalk, or delay.

·DFM Review: Collaborate with Kingfield’s engineers to identify issues and optimize for assembly.

·Silkscreen & Solder Mask Setup: Add component labels, logos, and test points; define solder mask openings.

4. File Output & Handover to Manufacturing

·Generate Production Files: Export Gerber files, BOM (Bill of Materials), and pick-and-place files (for assembly).

·File Verification: Kingfield’s team reviews files to ensure compatibility with our fabrication/assembly processes.

·Prototype Order: Submit files for prototype production (3–7 business days) to test form, fit, and function.

5. Prototype Testing & Iteration

·Functional Testing: Validate the prototype’s electrical performance.

·Design Iteration: Adjust layout based on test results.

·Final Design Lock: Approve the optimized design for mass production.

Kingfield’s Support Throughout the Flow

·Pre-Design: Free requirement analysis and component sourcing support.

·Layout Phase: DFM reviews and custom stackup design for high-frequency/flexible PCBs.

·File Handover: Dedicated engineers verify production files and resolve compatibility issues.

·Prototyping: Fast prototype lead times + testing support to accelerate iteration.

Our PCB Design Services

1. Custom PCB Design

Schematic Capture: Convert your electrical concepts into EDA-ready schematics.

Component Selection & Sourcing: Access our global supplier network for verified, traceable components.

Layout Design: Optimized for signal integrity, thermal management, and space efficiency.

Layer Stackup Engineering: Tailored stackups for multi-layer PCBs and high-frequency applications.

2. Specialized Design Solutions

| Design Type | Key Applications | Technical Highlights | |||

| Rigid PCB Design | Consumer electronics, industrial controls, medical devices | FR-4/low-loss materials, dense component placement (01005 size support) | |||

| Flexible PCB Design | Wearables, automotive dashboards, IoT sensors | PI/PET substrates, 3D routing, minimum bend radius optimization | |||

| Rigid-Flex PCB Design | Aerospace avionics, compact IoT modules | Hybrid rigid-flex integration, weight reduction | |||

| High-Frequency PCB Design | 5G equipment, RF modules, radar systems | Controlled impedance, crosstalk minimization | |||

3. Design Verification & Optimization

Electrical Rule Check: Eliminate short circuits, incompatible components, and connection errors.

Design Rule Check: Validate against manufacturing constraints.

Signal Integrity Simulation: Test high-frequency signals for reflection, delay, and crosstalk.

Thermal Analysis: Optimize heat distribution for high-power components.

4. DFM Review & File Preparation

Free pre-production DFM reviews to identify manufacturability issues upfront.

Generate production-ready files: Gerber, BOM, pick-and-place, and assembly drawings.

File verification to ensure compatibility with Kingfield’s fabrication/assembly processes.

Why Choose Kingfield for PCB Design?

At Kingfield, we blend industry expertise, IPC compliance, and manufacturing-centric design to deliver PCBs that balance performance, cost, and scalability. Our end-to-end design services cater to prototypes, high-volume production, and specialized applications—backed by 20+ years of experience in rigid, flexible, and rigid-flex PCB design.

| Core Advantage | Details | ||||

| DFM-First Approach | Design optimized for manufacturability from day one, reducing rework and production delays. | ||||

| IPC-Certified Standards | Adheres to IPC-2221/2222/2223 standards for reliable, industry-compliant designs. | ||||

| Multi-Technology Expertise | Specializes in rigid, flexible, rigid-flex, high-frequency (5G/RF), and miniaturized PCBs. | ||||

| Fast Iteration Cycles | 3–7 day prototype turnaround + real-time engineering support to accelerate time-to-market. | ||||

| Full Turnkey Integration | Seamlessly connects design with our in-house PCB fabrication and assembly services. | ||||