Electronics drive today’s digital transformation, enabling smartphones, medical diagnostics, next-gen vehicles, and IoT. At their core is electronics manufacturing: a precise, specialized process turning designs into functional, reliable products.

Electronics Manufacturing Services (EMS) and Electronics Contract Manufacturing (ECM) have transformed how OEMs launch products. Beyond PCB assembly (PCBA), the journey from schematic to finished device requires top-tier quality control, agile supply chains, and expert knowledge to mitigate risks and speed time to market.

Electronics manufacturing turns electronic designs/components into finished, ready-to-use products. It integrates circuit design, PCB fabrication/assembly (PCBA), component sourcing, and system integration—aiming to efficiently, reliably, and cost-effectively convert concepts into safe, functional, mass-producible devices.

|

Stage |

Description |

Key Activities |

|

Design & Engineering |

Translating requirements into schematics and PCB layouts |

DFM checks, stack-up, BOM creation |

|

PCB Fabrication |

Manufacturing “bare” printed circuit boards from digital files |

Imaging, drilling, plating, finishing |

|

Component Procurement |

Sourcing and verifying electronic parts, managing the supply chain |

Supplier vetting, counterfeit prevention |

|

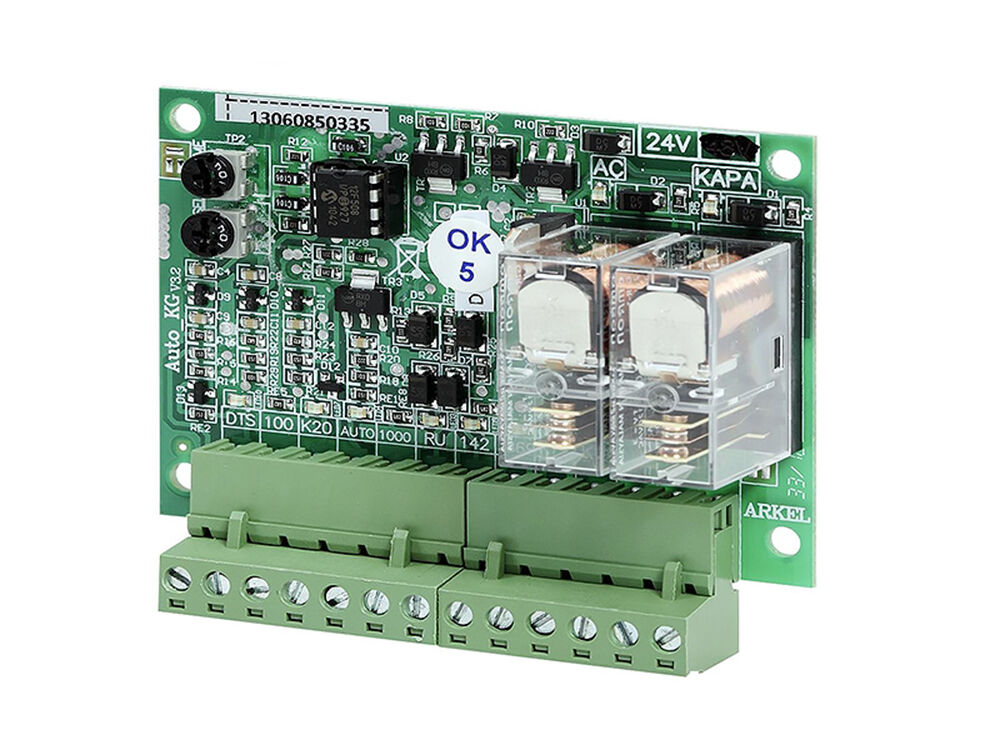

PCB Assembly (PCBA) |

Mounting components onto boards (SMT, through-hole) and soldering processes |

Pick-and-place, reflow, wave soldering |

|

Testing & Inspection |

Ensuring function and quality with automated, visual, and electrical inspections (AOI, X-ray, ICT, FCT) |

AOI, X-ray, functional tests, DPPM analysis |

|

Box Build & Integration |

Assembling PCBA into end products, packaging, and preparing for shipment |

Mechanical assembly, final testing, packing |

|

Industry |

Core Applications |

Special Considerations |

|

Consumer |

Smartphones, wearables, home devices |

Cost, time to market, quick-turn |

|

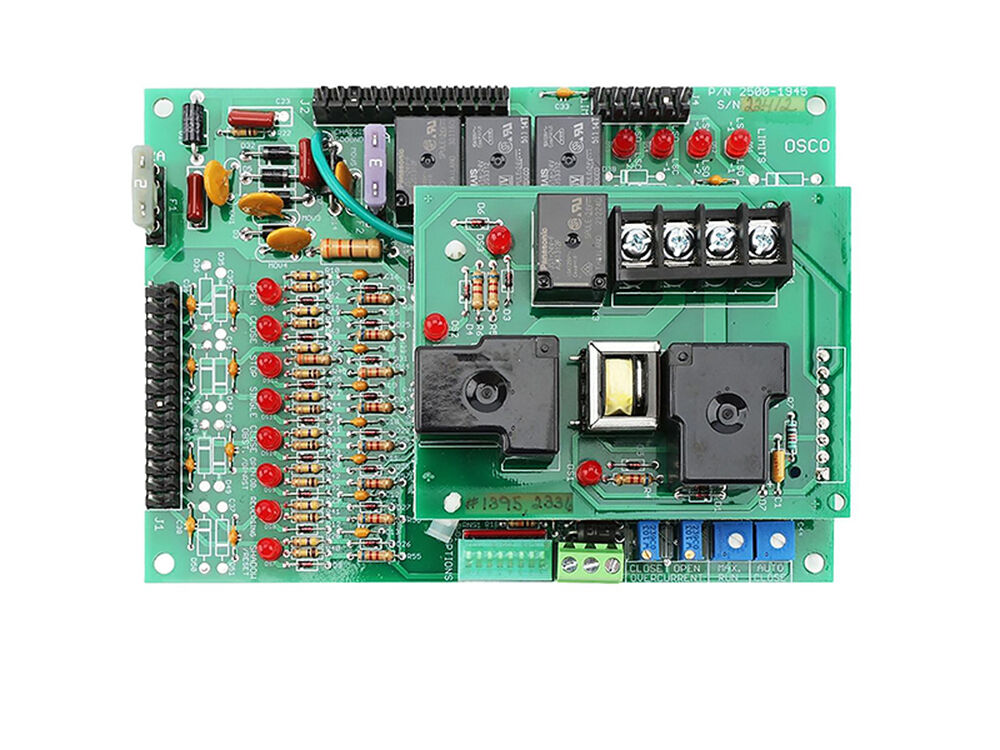

Automotive |

ADAS systems, infotainment, controls |

IATF 16949 certified, traceability |

|

Medical |

Diagnostics, monitoring, therapeutic equipment |

ISO 13485, biocompatibility, safety |

|

Communications |

Routers, base stations, fiber components |

RF/EMI expertise, reliability |

|

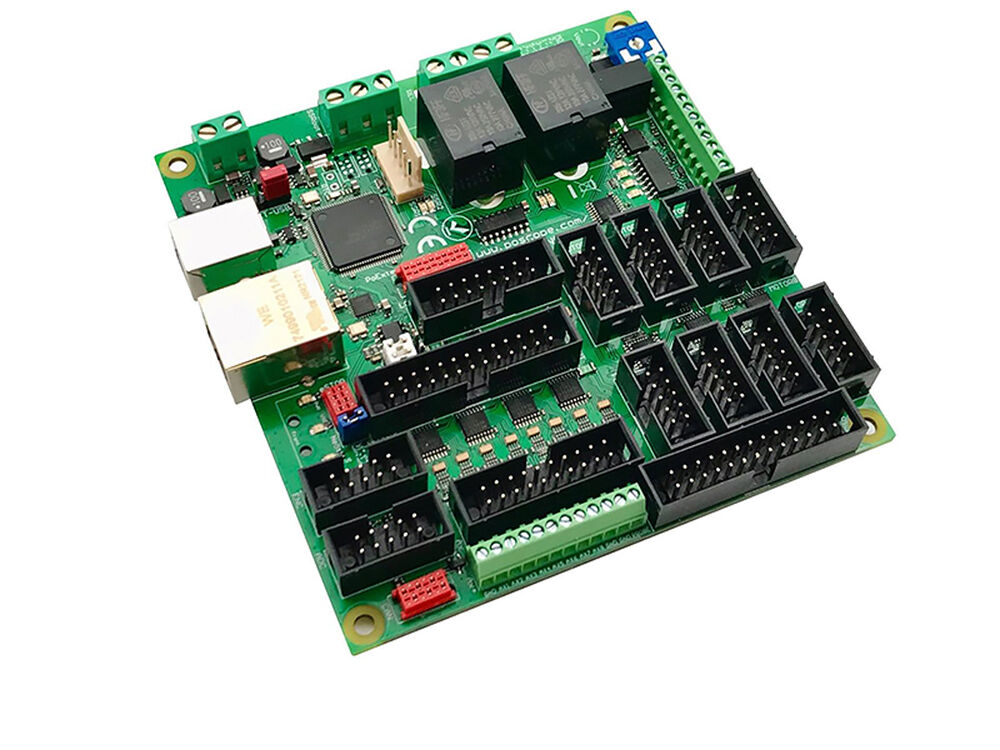

Industrial/IoT |

Controls, automation, sensors, gateways |

Extended temp, robust assembly |

|

Aerospace/Defense |

Navigation, avionics, mission-critical controls |

MIL spec, extreme environmental testing |

Quality is not optional—especially in safety-critical applications. Poor PCB assembly or incomplete testing can cause catastrophic field failures, product recalls, and severe financial and reputational losses. A robust quality control system—combining standards such as IPC-A-610 (acceptability), AOI, X-ray, FCT, and in-circuit tests—directly translates into:

|

Certification |

Industry Focus |

Importance |

|

ISO 9001 |

General, all industries |

Standardized processes, continuous improvement, customer satisfaction |

|

ISO 13485 |

Medical devices |

Stringent traceability, risk management, compliance |

|

IATF 16949 |

Automotive |

Zero-defect, supplier management, best practices for automotive PCBs |

|

UL, RoHS/REACH |

Safety, environmental |

Flammability (UL 94V-0), restricted substances, European compliance |

|

IPC-A-610/600/J-STD-001 |

Electronics/PCB |

Soldering, assembly quality, workmanship |

Electronics Manufacturing Services (EMS) are third-party firms providing end-to-end electronic product design, assembly, and testing for OEMs. As specialized partners, they support scaling from prototype PCB development to volume/box build production—eliminating the need for OEMs to own factories.

EMS is favored by startups, established brands, and companies aiming for fast, high-quality product launches with cost and supply chain control. Trusted EMS providers let OEMs focus on R&D, design, and marketing, while managing manufacturing logistics, technical processes, and regulatory compliance.

|

EMS Service |

Description |

Value to OEMs |

|

Component Procurement & Supply Chain Management |

End-to-end component sourcing, verifying part authenticity, lifecycle monitoring |

Prevents counterfeits, manages obsolescence, optimizes cost and inventory |

|

PCB Assembly (SMT & Through-Hole) |

Automated surface-mount (SMT), through-hole, or mixed technology assembly |

Ensures high-quality, reliable attachment of components, including complex BGA assembly |

|

Testing & Quality Control |

Multi-stage inspection: AOI, X-ray, In-Circuit Test (ICT), Functional Testing (FCT) |

Delivers zero-defect products, regulatory compliance, and customer satisfaction |

|

Box Build Assembly |

Final integration, wiring, enclosure installation, system-level testing, labeling/packaging |

Enables turnkey delivery of “ready for shelf” or “ready for deployment” end products |

|

Quick-Turn Prototyping & NPI |

Rapid build and test of prototype PCBs and New Product Introductions (NPI) |

Accelerates design cycles, reduces time to market, refines manufacturability |

Electronics Contract Manufacturing (ECM) is a specific form of outsourcing in which an OEM (Original Equipment Manufacturer) entrusts the full production of their products to a specialized third-party called a contract electronics manufacturer. Unlike generic EMS—which can be modular, covering some or all aspects from design to fulfillment—ECM relationships are typically governed by a contract that details every technical and supply term, including drawings, quality standards, test procedures, delivery quantities, and intellectual property (“IP”) protections.

A trusted ECM supplier does more than just “build to print.” Modern ECMs provide:

While both EMS and ECM offer electronics manufacturing services, their business models can differ:

|

|

ECM |

EMS |

|

Focus |

Pure contract/built-to-print; fully specified by OEM |

May offer design, prototyping, and NPI flexibility |

|

Relationship |

Defined by contract, fixed specs & standards |

Modular, can cover any subset of value chain |

|

Volume |

Often favors medium/large-scale production |

Flexible to low- or high-volume, high-mix |

|

Ownership |

OEM retains all design; ECM ensures manufacturing execution |

EMS may participate in co-design/DFM/NPI |

Choosing an Electronics Contract Manufacturer provides critical strategic advantages, especially when scaling from prototype to mass production:

|

Risk |

Best Practice Solution |

|

Component shortages |

BOM robustness checks, multi-source planning |

|

Process deviations |

Regular audits, enforce change control |

|

Counterfeit part risk |

Source traceability, X-ray/component validation |

|

Documentation errors |

Cross-validation with prototype sample builds |

|

Factory closure/transfer |

Secure all working files, physical reference samples, cross-section analysis |

Design for Manufacturability (DFM), Design for Assembly (DFA), and Design for Testability (DFT) checks are vital first steps. Top EMS and ECM providers use advanced tools (like HQDFM or Valor NPI) to analyze Gerber X2, IPC-2581, or ODB++ data, stack-up, panel utilization, trace width/spacing, and testability.

BOM (Bill of Materials) analysis determines the real-world buildability and supply chain robustness. A thorough review identifies obsolete or EOL (End-of-Life) parts, high-risk custom ICs, and provides cost-saving alternate sourcing options—crucial for minimizing lead times and preventing counterfeit part procurement.

Before scaling to mass production, quick-turn PCB prototypes are built and assembled using actual components intended for the final run. This phase uncovers:

As global supply chains become more complex, ensuring the availability, authenticity, and traceability of every part on the BOM is paramount. EMS providers leverage:

|

Risk |

Mitigation Strategy |

|

Obsolete/EOL part |

Lifecycle monitoring & last-time-buy alerts |

|

Counterfeit part |

Anti-counterfeit procedures, trusted suppliers, X-ray check |

|

Supply chain interruption |

Dual-sourcing, regional buffer stock, logistics coordination |

|

Price volatility |

Volume contracts, transparent quoting |

Environmental and Material Controls:

|

Test/Inspection |

Purpose |

Tools/Methods |

When Applied |

|

SPI |

Verify solder paste alignment/volume |

Inline 3D SPI |

Post-stencil, pre-pick and place |

|

AOI |

Visual for solder, placement, orientation |

2D/3D AOI cameras |

Post-reflow, post-THT |

|

X-ray Inspection |

Verify BGA/LGA/QFN connectivity, voids |

Inline/offline X-ray |

After reflow, BGA/hidden joints |

|

ICT |

In-circuit test for opens/shorts/isolation |

Bed-of-nails/flying probe |

PCBAs with test points |

|

FCT |

Validate circuit function under voltage/load |

Custom test jigs |

End of line, sample or 100% |

|

ROSE/Ionic Tests |

Residual cleanliness, contamination control |

ROSE, Ion chromatography |

Medical/aerospace/auto assemblies |

|

Step |

Key Focus Areas |

Best Practices |

|

Design Review & BOM Analysis |

DFM, Obsolescence, Cost |

Early engineering input, HQDFM, multi-source |

|

Prototype Assembly & Test |

Buildability, Risk Assessment |

Use “gold sample”, cross-vendor check |

|

Component Procurement |

Sourcing, Authenticity, Lead Time |

Central warehouse, anti-counterfeit, BOM hub |

|

PCB Fabrication |

Stack-up, Specs, Electrical Test |

IPC-6012/600, ENIG/HASL, microvias |

|

SMT/THT Assembly |

Process Precision, ESD, MSD |

SPI, AOI, X-ray, ANSI/ESD protocols |

|

Testing & Inspection |

Quality, Reliability, Compliance |

ICT, FCT, ROSE/IC for critical apps |

|

Box Build & Logistics |

System Assembly, Packaging |

Burn-in, serial number traceability |

|

Protection & Rework |

Conformal Coating, Repair |

IPC-CC-830, 7711/7721, QMS trace |

In electronics manufacturing, quality assurance is the cornerstone of product reliability, regulatory compliance, and customer trust. As advanced PCBs become more intricate and electronic products find their way into safety-critical fields—medical devices, automotive control, aerospace navigation—the demand for robust, globally recognized quality management systems (QMS) and certifications has never been higher.

A world-class EMS or ECM provider doesn’t only implement flawless SMT processes or AOI/X-ray procedures; they build an integrated, traceable QMS culture monitored and audited by both internal experts and third-party regulators. This both minimizes the risk of defects and ensures consistent, repeatable results—batch after batch and over the entire product lifecycle.

Below is a summary table of the most critical QMS and product certifications in the electronics industry, their primary audience, and why they matter:

|

Certification |

Applicability / Industry |

What It Ensures |

|

ISO 9001 |

General, all industries |

Standardized QMS, continuous improvement, process discipline |

|

IATF 16949 |

Automotive electronics |

Automotive-specific controls, defect prevention, supply chain rigor |

|

ISO 13485 |

Medical device manufacturing |

Risk management, full traceability, regulatory compliance for medical |

|

UL Certification |

Safety-critical, consumer |

Electrical/fire safety (e.g., UL 94V-0 flammability for PCBs) |

|

RoHS/REACH |

EU compliance, global export |

Restricted hazardous substance control, environmental safety |

|

IPC Standards |

All electronics (global) |

Workmanship (IPC-A-610), bare PCB (IPC-6012 / IPC-A-600), solder (J-STD-001), rework/repair (IPC-7711/7721) |

A professional QMS in electronics manufacturing is more than a label—it is a system for:

A European tier-1 auto supplier required IATF 16949 certified PCBAs for ADAS modules. By engaging a multi-factory EMS provider in Shenzhen (for prototyping and PPAP) and Huizhou (for mass production), the supplier benefitted from:

|

Application Area |

Required Certification(s) |

Typical Additional Checks |

|

Medical |

ISO 13485, UL |

Biocompatibility, full documentation |

|

Automotive |

IATF 16949, ISO 9001, AEC-Qxx |

Traceability, PPAP, FMEA |

|

Consumer |

ISO 9001, UL |

RoHS/REACH, end-of-line burn-in |

|

Industrial/IoT |

ISO 9001, UL, RoHS/REACH |

Environmental stress screening |

|

Aerospace |

AS9100, IPC, custom OEM QMS |

COFC, batch-level and process traceamility |

The modern electronics manufacturing landscape is tightly interwoven with global supply chains, volatile component markets, and customer demands for just-in-time production. To ensure reliable PCB assembly (PCBA) outcomes, EMS and ECM providers must go beyond basic sourcing. They need robust BOM (Bill of Materials) management, proactive risk identification, and intelligent logistics—especially as products become more complex and component lifecycles shorten.

The BOM is the DNA of every electronic product. A single obsolete or counterfeit component can halt your line and compromise customer trust. Robust BOM control strategies include:

EMS leaders have moved to central intelligent warehouses and smart BOM import systems:

|

Supply Chain Risk |

Mitigation Action |

Tools and Techniques |

|

Obsolete/EOL Parts |

Monitor via supply chain software & lifecycle database |

BOM risk reports, supplier portal alerts |

|

Counterfeit Entry |

Trusted suppliers, mandatory X-ray/mark verification |

Visual, X-ray, and electrical test |

|

Delay/Shortage |

Buffer stocks, alternate sourcing, regional warehouses |

Smart inventory, supplier dual-qualification |

|

Quality Drift |

Incoming inspection, certificates of compliance |

AQL sampling, batch serialization, COFC |

|

Documentation Gaps |

Digital recordkeeping, revision control |

ERP/MRP integration, versioned BOM |

Upon arrival, all inbound parts (especially ICs, BGAs, connectors, passives) are verified:

Full traceability reduces your risk exposure and is vital for automotive (IATF 16949), medical (ISO 13485), and aerospace markets:

|

Metric |

Typical Target |

Value for EMS & OEMs |

|

On-time Material Delivery |

>98% |

Smooth project launches, reduced line stops |

|

First Pass Acceptance |

>99.5% incoming batches |

Less rework, higher assembly efficiency |

|

Counterfeit Incidents |

Zero |

Maintains reputation, warranty savings |

|

Lead-time Variance |

<10% |

Predictable schedules, happier customers |

Electronics Manufacturing Services (EMS) providers are indispensable partners across nearly every major industry segment. The expertise, certifications, and manufacturing agility offered by top EMS and ECM partners turn intricate electronic designs into robust, compliant, and market-ready products for a variety of specialized fields.

Explore how EMS processes, standards, and quality disciplines apply to the world’s most demanding application environments:

Scope: From smartphones to wearables, game consoles, audio devices, home automation, and more, consumer electronics are driven by relentless speed-to-market and thin margins. Quick-turn PCB prototyping, supply chain resilience, and ultrafast ramp from prototype to mass production are vital.

EMS Advantages:

Scope: Automotive electronics require absolute reliability, long lifecycle support, and strict regulatory adherence. Application areas include Advanced Driver Assistance Systems (ADAS), infotainment, digital dashboards, engine management, and EV power electronics.

EMS Advantages:

|

Automotive EMS Specialization |

Value Provided |

|

ADAS Module PCB Assembly |

Zero-defect, traceable build, burn-in test |

|

Infotainment PCB |

EMI/ESD design, RF testing, traceability |

|

Inverter/EV Electronics |

Thermal cycling, high-power design |

Scope: Electronics for medical use must meet rigorous standards for reliability, documentation, and patient safety—no exceptions.

EMS Advantages:

Scope: Industrial controls, smart metering, building automation, and a rapidly expanding universe of IoT sensors/devices rely on EMS for scalability, robustness, and continuous design updates.

EMS Advantages:

|

Industry |

Certification Focus |

Special Process/Tech |

Key EMS Value for OEMs |

|

Consumer |

ISO 9001, UL, RoHS |

Quick-turn lines, IoT firmware |

Speed & cost |

|

Automotive |

IATF 16949 |

Traceability, HDI, env. stress |

Reliability, defect prevention |

|

Medical |

ISO 13485, UL |

Cleanliness, full traceability |

Compliance, documentation |

|

Industrial/IoT |

ISO 9001, RoHS |

Box build, stress screening |

Flexibility, NPI agility |

In a fiercely competitive electronics manufacturing landscape, kingfield stands out as a true end-to-end EMS partner—providing everything from prototype PCB assembly and quick-turn services to large-scale, high-certification mass production. Whether you are a startup innovator or a Fortune 500 OEM, kingfield is engineered to de-risk your project, accelerate time to market, and deliver world-class quality—consistently and transparently.

|

Capability |

kingfield Solution |

|

Prototype to Mass Production |

Shenzhen (NPI/proto) |

|

Supported Technologies |

SMT, THT, BGA, LGA, QFN, HDI, flex, rigid-flex |

|

Certifications |

ISO 9001, ISO 13485, IATF 16949, ISO 14001, UL |

|

In-house Specialties |

CNC, fixture/stencil, conformal coating, test dev. |

|

Smart Supply Chain |

BOM importer, instant quoting, traceable warehouse |

|

Core Industries Served |

Automotive, Medical, Consumer, IoT, Industrial |

|

Service Model |

One-stop, turnkey, full traceability, B2B global |

Modern electronics manufacturing providers must balance three critical demands: competitive cost, efficient lead-time, and sustainable, compliant operations. For OEMs, especially those working at global scale or under regulatory scrutiny, understanding these drivers and how an EMS/ECM partner manages them is fundamental to launching successful products.

|

Cost/Lead-Time Factor |

Impacted Area |

Optimization Strategies |

|

Layer Count |

PCB fabrication |

Minimize layers with smart stack-up, DFM |

|

Board Size & Panelization |

Fabrication, PCBA |

Panelize for efficient assembly |

|

Trace Width/Spacing |

PCB reliability, yield |

Use standard sizes unless function dictates |

|

Hole Count/Diameter |

Drilling cost, yield |

Avoid excessive microvias unless critical |

|

Microvias/HDI |

High-density interconnect |

Only when higher I/O density requires |

|

Controlled Impedance |

RF/high-speed applications |

Design for manufacturing tolerances |

|

Surface Finish (ENIG, HASL, etc.) |

Soldering and shelf life |

Choose finish based on assembly/usage and price |

|

Solder Mask Density |

Assembly precision |

DFM review to avoid mask slivers/bridges |

|

Test Strategy (SPI, AOI, X-ray) |

Quality and yield |

Tailor test coverage to product criticality |

|

Data Format & DFM |

Overall manufacturing |

Use Gerber X2, IPC-2581, DFM tools |

|

Project Phase |

Fastest Path |

Common Pitfall |

Best Practice |

|

NPI/Prototyping |

Quick-turn assembly |

Missing BOM alternates |

EMS-led DFM & BOM vetting |

|

Early Mass Run |

Pre-book capacity |

Late ECN/poor docs |

Freeze design early, document |

|

Scaled Production |

Smart supply chain |

Custom finish/specialty |

Standardize wherever possible |

For today’s global market, sustainability and regulatory compliance go hand-in-hand. Customers and regulators expect suppliers to meet not only product specs but also reduce environmental impact and prove responsible sourcing.

|

Term/Abbreviation |

Definition / Importance |

|

PCB (Printed Circuit Board) |

Substrate supporting electronic components and traces for connectivity |

|

PCBA |

Printed Circuit Board Assembly—populated board with all required components |

|

EMS |

Electronics Manufacturing Services—a company offering design-to-box manufacturing |

|

ECM |

Electronics Contract Manufacturing—a company producing per OEM specs/drawings |

|

OEM |

Original Equipment Manufacturer—brand owner who outsources production |

|

SMT |

Surface Mount Technology—parts are placed/soldered onto board surface |

|

THT |

Through-Hole Technology—parts are soldered into drilled holes in the PCB |

|

BOM |

Bill of Materials—full list of components required for assembly |

|

DFM |

Design for Manufacturability—design reviews aimed at preventing manufacturing issues |

|

DFA |

Design for Assembly—design optimization for easy and robust assembly |

|

DFT |

Design for Testability—making products easier to test and diagnose |

|

SPI |

Solder Paste Inspection—monitoring paste volume/placement prior to pick-and-place |

|

AOI |

Automated Optical Inspection—visual check for solder and component errors post-assembly |

|

AXI |

Automated X-ray Inspection—crucial for BGAs and leadless devices |

|

ICT |

In-Circuit Test—verifies electrical connections and component values |

|

FCT |

Functional Circuit Test—validates the operational functionality of the assembly |

|

IPC-6012 |

Standard for PCB qualification and performance requirements |

|

IPC-A-600 |

Standard for visual acceptance of bare PCBs |

|

IPC-A-610 |

Criteria for acceptability of electronic assemblies |

|

ISO 9001 |

Quality management certification for consistent process and improvement |

|

IATF 16949 |

Automotive sector QMS standard |

|

ISO 13485 |

Medical device manufacturing QMS standard |

|

ISO 14001 |

Environmental management systems standard |

|

UL |

Underwriters Laboratories certification for safety/flame retardancy |

|

RoHS/REACH |

Directives restricting hazardous substances and documentation in products |

|

HDI |

High Density Interconnect—advanced PCB with fine lines and microvias |

|

MSD |

Moisture Sensitive Device—requires specific handling and storage |

|

ESD |

Electrostatic Discharge—risk to sensitive electronics, requires strict controls |

|

DFx |

Design for Excellence—umbrella term for DFM, DFA, DFT, etc. |

In today’s complex, fast-moving world of electronics manufacturing, achieving consistent product quality, rapid time to market, and regulatory confidence requires far more than simply outsourcing production. It calls for deep partnerships with qualified, proven, and innovative Electronics Manufacturing Services (EMS) and Electronics Contract Manufacturing (ECM) providers—especially those who understand the realities of global supply chains, design validation, and quality assurance.

ECM focuses on a “build-to-print” approach—manufacturing products strictly to the customer’s provided drawings and specifications, often for mid- or high-volume production. EMS can be broader, sometimes including design, prototyping, and test development in addition to mass manufacturing and assembly.

Leading EMS partners use:

Quality control systems (including ISO 9001, ISO 13485, IATF 16949, AOI, X-ray, and functional testing) assure that electronics meet rigorous international standards for reliability, safety, and compliance—essential for reducing warranty claims, avoiding recalls, and building customer trust.

Quick-turn PCB assembly in China offers industry-leading speed and cost, particularly for rapid prototyping or small-to-medium batch runs. However, for extremely IP-sensitive or highly regulated applications, some OEMs may prefer a domestic partner. Many global innovators blend both strategies to maximize speed and control.

Look for partners certified to:

Hot News

Hot News2026-01-17

2026-01-16

2026-01-15

2026-01-14

2026-01-13

2026-01-12

2026-01-09

2026-01-08