Through multilayer PCB assembly, the electronics industry has been able to come up with various high-performance devices ranging from medical instruments, automotive parts, telecommunications infrastructure to industrial automation. As the products keep on advancing, it is still very crucial that multilayer PCB assembly is done with the utmost precision. Why is precision so vital and what are the consequences of not having it?

What Multilayer PCB Assembly Actually Is

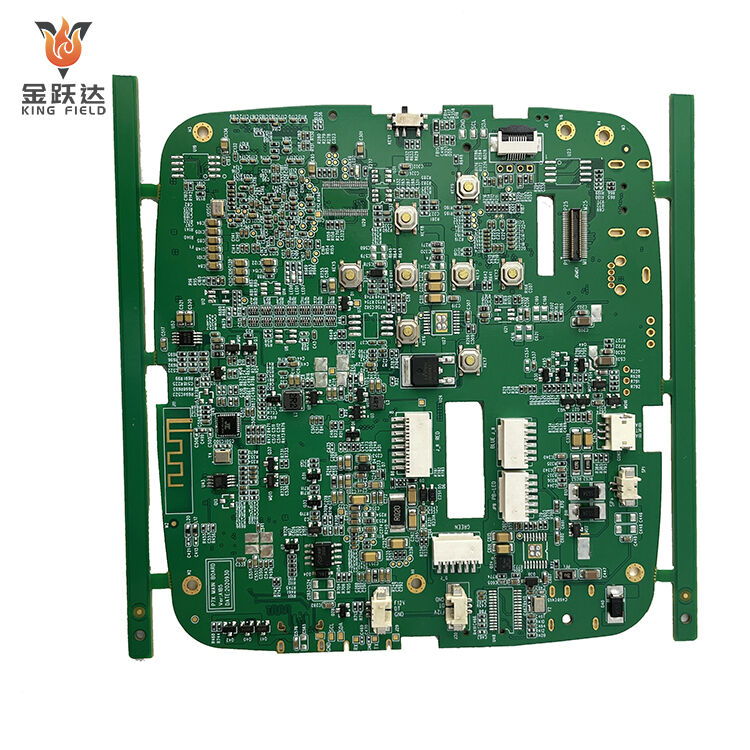

Multilayer PCB assembly is different from single-layer or double-sided boards in that it involves stacking and interconnecting several layers of copper conductor and insulating material which are all tightly packed. Different layers may contain very high-speed digital circuits, power, and sensitive analog circuits, within a thickness of only a few millimeters.

While adding layers does increase the circuits count, it also increases the functionalities of the circuits and thus the possibility of errors cannot be ruled out. A tiny mistake such as misalignment, a drilling deviation, or registration between layers can lead to circuit malfunction as these minor faults may cause signal discontinuity, impedance mismatch, or even the rejection of the board.

Signal paths, impedance matching, and overall board performance are some of the problems that one and only precision way can solve i.e. by having all layers perfectly aligned and the board functioning as a single electrical system.

Signal Integrity Depends Highly on Precision

Signal integrity could be the primary reason advanced multilayer PCB assembly is necessary. High-speed digital signals are highly sensitive to trace length, spacing, and the layer positioning. A tiny change in any of these parameters can cause the signal to be reflected, Crosstalk can occur, electromagnetic interference (EMI) can be produced, or the signals may be arriving at different times (timing errors).

Where high precision is allowed, e.g. in trace routing, layer stacking, and dielectric thickness, stable impedance can be maintained and the signal can be kept pure. In fact, this is the real situation in servers, networking equipment, and high-frequency communication devices where the performance margin is very narrow.

Dependability and Longevity

Multilayer PCB applications are generally in the areas where operation without interruption and reliability are the main issues for concern. Among the examples are medical devices, aerospace, industrial equipment, and automotive electronics.

The above-described usage scenarios signify that if your electronic devices can run for a long time without technical faults, then you very accurate with the assembly of the multilayer PCB.

Internal stress caused by incorrect positioning or insufficient float can lead to the formation of microcracks, delamination, and even via failures. Inaccurate drilling cannot reach the same level of performance as accurate cross-checking for plating and lamination which will unquestionably result in inter-layer connections with an excellent mechanical strength and homogeneity, thus the PCB will be capable of withstanding thermal cycling, vibration, extended operation, etc.

King Field has made it their responsibility to place emphasis on precision during the whole assembly process so that the multilayer PCBs they manufacture can be confidently utilized for the entire service life.

Miniaturization Tightens Tolerances

Since sharps in electronic gadgets increase, multilayer PCB assembly will need to realize the introduction of more components in tighter spaces. Use of fine-pitch components, microvias, and layers with higher counts, already enable extremely compact installations, leaving virtually no room for component placement errors.

In order to thwart defects, such as solder bridging, tombstoning, or insufficient joints, component placement, solder paste application, and reflow profile are critical and require a very high level of precision. In high-density multilayer configurations, an individual assembly defect can jeopardize a whole bunch of layers at once, hence the key to acceptable yields is precision.

Thermal Management and Power Distribution

Multilayer PCBs are generally designed with power and ground planes to facilitate heat dissipation and to provide stabilized power supply. You could say that the thermal performance and the current carrying capacity to a large extent rely on the precise thickness of layers, the weight of copper, and the alignment of planes.

Improper assembly may result in local overheating, voltage drops, or the generation of electromagnetic noise. Making the multilayer PCB assembly process a precise one is the only way to guarantee an even distribution of power and effective heat dissipation. It is one of the basic requirements for keeping the system running at maximum efficiency and getting the most out of the life of components which are very sensitive to temperature variations.

Cost Control Through Precision

After a closer look, tightly manufactured parts will help save substantial factory cost. Loose multilayer PCB assembly is the cause of an unbearable amount of scrapped parts, reworks, field failures, and warranty claims.

This is why, through process discipline and precision, King Field, for instance, is in a great position to help its clients achieve higher first-pass yields and more predictable production results. Besides a technical requirement, precision is a strategic investment in quality, efficiency, and customer perception of your brand.

Expertise and Process Control

It takes not only the latest cutting-edge equipment to produce multilayer PCBs but also considerable technical knowledge, good process management, and rigorous quality inspection to produce precision. Whether it is material choice, stack-up planning, automated optical inspection, or electrical testing, these require that every step is planned and executed with the utmost care.

An experienced manufacturer knows how different final results may be obtained by making slight changes in the process and can, therefore, take the necessary precautions to prevent problems before they arise. What puts King Field in that particular league is the fact that they have on board engineers not only with specializations but also have the necessary experience to apply the most accurate manufacturing practices and thereby consistently deliver flawless multilayer PCB assemblies.

As discussed throughout this piece precision has enabled multilayer PCB assembly to achieve a level of signal integrity to a large extent, serve long-term reliability, facilitate miniaturization, improve thermal management, and contribute to the lowest total cost of ownership.

However, as electronic devices evolve at an unprecedented speed, precision is guaranteed to play a central role in the production of circuit boards.

So, if you want to derive the full commercial advantage of your multilayer PCB assemblies, it is only sensible to buy through a manufacturing facility that is not only equipped but also well-trained for the job, such as King Field, and whose operating accuracy, process control, and competence form the basis of your decision.