As electronic products are miniaturized, sped up, and made more complex, PCB printed assembly quality is becoming increasingly important. The reason is a well-assembled PCB serves as the backbone for reliable electronic performance whereas a poorly assembled PCB results in frequent failures, unstable signals and costly recalls. Designers, engineers and procurement teams should be well aware of the factors that affect printed PCB assembly quality if they want the products to succeed for the long term.

Thoughtful PCB Design and Layout

Quality printed PCB assembly means a quality design. A carefully optimized PCB layout will make the assembly process not only quick and easy but also help guarantee reliable electrical performance. Things such as trace routing, component spacing, pad sizes, and thermal management should be thoroughly considered.

If the design ignores the assembly process, there will be more soldering defects, component misalignment, or rework during the production. The issues can be detected before the fabrication by running the Design for Manufacturability (DFM) and Design for Assembly (DFA) analyses.

King Field, for instance, normally conducts design reviews in which they help customers to improve their PCB layouts so that assembly can be performed more quickly and with fewer defects.

Material Selection and Component Reliability

Top-notch materials make printed PCB assembly more durable and high-performing. Premium-grade substrates like the highly stable FR-4 and specialized high-frequency materials have remarkable thermal resistance and mechanical stability. Besides copper thickness, solder mask quality, and surface finishes also play a role in solderability and long-term reliability.

Nevertheless, the choice of electronic components is equally vital.Genuine, well-tested components are a sure way to stable operation and the least chance of early failure. Poor-quality or counterfeit components can degrade even the most well-assembled PCB.

King Field pursues strict material sourcing and component verification policies so as to keep quality high for each printed PCB assembly project.

Precision in the Assembly Process

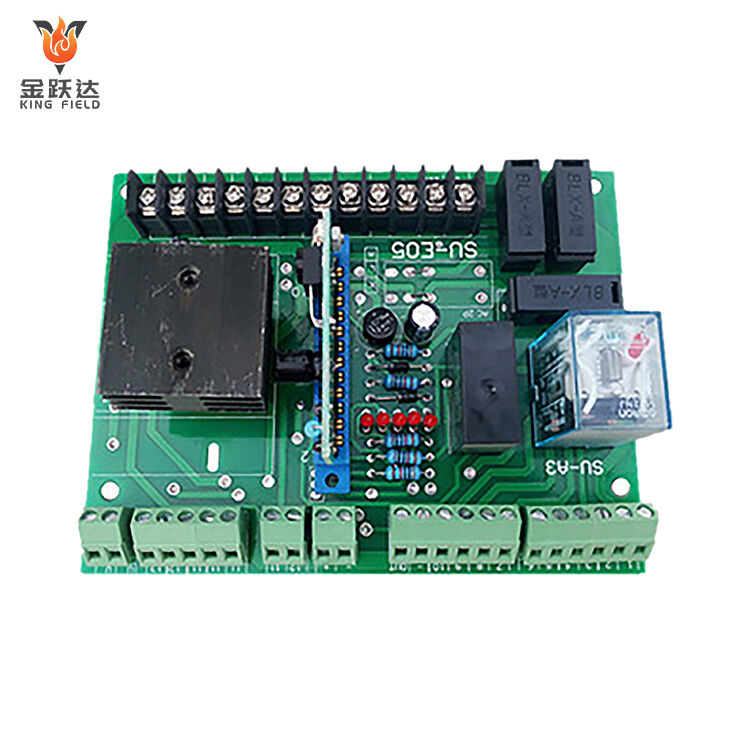

Printed PCBs assembly consist of several critical steps that all require precision and control: solder paste printing, surface mount component placement, reflow soldering, and through-hole assembly when necessary.

If solder paste is applied accurately, joint formation will be perfect. At the same time, pick-and-place equipment of the highest standard ensures that components are positioned correctly. The profiles of reflow soldering must be carefully controlled in order to avoid the occurrence of such defects as cold joints, tombstoning, or solder bridging.

Thanks to the use of automated machines and the setting of process parameters at an optimal level proper standard of consistency and repeatability is maintained by PCB manufacturers like King Field even when it comes to the most complex and densely populated printed PCBs.

Skilled Engineering and Production Teams

In fact, the human factor remains paramount in ensuring the quality of printed PCB assembly although automation has taken a great part in it. The engineers set up the processes, program the equipment, and analyze the defects, whereas the operators are responsible for the stability of daily production.

Well-trained teams have a very good knowledge of their work and can therefore be depended on to quickly recognize irregularities, change parameters, and thus, prevent minor problems from developing into major quality ones. Their experience is also a valuable asset when working with high advanced components, multilayer boards or custom requirements.

King Field’s tech crew is basically a mix of manufacturing on the floor experience and continuously up-to-date theory which totally guarantees a printed PCB assembly of utmost dependability supporting the widest range of applications.

Quality Control and Inspection Systems

One of the pillars of a high-quality PCB printed assembly lies in the effective implementation of quality control. The use of inspection techniques such as solder paste inspection (SPI), automated optical inspection (AOI), X-ray inspection, and functional testing enables the detection of the faults at an early stage.

The purpose of the inspections is to check the soldered joints’ strength, placement of components and also their functionality. Thus, it is less likely that the faulty printed circuit board will be delivered to a customer.

King Field deploys a variety of the inspection methods throughout the process of printed PCB assembly to ensure the compliance with the standards and customers’ requirements.

Process Consistency and Manufacturing Environment

The environmental factor is also one of the major contributors to printed PCB assembly quality. Temperature, humidity, and cleanliness have a direct impact on the quality of soldering and component reliability. Production environments that are stable and controlled prevent oxidation, contamination and moisture-related defects.

Moreover, regular process documentation and uniform operating procedures also help to maintain the same quality level from batch to batch in production.

Conclusion

Printed PCB assembly quality is a result of an intelligent design, top-quality materials, accurate manufacturing processes, properly skilled personnel and well-developed quality control systems. Essentially, they all work together to determine the reliability of the final electronic product.

Outsourcing with a manufacturer with a proven track record such as King Field will allow a business to provide professional knowledge and the latest technological equipment to its customers, together with strict quality management, which in combination will definitely lead to solid, high-quality printed PCB assembly products in today’s highly competitive electronics market.