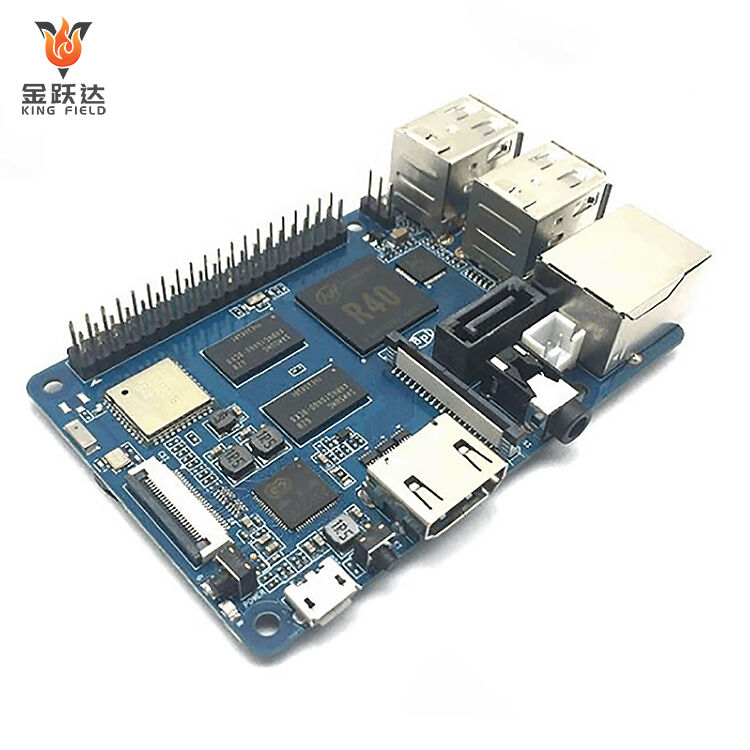

Application of PCBA BGA Assembly In Electronic Industry Processing The PCBA BGA assembly process is considered as one of the major processes to fulfill the dense and high performance circuit board in the production of SMT PCB. Due to the continually shrinking size of electronic devices and increasing functionality, BGA packages are also prevalent in mobiles, industrial controllers, medical devices, and automotive electronics.

Yet, the process of assembling BGA on SMT PCB manufacturing may introduce another level of technical and quality issues that must be prudently managed by a manufacturer.

Visual Inspection: Limited in BGA Assembly

An impediment to PCBA BGA assembly is that the solder joints are hidden beneath the component body. Rather than using pins like conventional packages, BGA solder balls are not able to be visually inspected post reflow. It is making defects detection more difficult in SMT PCB production.

Manufacturers must rely on more sophisticated inspection techniques, such as x-ray inspection (AXI) to identify defects such as voids, solder bridges, and insufficient solder. And without these instruments, latent defects may go undetected and compromise long-term reliability.

Solder Paste Printing Needs to Be Accurate

Precision of solder paste printing is significant in SMT PCB process, and it becomes more challenging for BGA parts with fine pitch and large number of pins. A small change in the volume of paste deposition or misregistration can produce open joints, shorts, or non-uniform solder bonds.

To obtain stability, the PCBA manufacturers need to compensate stencil pattern, aperture size, printing process. This level of accuracy complicates the process, and requires that the engineering control be well practiced.

Challenges of Optimizing Reflow Profiles

The significance of reflow soldering in PCBA BGA assembly is very important. If the temperature profile is too low, it can cause defects such as cold solder joint, bump solder ball collapse or component warpage.

Different BGA package types, PCB materials and solder alloys may require different reflow profiles. In SMT PCB production, the peak temperature, soak time and cooling rate should be integrated to avoid from damaging PCB and sensitive BGA modules.

Thermal Shock and PCB Warpage

Thermal stress can cause PCB warpage in the reflow process of SMT and it is more serious when BGA components are adopted. Even minute board warpage can cause nonuniform solder ball contact, resulting in intermittent connection and early failure.

It is often especially true for high-layer count boards and thin substrates used in advanced PCBA BGA assembly SMT PCB solution. PCB material should be selected and the thermal process should be well controlled to minimize the Warpage in manufacturer.

Challenges in Rework and Repair

With the rest of the SMT parts, rework is a snap compared to BGA rework, you can imagine. Rework BGA and replacing a BGA is three equipment process and you need specialized rework station, precise temperature control and experienced operator.

Excessive rework can tear up the pads, vias, and/or inner layers of the PCB. Remember, it is very important to reduce errors at the beginning of the PCBA BGA assembly process, where expenses are managed and product quality is sustained.

BGA Has Higher Equipment and Skill Needs

Reliable SMT PCB fabrication with BGA packages is a more complex process and requires the use of higher-level equipment such as high precision pick and place machines, X-ray inspection systems, and BGA rework stations.

Also, the engineers must be familiar with the process hands-on This makes the barrier for entry for manufacturers higher, and that means the PCBA partner’s capabilities matter.

Reliability and Duration Issues

BGA solder joints are prone to failure due to thermal cycling and vibrations, particularly in automotive or industrial environments. A poorly controlled PCBA BGA assembly SMT PCB process can cause micro-cracks that may only appear after long-term usage.

Reliability testing, including thermal cycling and vibration testing, is crucial to confirm the validity of SMT PCB assemblies with BGA packages.

Beating the Challenges with the Right Partner

Although PCBA BGA assembly in SMT PCB production has obvious technical difficulty, these difficulties and challenges can be overcome with correct process control, powerful equipment, and experienced engineering teams.

PCBA manufacturing experts such as King Field continuously improve solder paste printing, reflow profiles, inspection processes, and quality management systems to provide more stable and reliable BGA assemblies.

By proactively addressing these challenges, vendors can fully realize the advantages of BGA technology—higher integration, better electrical performance, and smaller form factors—while still meeting the high reliability requirements of today’s electronic products.