Choosing a trusted SMT PCB Assembly Supplier affects quality and delivery in every electronics manufacturing company. SMTA with Surface Mount Technology (SMT) is the essence of the most advanced electronic-products for small, fast, and large-volume end-user electronics products. product result is largely determined by the ability, reliability, and professional provider in the turn-key SMT PCB assembly you choose. A poor choice can lead to delays, defects, increased costs, and even harm to your reputation.

Know the Technical Capabilities of Your Supplier

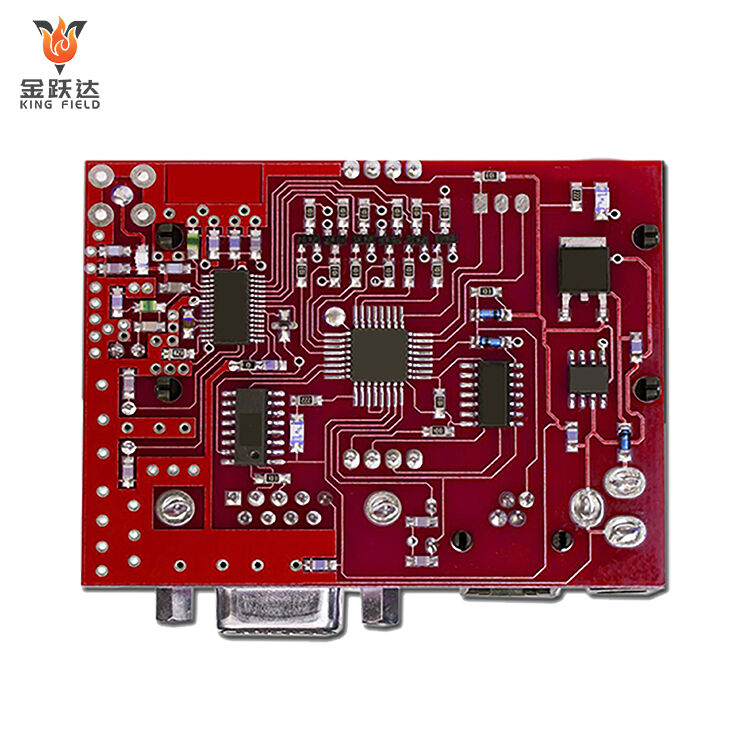

So the first step to find a trustworthy SMT PCB assembly supplier is to analyze its technical power. A professional supplier can provide high-end SMT production lines with high precision pick & place machine, solder paste printer, reflow oven, and AOI systems (Automated Optical Inspection). These instruments guarantee precise component placement and uniform soldering results.

In addition to the equipment, you also want to make sure the manufacturer has the ability to produce your complex PCB design. This is applicable to fine-pitch, BGAs, QFNs, multilayers and mixed technology assemblies (SMT + through-hole). Experienced SMT PCB assembly manufacturers such as King Field typically have superior process deliveries for handling any size project, whether its is prototype or a volume production run.

Assess Quality Control and Certifications

To a certain extent quality assurance is a few real litmus test for authenticity in the SMT PCB assembly provider. Look out for internationally recognized certificates like ISO 9001, ISO 14001 or IATF 16949 (for automotive industry). These certifications mean established and standardized processes and a culture of continuous improvement.

The provider should also have strong process quality controls and traceability on processes including SPI (Solder Paste Inspection), AOI, X-Ray inspection and functional test if required. Ask for the defect rate, the traceability system, and how non conforming products are handled. Reliable suppliers don’t hide quality issues – rather they provide straightforward information and clear remediation paths.

In all processes in King Field, extreme quality management is taken in a process basis in order to keep the stability and reproducibility in SMT PCB assembly.

Review Experience and Industry Specialization

SMT PCB assembly is very much experience-based. A manufacturer who is also a supplier will have more practical knowledge and is more likely to foresee possible issues and improve the processes on their own.

As for the supplier, have a look at their projects and the industries to which they belong. Mereka pernah bekerja dengan produk seperti apa milik Anda? Do they have industrial control, automotive electronics, medical devices, or smart security systems on their list of industries served?

A veteran SMT PCB assembly contractor knows what to expect with industry-specific standards and reliability. Industrial and medical applications may, for instance, require more ruggedness and more testing. For example, King Field has rich experience in many application fields, and it could provide you with real manufacturing solutions rather than simple assembly services.

Evaluate Supply Chain and Parts Availability

A good SMT PCB arrangement manufacturer must have a stable and transparent component supply chain. Component shortages, counterfeit parts, or variable sourcing can wreak havoc on production schedules as well as the reliability of products.

Inquire about the supplier's sourcing for components: do they source from authorized distributors and how do they handle alternative components in the event of shortages?

Turnkey SMT PCB assembly suppliers with great strength usually also provide PCB fabrication service and component procurement service. This all-in-one strategy eliminates the need to manage multiple projects and minimizes risk related to coordination.

Suppliers such as King Field take advantage of proven relationships within supplier networks to deliver guaranteed component authenticity and on-time delivery, regardless of market conditions.

Communications and Engineering Support

Good communication is a quality that’s often overlooked in deciding on an SMT PCB assembly supplier. A trustworthy partner should be quick to reply, clear in communication, and most of all professional in terms of feedback in both the quoting and production stages.

This collaborative way of thinking changes the supplier from a transactional contractor to a long-term manufacturing partner. King Field is well recognized for its engineering-driven philosophy, enabling customers to enhance designs prior to mass production.

Production Capacity and Scalability

Your chosen SMT PCB assembly supplier should be able to meet your needs today and in the future. Think about their capacity, shift work and scalability. Can they handle rush jobs or a surge in demand? Do they have auxiliary lines or contingency plans to 〈minimize〉 downtime?

Reliability is consistency too. A supplier that promises stable quality both for small-batch and mass production manifests that its process management is of a certain level. Companies that are planning product roadmaps over the long term really need this consistency.

Cost Transparency, and Long-Term Value

While price is important, the lowest bid is not always the best. Reliable SMT PCB assembly suppliers have transparent pricing and they can clearly explain what the major cost drivers are in terms of material, labour, testing, and logistics. Latent costs are more likely to become apparent as quality problems or delays that are much costlier.

Think about the long-term value, not just the short-term savings. Improved, consistent quality, less rework, more reliable delivery and more professional support may all add up to lower total cost of ownership over a product's lifetime. Suppliers like King Field strive to establish a healthy balance between competitive price and reliable quality to seek sustainable cooperation rather than one time business transaction.