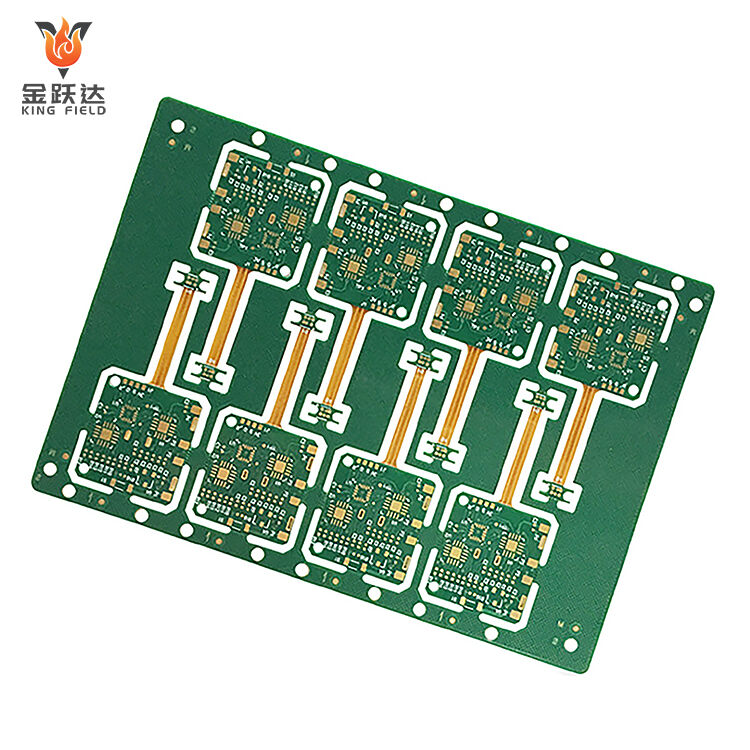

In today's world of electronics, three major factors have been the most important focus points: flexibility, reliability, and high-current handling capabilities.As the devices continue to become smaller while at the same time more powerful and thus, energy demanding, conventional rigid printed circuit boards (PCBs) can hardly meet high-current applications needs. Hence, the introduction of heavy copper flex PCBs to the world of power electronics and high-performance devices. With the ability of heavy copper flex PCBs to carry large currents and at the same time provide much-required flexibility of electronical assemblies in intricate devices, they have become stand-by devices. Here at King Field, it is not a first time that we come across heavy copper flex PCBs helping power electronics and high-performance devices be transformed.

What is Heavy Copper Flex PCB?

Heavy copper flex PCB is essentially a variant of flexible printed circuit board that is characterized with the far thicker copper layer than the usual PCBs.Typically, copper thickness varies from 2 ounces to even more than 10 ounces per square foot. Hence, increasing the copper thickness allows the board to carry more current without overheating or experiencing voltage drops. Indeed, in addition to their high current carrying capacity, flex PCBs are also recognized for their features of, e.g., bending, folding, or twisting which is a contrast with traditional rigid PCBs, thus providing engineers with unlimited design freedom.

Heavy copper in combination with flexible substrates makes a great combination of electrical performance and mechanical flexibility. Therefore, heavy copper flex PCBs are an ideal solution for high-current operation which is very common in the automotive, aerospace, industrial machinery, and renewable energy sectors.

Why Heavy Copper Flex PCB be Chosen for High-Current Applications?

1. Increased Capacity for Current

One major benefit of heavy copper flex PCB is its high current handling ability. A thick copper layer can significantly reduce the film resistance and hence, enable the highest possible current flow with minimum energy waste. As such, it is indispensable in several typical applications such as power distribution modules, motor drives, and high-performance computing where any slight loss of efficiency could result in overheating or failure of the component.

At King Field, we only incorporate the newest technologies in making heavy copper flex PCBs, thus they can carry high current in harsh environments with excellent conductivity, being environmentally friendly at the same time.

2. Superior Heat Dissipation

Current circuits with high power generate a great amount of heat, which depending on the situation, may risk the electronic components. Heavy copper flex PCBs are said to be the best when it comes to heat management, for the copper layers are as thick as the natural heat spreaders. In addition to that, they are capable of heat dissipation at the rate far exceeding regular PCBs, and thus reaching the heat source area is made much easier and the lifetime of the PCB as well as the connected components are extended both.

The above-mentioned thermal benefit is of utmost importance in the electric vehicle industry and renewable energy systems where devices are constantly exposed to high currents at elevated temperatures.The heavy copper flex PCBs manufactured by King Field are driven to give the superior thermal performance of these boards that the problems of overheating are eradicated and the operational stability of the devices is facilitated.

3. Miniaturized and Lightweight

In order to handle a high current similar to the one in a heavy copper flex PCB, a standard high-current PCB ordinarily requires large traces and several layers. The designs thus often turn out to be big, heavy, and stuffed with the components. By utilizing heavy copper flex PCBs, designers will be able to reduce the weight and size without losing the performance.

Situations that are limited in space and super critical in weight such as aerospace, medical, and consumer electronics will greatly profit from such small-size designs. Due to King Field's skills in manufacturing flexible PCBs, we can carry out the production of high-current solutions that not only save space but also retain the material's strength.

4. Extreme Mechanical Flexibility

Unlike rigid boards, heavy copper flex PCBs can be bent, folded, and twisted to make them fit in odd or small places. Such mechanical flexibility can be the wrap of electronic systems with high complexity and tight spaces giving them an extraordinary expansion where the designer's constraints bar the normal rigid boards use. So, with the help of heavy copper flex PCBs, designers can make a device more simple and efficient in terms of layout, reduce the number of connectors and solder joints which will increase the reliability and decrease the production costs.

King Field's sophisticated production techniques allow us to keep the flexibility of our heavy copper flex PCBs even after they have been subjected to high current stress, thus making them perfect for applications involving movement such as robotic systems, wearable gadgets, and automotive control modules.

5. Better Reliability and Long-Life

Generally, high-current operations throw a lot of mechanical stress, vibration, and thermal cycling at PCBs. The mix of heavy copper and flexible substrate gives the final product a higher toughness and a better overall endurance to fatigue. In contrast to regular PCBs, which may crack or delaminate under stress, heavy copper flex PCBs preserve the structural integrity of the board, thereby providing a guarantee of continuous reliable performance even when subjected to harsh environments.

King Field also deeply invests in quality control and testing as vital components of our manufacturing process. We subject our heavy copper flex PCBs to a series of the most stringent electrical and mechanical tests to ensure that they can perform as expected even in high-current and extremely demanding conditions.

Where can Heavy Copper Flex PCB be Utilized?

Heavy copper flex PCBs are highly versatile and, therefore, can be used in the following industries:

- Automotive Electronics: Powertrain control modules, battery management systems, and electric motors in electric vehicles require high-current PCBs with great thermal handling and the ability to last over time.

- Industrial Equipment: Machines of great power, industrial robots, and automated production lines are only some of the applications where heavy copper flex PCB combined compact and flexibility are used.

- Aerospace & Defense:

Reducing weight and increasing reliability are two factors that determine the choice of electronic equipment, making heavy copper flex PCBs very suitable for avionics, satellite, and military electronic applications.

- Renewable Energy Systems:

Components such as solar inverters, power converters, and energy storage units need to be able to withstand high currents and wide temperature fluctuations while still functioning optimally.

- Medical Devices:

Diagnostic apparatuses such as imaging and high-power devices require compact, high-current solutions that are also thermally stable.

King Field’s heavy copper flex PCBs are continuously being used by clients across these sectors, laying down a trustworthy foundation for high-current and high-performance electronic projects.

Reasons to Depend on King Field for Heavy Copper Flex PCB

Having built a reputation for dispensing top-notch PCB solutions, King Field is at the forefront of heavy copper flex PCB design and fabrication. Our portfolio stands proof of our:

- Design custom heavy copper flex PCB to specifically accommodate high-current requirements.

- Manufacture with the most advanced set of equipment to guarantee excellent thermal and electrical efficiency.

- Implement a comprehensive quality control program complemented with brutal testing methods to ensure products' durability and reliability.

- Work in close partnership with clients in order to bring board layouts to the highest level, minimize the complexity of the assembly, and enhance the overall performance of the device.

When you choose King Field, you are choosing to partner with a team that is dedicated to innovating, delivering, and maintaining high-performance PCB solutions that are reliable and capable of meeting the challenges brought by the high-current applications of today.

In the fast-moving electronics market of today, devices are expected to offer more power but at the same time be smaller and more compact. Thus heavy copper flex PCBs produce a number of advantages that other solutions simply cannot match. From the handling of electrical current and heat generation to offering mechanical flexibility and ensuring longer-term reliability, this type of board is really the best choice for high-current usage.

Designers and engineers working with King Field get from us advanced heavy copper flex PCB technology that allows them to create powerful, efficient, and reliable systems for the automotive, aerospace, industrial, renewable energy, and medical industries. When the need to handle high currents and the problem of limited space coincide, heavy copper flex PCBs certainly are the answer, rather than just an alternative.