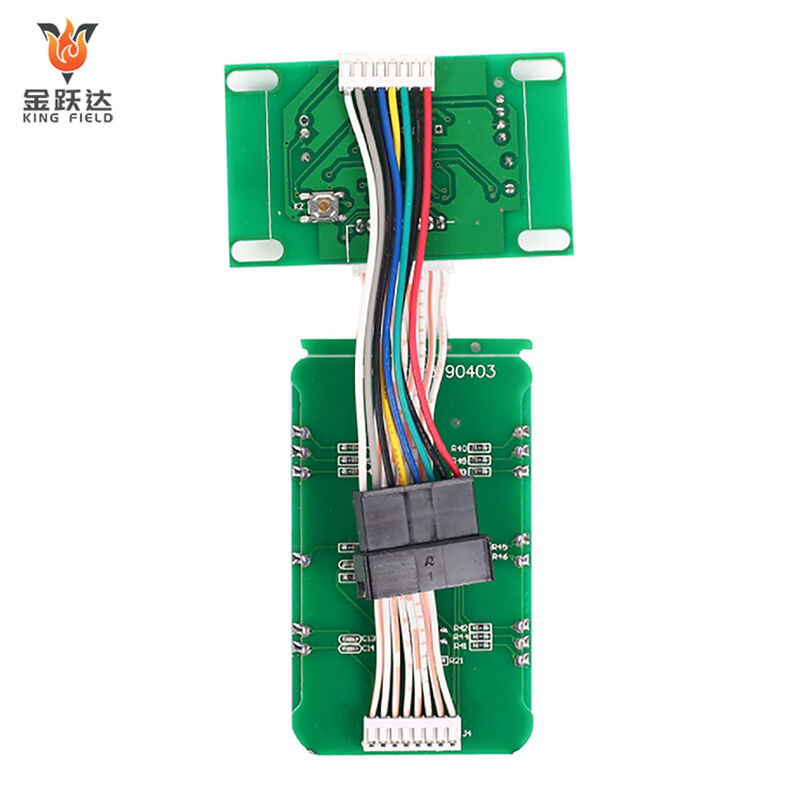

Wire Harness Assembly

Custom Wire Harness Assembly for medical, industrial, automotive & consumer electronics. Precision-engineered with premium wires, connectors, and protective sleeving—optimized for stable signal/power transmission and durability in harsh environments.

Compliant with UL, IEC, ISO & automotive IATF 16949 standards, our harnesses undergo strict crimping, soldering, and continuity testing. 24h prototyping, fast delivery, and DFM support enable seamless scaling from R&D to mass production, tailored to your device’s unique layout and performance needs.

Description

Wire Harness Assembly

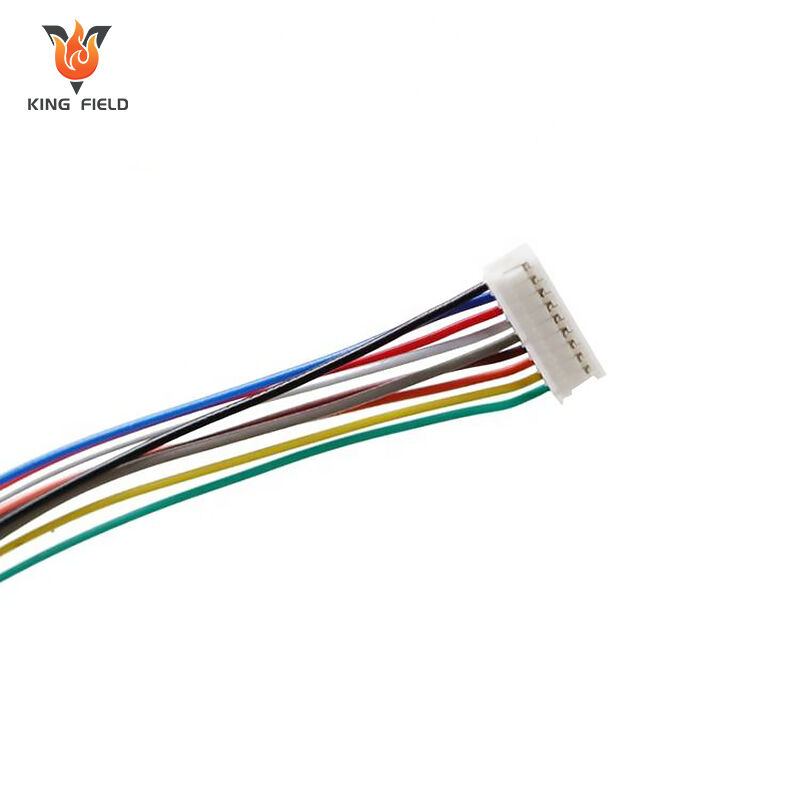

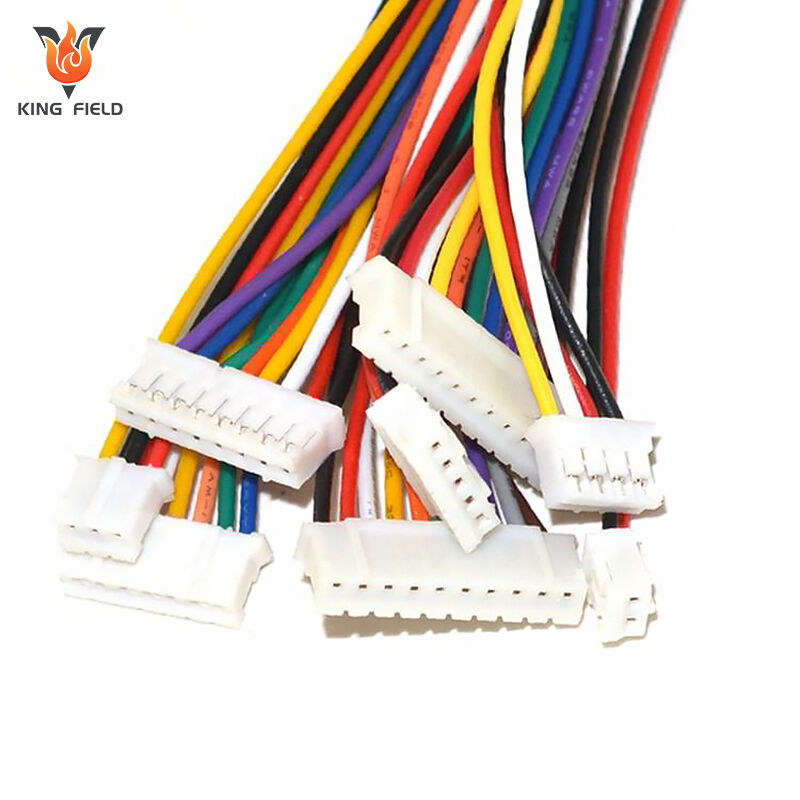

Wire Harness Assembly is a pre-integrated system of insulated wires/cables, connectors, terminals, and protective components that are bound together to transmit power or signals in equipment.By consolidating multiple wires into a single harness, manufacturers can streamline installation, improve organization, and enhance the overall reliability of electrical systems.

Whether you’re in the automotive industry, aerospace, or consumer electronics, understanding wire harness assemblies is essential for creating robust and efficient electrical systems. This comprehensive guide will delve into the world of wire harness assemblies, exploring their types, benefits, design processes, and manufacturing techniques.

Core Features:

Integration & Standardization: Organizes scattered wires into a unified, structured assembly, replacing messy individual wiring to simplify installation and reduce errors.

Customization: Tailored to specific equipment requirements for industries like automotive, medical, industrial control, and consumer electronics.

Protection: Includes insulation, abrasion resistance, and EMI shielding to ensure reliability in harsh environments .

Key Applications:

Automotive: Used in engine compartments, infotainment systems, and chassis for power/signal transmission.

Medical Devices: Ensures safe, stable connections in diagnostic equipment, surgical tools, and patient monitors.

Industrial Control: Integral to PLCs, robotics, and factory automation systems, withstanding high vibration and temperature fluctuations.

Consumer Electronics: Found in home appliances, smart devices, and audio-visual equipment for compact, reliable wiring.

Custom wiring harnesses are categorized based on application industry, structural design, performance requirements, and installation environment. Below is a structured breakdown of key types, aligned with your core industries:

By Application Industry

· Automotive Wiring Harnesses

Subtypes: Engine harnesses, chassis harnesses, body harnesses, infotainment harnesses, EV/hybrid high-voltage harnesses.

Key Features: Compliant with automotive standards (ISO 19642, IATF 16949), resistant to high temperatures, vibration, oil, and moisture; high-voltage harnesses require EMI shielding and insulation safety.

· Medical Wiring Harnesses

Subtypes: Diagnostic equipment harnesses (MRI/CT scanners), surgical tool harnesses, patient monitor harnesses, wearable medical device harnesses.

Key Features: Meet medical-grade standards (ISO 13485, FDA requirements), biocompatible materials, sterilization resistance (autoclave/ethylene oxide), low electromagnetic interference (EMI) to avoid disrupting sensitive equipment.

· Industrial Control Wiring Harnesses

Subtypes: PLC system harnesses, robotic arm harnesses, factory automation (FA) equipment harnesses, sensor/actuator connection harnesses.

Key Features: High durability for harsh industrial environments, anti-interference (shielded cables), compliance with IEC 60335, UL 508.

· Consumer Electronics Wiring Harnesses

Subtypes: Home appliance harnesses, smart device harnesses (IoT sensors, smart home controllers), audio-visual equipment harnesses.

Key Features: Compact design, cost-effective, lightweight, compliant with UL 1581, RoHS; optimized for space-saving in small devices.

By Structural Design

Single-Wire Harnesses: Simple structure with individual wires bundled together.

Multi-Branch Harnesses: Complex routing with multiple branches/connectors.

Flat Cable Harnesses: Uses flat ribbon cables (FRC) for compact, high-density connections.

Coaxial Cable Harnesses: Integrates coaxial cables for high-frequency signal transmission.

By Performance Requirements

High-Voltage Harnesses: For 600V+ applications with reinforced insulation and shielding.

Low-Voltage Harnesses: For <600V focusing on signal integrity.

Heat-Resistant Harnesses: Uses high-temperature materials (PTFE, silicone) for engine compartments, industrial furnaces.

Waterproof Harnesses: IP67/IP68 rated with sealed connectors and protective sleeves.

EMI/RFI Shielded Harnesses: Wrapped in metal foil/braided shielding to block electromagnetic interference (medical imaging, industrial robotics).

By Installation Environment

Indoor Harnesses: Protected environments (consumer electronics, medical device interiors) – focus on compactness and cost.

Outdoor/Harsh Environment Harnesses: Exposed to weather, chemicals, or physical stress– prioritizes durability and protection.

Wire Harnesses vs. Cable Assemblies

Wire Harnesses vs. Cable Assemblies

Wire Harnesses and Cable Assemblies are both pre-integrated wiring solutions, but they differ in structure, design purpose, and application scenarios. Below is a clear comparison to distinguish the two, aligned with your core industries:

Core Definitions

Wire Harness: A collection of individual insulated wires/cables bound together (via tape, sleeves, or looms) with connectors/terminals, designed for organized routing of power/signal in equipment. Wires remain separate inside the bundle (no permanent bonding).

Cable Assembly: A finished unit using multi-conductor cables with connectors/terminals, often including shielding, jackets, or strain relief. The conductors are pre-integrated into a single cable jacket.

Key Differences

| Aspect | Wire Harness | Cable Assembly | |||

| Structure | Individual wires bundled together | Multi-conductor cables in a single jacket (permanent integration) | |||

| Flexibility | High flexibility (wires can be routed independently in branches) | Lower flexibility (fixed cable structure) | |||

| Complexity | Supports complex multi-branch routing | Simple linear or fixed configurations | |||

| Protection | Basic (tape, sleeves for individual wires) | Enhanced (integrated shielding, rugged jackets for entire cable) | |||

| Cost | Lower for custom multi-branch designs | Lower for high-volume standard configurations | |||

| Space Efficiency | Less compact (bulkier bundles) | More compact (single jacket) | |||

Industry-Specific Applications

· Automotive

Wire Harnesses: Engine harnesses, chassis harnesses, body harnesses (multi-branch routing to connect lights, sensors, and modules).

Cable Assemblies: EV charging cables, infotainment system coaxial cables (fixed-length, shielded for high-frequency signals).

· Medical

Wire Harnesses: Patient monitor internal wiring (multi-branch connections to sensors/display).

Cable Assemblies: MRI scanner power cables, surgical tool data cables (rugged, shielded to avoid EMI).

· Industrial Control

Wire Harnesses: PLC cabinet wiring (multi-branch connections to I/O modules, actuators).

Cable Assemblies: Robotic arm Ethernet cables, sensor connection cables (fixed-length, abrasion-resistant).

· Consumer Electronics

Wire Harnesses: Washing machine internal wiring (branching to motors, valves, controls).

Cable Assemblies: USB-C charging cables, TV HDMI cables (standardized, high-volume).

When to Choose Which?

Wire Harness: For equipment requiring custom multi-branch routing, frequent modifications, or connection to multiple components (e.g., industrial automation systems, automotive interiors).

Cable Assembly: For fixed-length, standardized connections, high-frequency signal transmission, or harsh environments requiring robust shielding/jacketing .

Benefit

Wire Harness Assembly delivers significant value across industries by solving wiring challenges and optimizing system performance. Below is a structured breakdown of core benefits, aligned with your business focus:

Enhanced Reliability & Reduced Failure Risk

Eliminates loose wires, incorrect connections, and short circuits (common with ad-hoc wiring) through standardized design and factory testing (continuity, insulation, voltage checks).

Protective components resist environmental stress, critical for automotive undercarriages, industrial factory floors, and medical device sterilization cycles.

Complies with industry standards (IATF 16949 for automotive, ISO 13485 for medical, UL 508 for industrial) to ensure safety and consistency.

Simplified Installation & Reduced Labor Costs

Pre-assembled harnesses replace on-site wiring, cutting installation time by 50%+.

Clear labeling and standardized connector interfaces eliminate guesswork, reducing human error and training requirements for technicians.

Compact, organized design fits into tight spaces without compromising accessibility.

Improved System Performance & Signal Integrity

Shielded harnesses block EMI/RFI interference, critical for medical imaging devices (MRI/CT scanners), industrial robotics, and automotive infotainment systems.

Custom wire gauges, lengths, and routing optimize power transmission efficiency and signal accuracy.

Reduced wire clutter minimizes electromagnetic cross-talk, ensuring stable operation of sensitive components.

Scalability & Customization for Industry Needs

Tailored to specific equipment requirements.

Mass-producible with consistent quality for large-scale projects while supporting low-volume custom designs.

Easy to integrate with existing systems, enabling seamless upgrades.

Simplified Maintenance & Troubleshooting

Modular design allows quick replacement of damaged harness sections (no full system rewiring), reducing downtime for industrial machinery and medical equipment.

Clear documentation and labeling speed up fault diagnosis.

Long service life (often matching equipment lifespan) reduces replacement frequency and total cost of ownership (TCO).

Space & Weight Optimization

Consolidated wiring reduces bulk and weight (critical for EVs, aerospace, and portable medical devices), improving energy efficiency and portability.

Neat routing maximizes usable space in compact enclosures.

Industry-Specific Benefits

| Industry | Unique Advantages | ||||

| Medical | Sterilization resistance, biocompatibility, EMI shielding for sensitive diagnostics | ||||

| Industrial Control | Vibration/chemical resistance, quick maintenance for factory downtime reduction | ||||

| Automotive | High-temperature/oil resistance, compliance with automotive safety standards | ||||

| Consumer Electronics | Compact design, cost-effectiveness, RoHS compliance for global markets | ||||

Production Capacity

| Assembly Types |

● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

||||

| Quality Inspection |

● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

||||

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB | ||||

| Component Types |

● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

||||

| Components Sourcing |

● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

||||

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste | ||||

| Order quantity |

● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

||||

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready | ||||