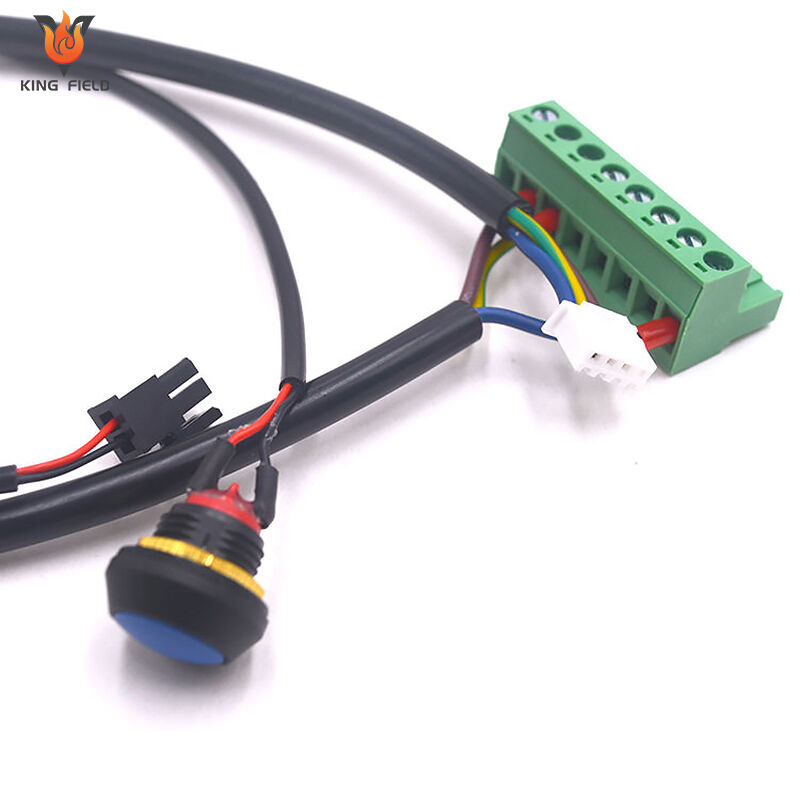

Cable Assembly

High-reliability Cable Assembly solutions for medical, industrial, automotive & consumer electronics. Custom-engineered wiring harnesses, power cables, and signal cables—built with premium materials, precise crimping/termination, and strict quality testing.

Compliant with industry standards (UL, IEC, ISO), our cable assemblies ensure stable signal transmission, durability in harsh environments, and seamless integration with your devices. 24h prototyping, fast delivery, and DFM support scale from R&D to mass production.

✅ Custom wiring harnesses & cable designs

✅ Industry-standard compliance

✅ Harsh environment resistance

Description

What is a Cable Assembly?

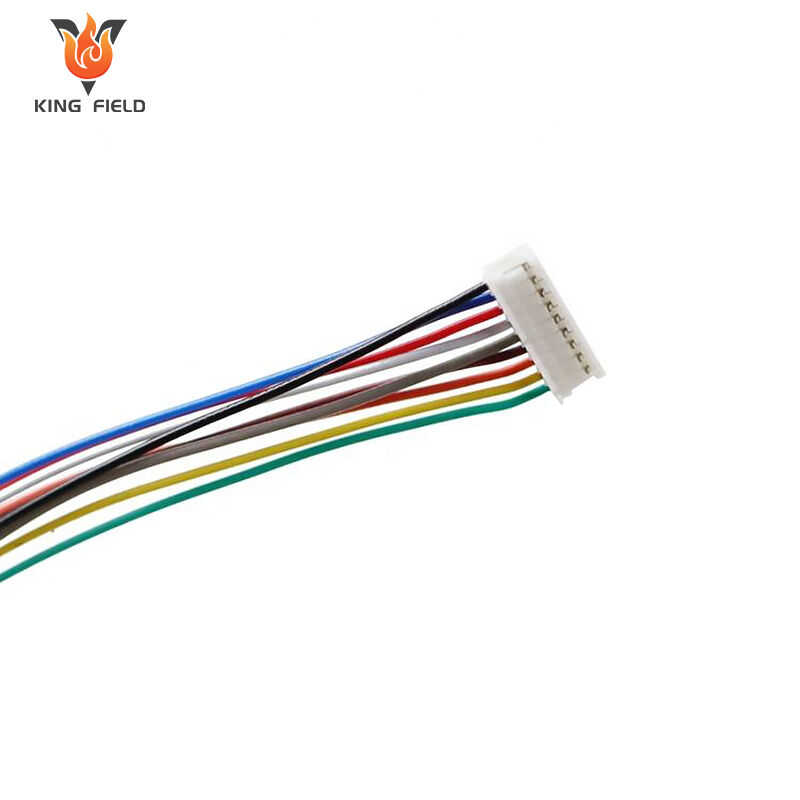

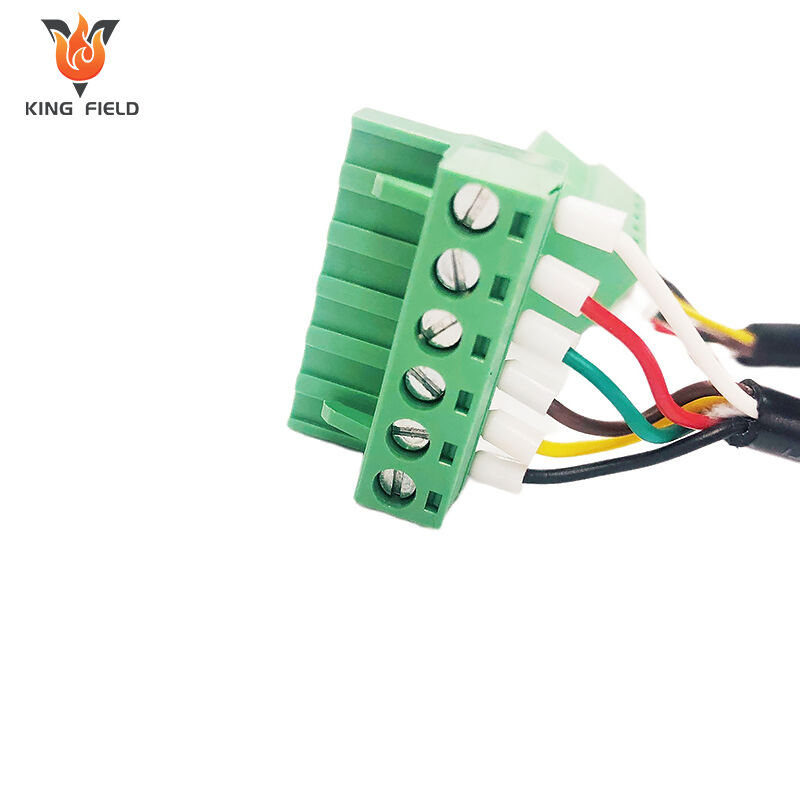

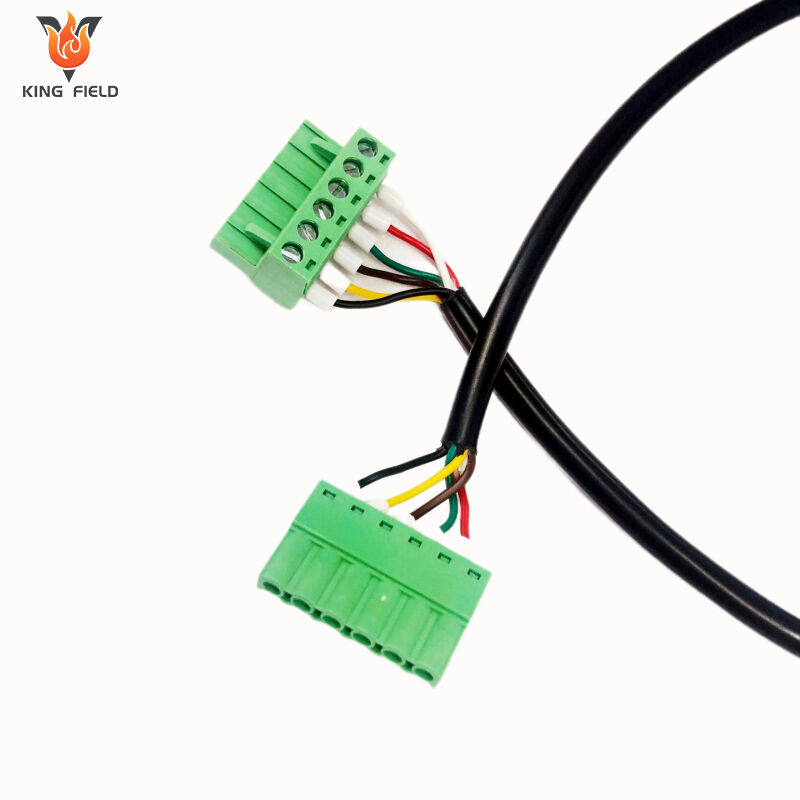

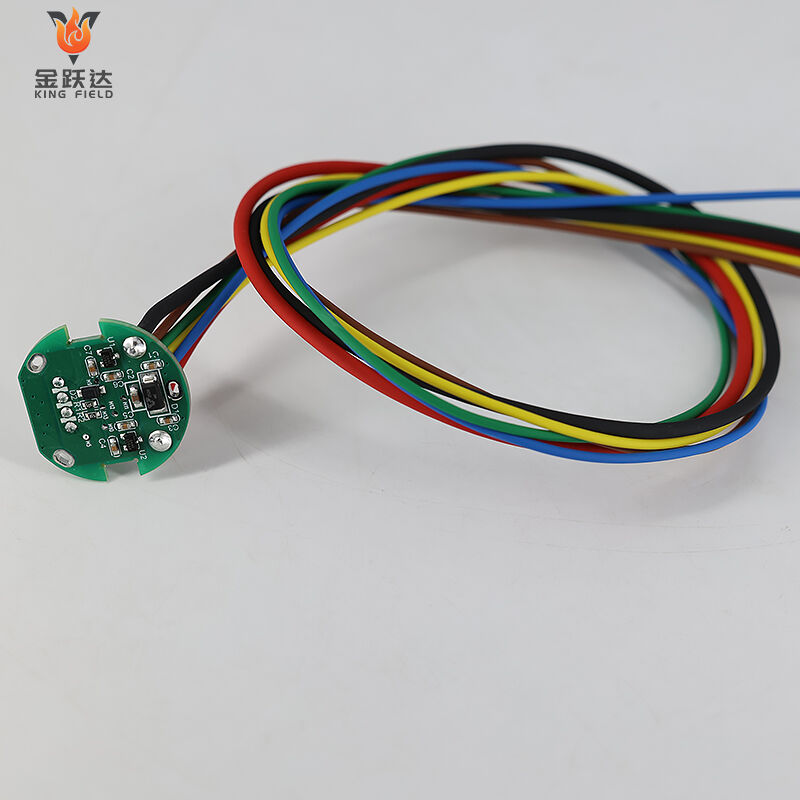

A cable assembly is a standardized, prefabricated transmission unit made by cutting, crimping, welding, assembling, and testing one or more cables and matching connectors, terminals, sheaths, shielding layers, and other components. Its core function is to realize the transmission of electrical signals or power between devices and systems. Unlike a simple "cable" or "connector", it is a transmission solution with complete functions.

Cable assemblies can be classified according to core dimensions such as transmission purpose, structural characteristics, application scenarios, and performance requirements. The specific types and characteristics under different classification dimensions are as follows:

Classification by Transmission Purpose

| Type | Core Functions | Technical features | Typical applications | ||

| Power cable assembly | Transmitting electrical energy (high voltage) | Large wire diameter, high current carrying capacity, and high voltage withstand rating | New energy vehicle battery power supply cable, industrial equipment power supply cable, charging pile cable | ||

| Signal cable assembly | Transmitting data/control signals (low voltage) | Thin wire diameter, emphasis on signal integrity, some parts are shielded | USB data cable, HDMI cable, Ethernet (RJ45) cable, PLC control connection cable | ||

| RF cable assembly | Transmitting high-frequency radio frequency signals (3kHz~300GHz) | Low loss, impedance matching (50Ω/75Ω), high shielding | Base station radio frequency connection cable, radar signal transmission line, satellite communication feeder cable | ||

| Hybrid cable assembly | Simultaneous transmission of power + signal/radio frequency | Integrates multiple types of cables, with a compact structure. | Industrial robot cables (power supply + control signal), vehicle-mounted camera cables (power supply + video signal) | ||

Classification by structure and shielding characteristics

| Type | Structural features | Advantages | Applicable Scenarios | ||

| Unshielded cable assembly | Unshielded, contains only cable and connector. | Low cost and good flexibility | Indoor low-interference environment | ||

| Shielded cable assembly | Contains copper mesh/aluminum foil/double shielding layer | Strong resistance to electromagnetic interference (EMI) | Industrial control, radio frequency transmission, automotive electronics (engine compartment) | ||

| Single-core cable assembly | Only a single conductor core wire | Simple structure and high pressure resistance | High-voltage power transmission | ||

| Multi-core cable assembly | Multiple independent core wires integrated (2 to hundreds of cores) | Highly integrated, capable of transmitting multiple signals simultaneously. | Industrial equipment control lines, automotive wiring harnesses, medical equipment connection lines | ||

| Flexible cable assembly | Highly flexible cable (resistant to bending) is used. | Resistant to repeated bending (over one million cycles) | Industrial robots, cable chain equipment, flexible production lines | ||

| coaxial cable assembly | Coaxial structure consisting of core wire + insulation layer + shielding layer + outer sheath | Low high-frequency transmission loss and stable impedance | Radio frequency communication, cable TV lines, base station feeders | ||

Classified by application scenario

| Type | Environmental Adaptation Requirements | Key features | Typical products | ||

| Consumer electronics cable assemblies | Lightweight, standardized, low cost | Universal interface (USB/Type-C/HDMI) | Mobile phone charging cable, headphone cable, monitor connection cable | ||

| Industrial control cable assemblies | Resistant to high and low temperatures (-20℃~85℃), vibration resistant, and oil resistant. | High shielding, bend resistance, and high protection rating (IP65+). | Servo motor cable, sensor connection cable, PLC communication cable | ||

| Automotive cable assemblies | Resistant to high and low temperatures (-40℃~125℃), oil-resistant, aging-resistant, and waterproof. | Flame retardant, low smoke and halogen-free, and resistant to electromagnetic interference | Vehicle battery harness, radar connection cable, body control cable | ||

| Aerospace cable assemblies | Lightweight, radiation resistant, and highly reliable | High temperature resistance (-55℃~200℃), low gas exudation | Aircraft avionics system cables, satellite communication cables | ||

| Medical equipment cable assemblies | Sterile, corrosion-resistant, and with low electromagnetic interference | Good biocompatibility and can be disinfected | Monitor connection cable, surgical instrument cable, imaging equipment data cable | ||

| Outdoor/Waterproof Cable Assembly | Waterproof, dustproof, and UV resistant | Protection rating IP67/IP68, sheath is resistant to aging. | Security camera cables, outdoor base station power cords, marine equipment cables | ||

Classification by connector type

| Connector type | Cable assembly features | Application scenarios | |||

| USB cable assembly (Type-A/C/Micro) | Plug and play, data and power compatible | Consumer electronics, mobile devices | |||

| Circular connector cable assembly (aviation plug) | Waterproof, vibration resistant, and with a strong connection | Industrial equipment, outdoor equipment, military products | |||

| RJ45 cable assembly | Standardized Ethernet interface for data transmission | Computer networks and monitoring systems | |||

| RF connector cable assembly (SMA/N/BNC) | High frequency, low loss, and precise impedance matching | Communication base stations, testing instruments, radar | |||

| Fiber optic connector cable assemblies (LC/SC/FC) | Transmitting optical signals, with large bandwidth and extremely low loss | High-speed data centers and long-distance communications | |||

Manufacturing capabilities

Manufacturing capabilities

| Assembly Types |

● SMT Assembly( with AOI inspection); ● BGA Assembly(with X-Ray inspection); ● Through-hole Assembly; ● SMT & Through-hole Mixed Assembly; ● Kit Assembly |

||||

| Quality Inspection |

● AOI Inspection; ● X-Ray Inspection; ● Voltage Test; ● Chip Programming; ● ICT Test; Functional Test |

||||

| PCB Types | Rigid PCB、Metal core PCB、Flex PCB、Rigid-Flex PCB | ||||

| Component Types |

● Passives, smallest size 0201(inch) ● Fine-pitch chips to 0.38mm ● BGA (0.2mm pitch), FPGA, LGA, DFN,QFN with X-Ray testing ● Connectors and terminals |

||||

| Components Sourcing |

● Full turnkey (All components sourced by Yingstar); ● Partial turnkey; ● Kitted/Consigned |

||||

| Solder Types | Leaded; Lead-Free(Rohs);Water soluble solder paste | ||||

| Order quantity |

● 5pcs to 100,000pcs; ● From Prototypes to Mass Production |

||||

| Assembly Lead Time | From 8 hours to 72 hours when parts are ready | ||||