Smaller is no longer synonymous with weaker in the electronics market of nowadays. Manufacturers, from wearable devices and smartphones to medical instruments and industrial control systems, are expected to provide compact products with higher speed, greater stability, and more functions than ever. This requirement has led HDI PCB electronics manufacturing to the leading edge of advanced circuit design and production.In a way, HDI PCBs are essential contributors to how well miniaturized electronic devices work, as they allow for higher circuit density, better signal integrity, and improved thermal management.

Understanding HDI PCB Electronics Manufacturing

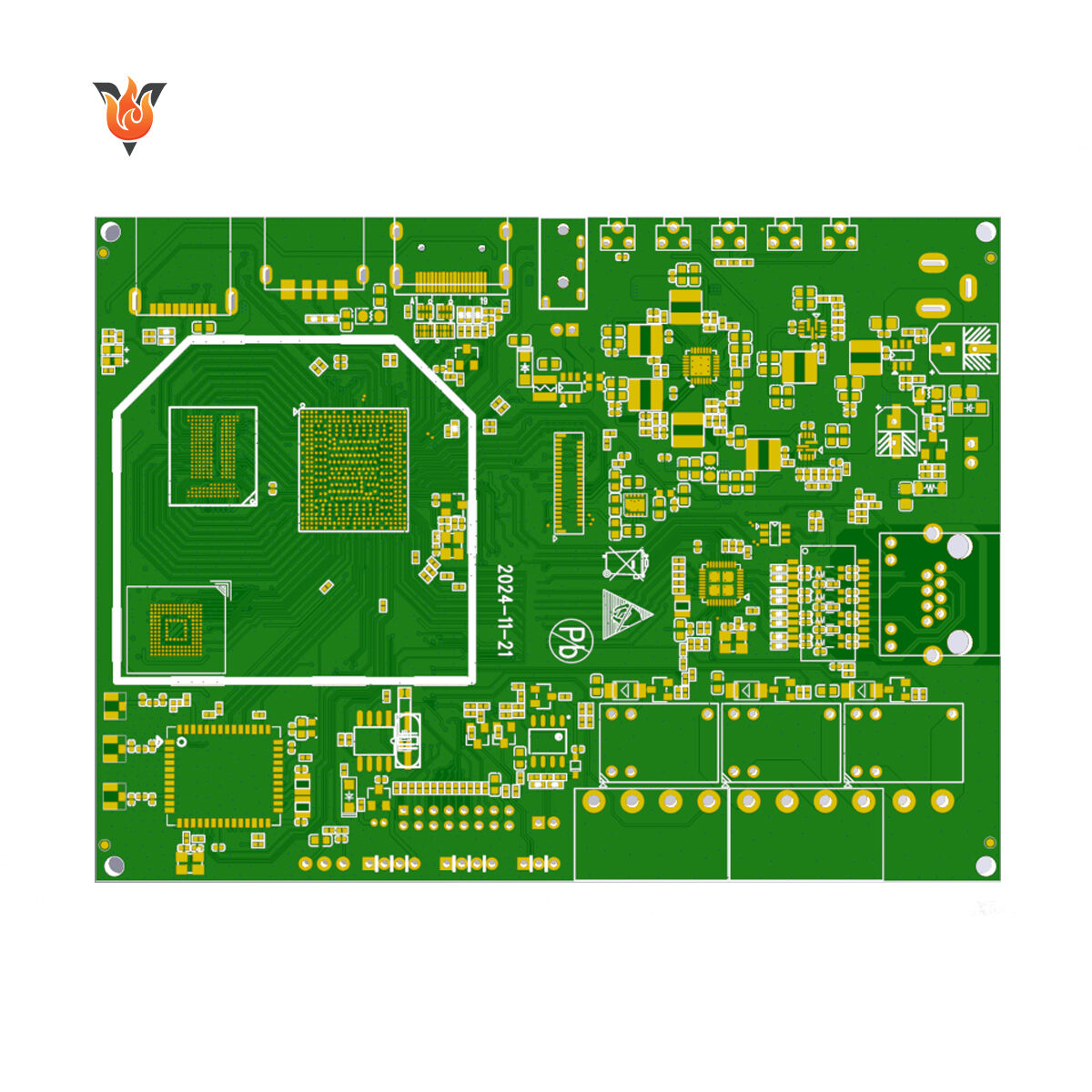

HDI is an acronym for High-Density Interconnect, which is a term that describes printed circuit boards decorated with features like microvias, blind and buried vias, fine line widths, and multilayer stacking.Unlike regular PCBs, HDI boards allow the components to be placed densely in a compact area without compromising the electrical reliability.

HDI PCB electronics manufacturing is not only about downsizing a mother-board but also includes accurate engineering, strict process control, and the use of special equipment to assure flawless interconnections even under the harshest conditions of use.

Achieving Higher Circuit Density for Smaller Devices

One of the main advantages of HDI PCB electronics manufacturing is that it can result in a very high circuit density. Microvias are used instead of the traditional through-holes, which gives designers the freedom to most accurately route signals between layers. Therefore, this means:

- Components can be packed closer together

- Shorter signal paths lead to lower electric loss

- The smaller the board size, the easier it is to have a compact product design

For microscopic devices, small units like millimeters really matter. Thanks to HDI PCBs, numerous different functions—processing, communication, sensing, and power management—can all be put together on one tiny board without any loss of performance.

Better Signal Integrity and Electrical Performance

Signal integrity is one of the first things that take a hit when we try to reduce the size of devices and, at the same time, increase their speed.A long trace and too many vias may result in signal reflection, crosstalk, and electromagnetic interference. HDI PCB electronics manufacturing counters these problems by the use of:

- Shorter and more direct routing paths

- Controlled impedance design

- Reduced parasitic capacitance and inductance

The above-mentioned improvements mostly matter for high-speed digital signals, RF applications, and data-intensive electronics that constantly require clean signal transmission. HDI PCBs facilitate miniaturized devices to run at higher speeds and with better reliability.

Heat Management is Critical in Miniaturization

Miniaturization is most of the time a synonym for increased heat density. Too much heat unfavorably affects a product’s performance or could cause the shortening of the product’s lifespan. HDI PCB electronics manufacturing offers solutions for heat control such as:

- Layer stack-ups that are optimized in terms of dissipating heat

- Placement of thermal vias next to the components that generate most of the heat

- Better copper distribution to spread and release heat

Thanks to efficient heat management, HDI PCBs enable compact devices to remain stable even when they have been operating under continuous or high-load conditions.

Superior Reliability Through Modern Interconnection Techniques

In the case of medical electronics, automotive systems, and industrial automation sectors, reliability has always been a serious issue. One of the ways by which HDI PCB electronics manufacturing contributes to increasing reliability is by eliminating the sources of mechanical stress. Microvias, as compared to conventional vias, are smaller and sturdier, and the multilayer interconnections are capable of withstanding vibration, temperature changes, and long-term use.

King Field, for example, maintain rigorous quality control standards through all stages of the HDI production process, from choosing materials to conducting the final inspection. It is through these that each HDI PCB is not only able to meet high reliability requirements but also supports complex miniaturized designs.

Allowing Advanced Functions and Integration

The are various ways through which HDI PCB electronics manufacturing can help is to enable advanced integration, such as:

- Fully integrated system-in-package (SiP) designs

- Support for high pin-count ICs

- Mixed-signal and high-frequency integration

Thanks to these features, designers are able to put different subsystems on a single board, thus, eliminating the need for connectors and extra wiring. Hence, one obtains a product that is smaller, lighter, and more efficient and that contains very few points of failure.

It is the Know-How of the Factory That Makes the Difference

Although the HDI technique directly presents several benefits, to a great extent, its success depends on the manufacturing know-how. Reliable HDI PCBs can only be produced through precision drilling, accurate lamination, and consistent plating. King Field, a seasoned manufacturer, is well-versed in all the ins and outs of HDI PCB electronics manufacturing processes and so can guide customers in making a trade-off between performance, cost, and scalability.

Collaborative works in various stages of the design help the manufacturer determine optimal stack-up structures, via configurations, and material choices which, in turn, makes the performance of miniaturized devices that much higher.

Final Remarks

The production of HDI PCBs is a critical factor that makes high-performance miniaturized devices possible. It is by means of greater circuit density, enhanced signal integrity, superior thermal management, and improved reliability that, nowadays, electronics are being made smaller, more robust, and more powerful. As the electronics sectors are continuously striving to break the barriers of miniaturization, cooperating with companies that have a lot of experience like King Field will guarantee that the most advanced HDI technologies will be converted into performance advantages in the real world.