Introduction

In today’s world of high-density electronics, the demand for reliable, compact, and electrically robust circuit boards continues to rise. The 4-layer PCB, sometimes called a four-layer printed circuit board, has become one of the most widely adopted solutions for applications ranging from consumer IoT devices to industrial control systems and automotive electronics.

While two-layer PCBs might suffice for simple circuits, technology trends like higher clock rates, mixed-signal design, and compact device footprints require improved signal integrity, lower electromagnetic interference (EMI), and better power distribution—benefits all delivered by 4-layer PCB stackups.

This comprehensive guide from kingfield—your trusted Shenzhen PCB manufacturer and UL, ISO9001, ISO13485 certified supplier—will walk you through:

- The construction and function of a 4-layer PCB.

- Detailed, step-by-step 4-layer PCB manufacturing processes.

- Stack-up concepts, inner layer etching and lamination practices.

- Best practices for design (signal, power, and ground plane arrangement, controlled impedance, via management) and downstream assembly.

- The technologies behind drilling (CNC), via plating and electroplating, solder mask selection and curing, and surface finishes such as ENIG, OSP, and HASL.

- Key QC and testing standards like AOI and in-circuit test (ICT).

- How to mesh material preparation, process flow, and stack-up optimization for quality, cost-effectiveness, and performance.

What is a 4 Layer PCB?

A 4-layer PCB (four-layer printed circuit board) is a type of multilayer PCB that contains four stacked layers of copper conductors, separated by layers of insulating dielectric material. The core idea behind a 4-layer PCB stackup is to provide designers with more freedom and reliability for routing complex circuits, achieving controlled impedance, managing power distribution, and minimizing EMI compared to traditional 2-layer PCBs.

Construction and Typical Layer Stack-Up

A conventional 4-layer PCB is fabricated by laminating alternating layers of copper and dielectric (also known as prepreg and core) to achieve a rigid, flat structure. The layers typically represent the following functions:

|

Layer

|

Functionality

|

|

Top Layer (L1)

|

Signal routing, component pads (commonly SMT/THT)

|

|

Inner Layer 1 (L2)

|

Usually ground plane (GND) for signal integrity and EMI

|

|

Inner Layer 2 (L3)

|

Typically power plane (VCC, 3.3V, 5V, etc.)

|

|

Bottom Layer (L4)

|

Signal routing, SMT components or connectors

|

This arrangement (Signal | Ground | Power | Signal) is the industry standard and provides several engineering benefits:

- Signals on the outside make assembly and troubleshooting easier.

- Solid ground plane under high-speed traces reduces EMI and crosstalk.

- Dedicated power plane results in robust power delivery and optimal bypassing.

4-Layer PCB vs. Other PCB Types

Let’s compare key attributes among typical PCB configurations:

|

Feature

|

2-Layer PCB

|

4-Layer PCB

|

6-Layer PCB

|

|

Number of Copper Layers

|

2

|

4

|

6

|

|

Routing Density

|

Low

|

Moderate/High

|

Very High

|

|

Signal Integrity

|

Limited

|

Excellent (if well-designed)

|

Superior

|

|

Power Delivery

|

Basic (no planes)

|

Strong (dedicated plane)

|

Excellent (multiple planes)

|

|

EMI Reduction

|

Minimal

|

Good

|

Best

|

|

PCB Thickness

|

0.8mm–2.4mm

|

1.2mm–2.5mm (typical)

|

1.6mm+

|

|

Application Range

|

Low-density, Simple

|

Med-high complexity

|

High-frequency, critical SI

|

|

Cost

|

Low

|

Medium (≈2× 2-layer)

|

High

|

Key Advantages of 4-Layer PCBs

1. Enhanced Signal Integrity

A four-layer PCB design offers tightly controlled trace impedance and a short, low-inductance signal return path—thanks to internal reference planes. This is particularly important for high-speed or RF signals, such as those in USB 3.x, HDMI, or wireless communications. The use of a continuous ground plane directly under signal layers significantly reduces noise, crosstalk, and risk of signal distortion.

2. EMI Reduction

EMI is a major concern in modern electronics. The multi-layer stack-up design—including ground and power planes in close proximity—acts as an inherent shield against external noise and prevents radiation from the board's own high-speed circuits. Designers can fine-tune plane spacing (prepreg/core thickness) for best EMC results.

3. Superior Power Distribution

The internal power and ground planes form a natural power distribution network (PDN) and provide a large area for decoupling capacitors, reducing voltage drops and power supply noise. They help balance heavy load currents and prevent hotspots that can damage sensitive components.

4. Increased Routing Density

With two extra copper layers available, circuit designers have much more room to route traces—reducing reliance on vias, shrinking board sizes, and making it possible to handle more complex devices (such as LSI, FPGAs, CPUs, and DDR memories).

5. Practical for Smaller Devices

4-layer PCB stackups are ideal for compact or portable electronics, including IoT sensors, medical instruments, and automotive modules, where tighter layouts are vital for product form factor.

6. Better Mechanical Strength

The structural rigidity provided by multi-layer lamination ensures the PCB can withstand assembly stress, vibration, and flexing experienced in harsh environments.

Typical 4-Layer PCB Usage Scenarios

- Routers, home automation, and RF modules (better EMC and signal performance)

- Industrial controllers and automotive ECUs (resilience and reliability)

- Medical devices (compact footprint, noise-sensitive signals)

- Smartwatches and wearables (high-density, small form factor)

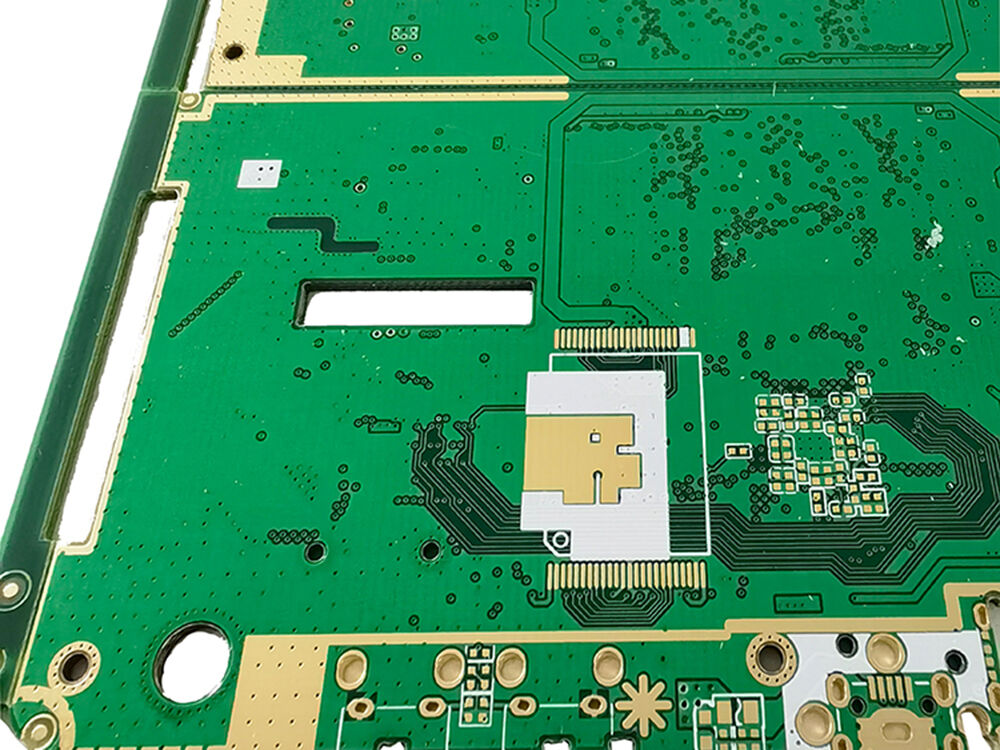

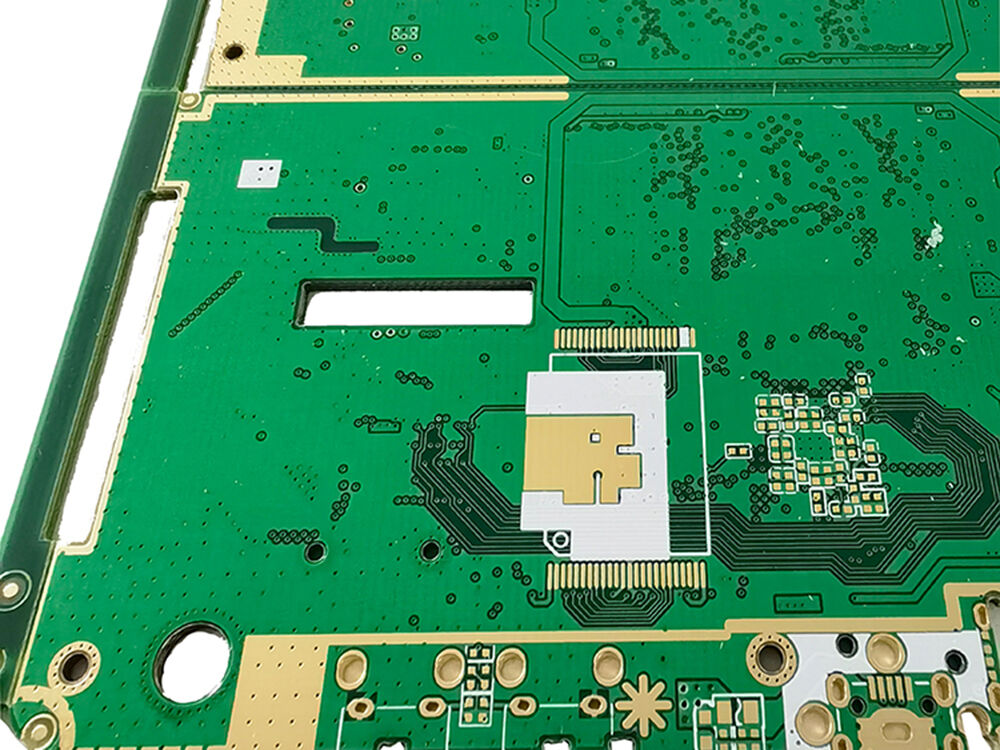

Key steps in the 4-layer PCB manufacturing process

Understanding the manufacturing process of a 4-layer PCB step by step is crucial for anyone involved in PCB design, procurement, or quality assurance. At its core, four-layer PCB fabrication is a precision-driven, multi-stage process that transforms raw copper-clad laminates, prepreg, and electronic design files into a robust, compact, ready-to-assemble multilayer PCB.

Overview: How Are the Key Steps in 4-Layer PCBs Manufactured?

Below is the high-level process flow for 4-layer PCB manufacturing, which can serve as a roadmap for both newcomers and industry veterans:

- PCB Design & Stack-up Planning

- Material Preparation (Prepreg, Core, Copper Foil Selection)

- Inner Layer Imaging & Etching

- Layer Alignment & Lamination

- Drilling (CNC) & Hole Deburring

- Via Plating & Electroplating

- Outer Layer Patterning (Photoresist, Etching)

- Solder Mask Application & Curing

- Surface Finish Application (ENIG, OSP, HASL, etc.)

- Silkscreen Printing

- PCB Profiling (Routing, Cutting)

- Assembly, Cleaning, and Testing (AOI/ICT)

- Final Quality Control, Packaging, and Shipment

The following step-by-step guide dives deeply into each area, elaborating on best practices, terminology, and unique features of the 4-layer PCB fabrication process.

Step 1: Design Considerations

The journey of a four-layer PCB begins with the engineering team defining the circuit’s requirements, which are translated into detailed design files—including stackup definition, layer arrangement, and manufacturing outputs.

Key Elements of 4-Layer PCB Design:

- Layer Stack-up Selection: Common options like Signal | Ground | Power | Signal or Signal | Power | Ground | Signal. The choice here directly impacts electrical performance and manufacturability.

-

Material Selection:

- Core: Usually FR-4, though high-frequency, high-reliability designs might use Rogers, metal-core, or ceramic substrates.

- Prepreg: This glass fiber reinforced resin is critical for dielectric insulation and mechanical strength.

- Copper Weight: 1 oz is standard; 2 oz+ for power planes or special thermal jobs.

- Controlled Impedance Planning: For designs carrying high-speed or differential signals (USB, HDMI, Ethernet), controlled impedance requirements must be specified according to IPC-2141A guidelines.

-

Via Technology:

- Through-hole vias are standard for most four-layer PCBs.

- Blind/buried vias, back-drilling, and resin filling are custom options for high-density or high-frequency boards; they may require sequential lamination.

-

PCB Design Tools: Most 4-layer PCB projects start in professional CAD tools:

- Altium Designer

- KiCad

- Autodesk Eagle These platforms generate Gerber files and drill files—the standard digital blueprints sent to the manufacturer.

- Design for Manufacturing (DFM) Review: DFM checks are performed to ensure all elements are manufacturable—verifying trace/clearance, via aspect ratio, annular ring width, solder mask, silkscreen, and more. Early DFM feedback prevents costly redesigns or production delays.

Example Table: Typical 4-Layer PCB Stack-Up Options

|

Stack-Up Option

|

Layer 1

|

Layer 2

|

Layer 3

|

Layer 4

|

Best For

|

|

Standard (Most Common)

|

Signal

|

Ground

|

Power

|

Signal

|

Controlled impedance, EMI-sensitive

|

|

Alternative

|

Signal

|

Power

|

Ground

|

Signal

|

Return path management

|

|

High-Frequency

|

Signal

|

Ground

|

Ground

|

Signal

|

GHz+ circuits, superior isolation

|

|

Custom

|

Signal

|

Signal/Power

|

Ground

|

Signal

|

Mixed circuits, advanced EMC tailoring

|

Next Step

The next phase in the 4-layer PCB manufacturing process is Material Preparation—including core selection, prepreg management, and laminate cleaning.

Step 2: Material Preparation

Core Selection and Copper-Clad Laminate Handling

Every high-quality 4-layer PCB begins with the careful selection and preparation of its core materials. A typical four-layer PCB uses copper-clad laminates—insulating boards laminated on both sides with copper foil—as the internal “skeleton” of the PCB.

Material types include:

- FR-4: By far the most common core, offering a balanced cost-performance ratio for most applications.

- High TG FR-4: Used for boards requiring greater temperature resistance.

- Rogers, Teflon, and High-Frequency Laminates: Specified for RF and microwave PCBs where low loss and stable dielectric properties are critical.

- Metal-core (Aluminum, Copper): For power electronics or high thermal demands.

- Ceramic and CEM: Used in niche, high-performance applications.

Fact: The majority of multilayer PCBs in consumer, medical, and industrial electronics use standard FR-4 cores with a 1 oz copper weight as a starting point, optimizing for cost, manufacturability, and electrical reliability.

Cutting Laminates to Panel Size

PCB fabrication lines process boards in large panels, which are subdivided into individual PCBs after circuit patterning and assembly. Precision cutting of the copper-clad laminates and prepreg sheets ensures uniformity, maximizes material yield, and aligns with the panelization practices for the best cost efficiency.

Prepreg Usage in Layer Stack-Up

Prepreg (pre-impregnated composite fibers) is essentially a sheet of fiberglass cloth impregnated with partially cured epoxy resin. During lamination, prepregs are sandwiched between copper layers and cores, acting as both a dielectric (providing required insulation) and an adhesive (melting and bonding layers when heated).

Key Technical Points:

- Dielectric Thickness Compatibility: Prepreg and core thickness are tailored to reach target board thicknesses—e.g., 1.6 mm for standard 4-layer PCB stack-ups.

- Dielectric Constant (Dk): Modern applications (especially RF/high-speed digital) need well-characterized prepregs; Dk values directly influence the impedance of traces.

- Moisture Resistance: High-quality prepreg minimizes water absorption, which can otherwise affect electrical properties and reliability.

Pre-cleaning the Copper Surface

A vital yet often overlooked step in four-layer PCB fabrication is the pre-cleaning of copper surfaces on both core and foil materials:

- Brushing and Microetching: Materials are subjected to mechanical brushing and then dipped in a mild acid or chemical microetchant. This removes surface oxides, resins, and microparticles, exposing pristine copper for subsequent imaging.

- Drying: Any lingering moisture can weaken adhesion or cause delamination, so boards are carefully dried.

Material Traceability and Control

At this point, professional PCB manufacturers assign lot numbers to each panel and material batch. Traceability is essential for meeting quality standards (ISO9001, UL, ISO13485) and for problem tracing in the rare case issues emerge post-shipment.

Table: Typical Materials and Specs for a Standard 4-Layer PCB

|

Material

|

Usage

|

Typical Specs

|

|

FR-4 Core

|

Substrate

|

0.5 – 1.2 mm, 1 oz Cu

|

|

Prepreg

|

Dielectric

|

0.1 – 0.2 mm, Dk = 4.2 – 4.5

|

|

Copper Foil

|

Conductive

|

1 oz (35 µm) standard; 2 oz for power layers

|

|

Solder Mask

|

Protection

|

Green, 15–30 µm thick, LPI type

|

|

Silkscreen Ink

|

Markings

|

White, <0.02 mm raised

|

Proper material preparation forms the backbone of a reliable 4-layer PCB. Next, we move to a critical technical stage: Inner Layer Imaging and Etching.

Step 3: Inner Layer Imaging & Etching

The inner layer circuitry of a 4-layer PCB—typically the ground and power planes, or additional signal layers in specialized stack-ups—forms the electrical backbone for all signal routing and power distribution. This step is where your digital PCB design is physically realized with sub-millimeter accuracy on real copper.

1. Cleaning: Surface Preparation

Before imaging, the pre-cleaned copper cores (prepared in the previous step) undergo a final rinse and microetch process. This chemical microetch removes any last traces of oxidation, increases surface roughness on a microscopic level, and ensures optimal adhesion for the photoresist. Any contaminants left behind—even tiny ones—might cause under-etching, opens/shorts, or poor print resolution.

2. Photoresist Application

The cleaned copper-clad cores are then coated with photoresist—a light-sensitive polymer film that directly enables accurate circuit definition. Application is typically done via a dry-film lamination process, where the photoresist adheres tightly to the copper under heated rollers.

-

Types:

- Negative photoresist is the industry standard for multilayer boards; exposed areas cross-link and remain after development.

- Liquid photoresist can be used in some processes for finer control, though dry film prevails for most four-layer PCB fabrication.

3. Exposure (UV Imaging / Photo Tooling)

Next, the prepared core passes through an automated UV imaging machine, where a high-resolution laser or CAD-generated photomask aligns the circuit patterns over the copper-clad panel. Ultraviolet light shines through the clear portions of the mask:

- Where the mask is transparent: The photoresist is exposed and becomes polymerized (hardened).

- Where the mask is opaque: The photoresist remains soft and unexposed.

4. Development (Washing Unexposed Resist)

The panel is developed—immersed in a mild aqueous solution (developer). The unexposed, soft photoresist is washed away, exposing the copper underneath. Only the circuit pattern (now hard, exposed resist) remains, precisely matching the design provided in the Gerber files.

5. Etching (Copper Removal)

The PCB now undergoes inner layer etching—a controlled acid etch process, typically using an ammoniacal or ferric chloride solution:

- Etch removes the unwanted copper from areas not protected by the hardened photoresist.

- Circuit traces, pads, planes, and other designed copper features remain.

6. Resist Stripping

Once the desired copper patterns are revealed, the hardened photoresist protecting these areas is now stripped away using a separate chemical solution. Bare, shiny copper traces are left, accurately matching the inner layer artwork.

Quality Control: Automated Optical Inspection (AOI)

Each inner layer is rigorously inspected for defects using Automated Optical Inspection (AOI). High-resolution cameras scan for:

- Open circuits (broken traces)

- Under/over-etched features

- Shorts between traces or pads

- Alignment or registration errors

Why Inner Layer Etching is Critical for 4-Layer PCBs

- Signal Integrity: Clean, well-etched inner planes ensure consistent reference for high-speed nets, preventing noise and EMI.

- Power Distribution: Wide power planes minimize voltage drop and power dissipation.

- Plane Continuity: Maintaining broad, uninterrupted planes complies with IPC-2221/2222 and reduces impedance deviation.

"The accuracy of this stage sets the performance of your board. A single short or open in an internal power or ground layer results in total failure after lamination—impossible to repair. That’s why top PCB manufacturers prioritize imaging control and inline AOI." — kingfield

Step 4: Layer Alignment & Lamination

Proper alignment and lamination are essential in 4-layer PCB fabrication. This process physically bonds previously imaged copper layers (now holding the inner-circuit traces and planes) with prepreg sheets and outer copper foils—building the finished four-layer stackup.

A. Stack Preparation: Arranging the Layup

The fabrication line now assembles the internal structure, using:

- Inner Layer Cores: Finished (etched, cleaned) inner cores—typically ground and power plane layers.

- Prepreg: Carefully measured dielectric (insulating) layers placed between copper cores and the outer copper foils.

- Outer Copper Foils: Sheets that will become the top and bottom routing layers after circuit imaging.

B. Pinning and Registration (Layer Alignment)

Alignment is not just a mechanical requirement—it’s crucial for:

- Maintaining pad-to-via registration, so that drilled holes later on won’t miss, clip, or short to adjacent features.

- Keeping reference planes directly below critical signal routes to maintain signal integrity and controlled impedance.

How alignment is achieved:

- Pinning: Precision steel pins and registration holes are punched through the sandwich stack to hold all panels in absolute alignment during build-up.

- Optical Registration: Advanced PCB shops use automated optical systems to verify and enhance layer-to-layer registration, often achieving ±25 μm (microns) tolerance.

C. Lamination: Heat and Pressure Fusion

The stacked and pinned layup is then loaded into a hot press laminator:

- Vacuum Stage: Removes trapped air and volatile residues, preventing delamination or voids.

- Heat and Pressure: Prepreg softens and flows under temperatures of 170–200°C (338–392°F) and pressures of 1.5–2 MPa.

- Cure: The softened resin in the prepreg fills microvoids and bonds layers together, then hardens (polymerizes) as it cools.

The outcome is a single rigid, bonded panel—with four distinct, electrically isolated copper layers perfectly laminated and set for further processing.

Quality Control: Post-Lamination Inspection and Testing

After lamination, the panel is cooled and cleaned. Essential QC checks include:

- Thickness and Warp Measurements: Ensures the board is flat and meets specified tolerances (typically ±0.1mm).

-

Destructive Cross-Section Analysis: Sample boards are sliced and analyzed under a microscope to verify:

- Insulation between layers (no delamination, voids, or resin starvation).

- Layer registration (layer-to-layer accuracy).

- Bonding quality at the prepreg-core interfaces.

- Visual Inspection: Checks for delamination, deformation, and surface contamination.

IPC Standards and Best Practices

- IPC-6012: Specifies performance and inspection requirements for rigid PCBs, including multilayer alignment and lamination quality.

- IPC-2221/2222: Recommends continuous planes, minimal slots, and strict registration tolerances for robust performance.

- Materials: Use industry-grade prepreg, core, and copper—preferably with traceable batch numbers for quality control and regulatory reporting.

Summary Table: Benefits of Precise Lamination in 4-Layer PCBs

|

Benefit

|

Details

|

|

Superior Signal Integrity

|

Maintains proper ground/signal plane relationships

|

|

Reliable Interconnects

|

Guarantees drilled vias will hit all necessary pads/planes

|

|

Mechanical Durability

|

Withstands thermal/mechanical stresses in assembly/use

|

|

Reduced EMI

|

Minimizes layer offset, preventing EMI “hot spots”

|

|

Manufacturing Yield

|

Fewer defects, lower scrap, better cost efficiency

|

Step 5: Drilling and Plating

The drilling and plating stage of four-layer PCB fabrication is where the board’s physical and electrical connectivity truly comes to life. Accurate via formation and robust copper electroplating are essential for reliable signal and power transmission in multilayer stackups.

A. CNC Drilling of Vias and Component Holes

Modern 4-layer PCB manufacturing employs computer-controlled (CNC) drilling machines to create hundreds or even thousands of holes per panel—delivering accuracy, speed, and repeatability that are critical for advanced applications.

Types of Holes in 4-Layer PCBs:

- Through-hole vias: Extend all the way from the top layer to the bottom, connecting every copper plane and layer. These form the backbone for both signal and ground interconnects.

- Component holes: Pads for through-hole (THT) components, connectors, and pins.

-

Optional:

- Blind vias: Connect an exterior layer to one (but not both) internal layers; less common in 4-layer boards due to cost.

- Buried vias: Connect only internal layers; used in high-density projects or rigid-flex hybrid PCBs.

Drilling process highlights:

- Panel Stacking: Multiple panels may be drilled simultaneously to optimize throughput, each supported by a phenolic entry/exit board to prevent burring or drill wander.

- Bit Selection: Carbide or diamond-coated bits ranging from 0.2 mm (8 mils) upwards. Bit wear is closely monitored and replaced at strict intervals for high consistency.

- Hole Position Tolerance: Typically ±50 µm, essential for via-pad alignment in high-density designs.

B. Deburring and Desmearing

Once drilling is complete, mechanical processing leaves rough edges (burrs) and epoxy “smears” on the via wall, especially where glass fibers and resin are exposed. Left untreated, these can block plating or cause reliability problems.

- Deburring: Mechanical brushes remove sharp edges and foil debris.

- Desmearing: Panels are chemically treated (using potassium permanganate, plasma, or permanganate-free methods) to strip away resin residues and fully expose the glass fiber and copper for subsequent metal bonding.

C. Via Formation and Copper Electroplating

Arguably the most critical step—via plating—creates the all-important electrical channels between layers of the 4-layer PCB.

The process includes:

- Hole Wall Cleaning: Panels undergo pre-treatment (acid cleaning, micro-etching) to ensure pristine surfaces.

- Electroless Copper Deposition: A thin layer (~0.3–0.5 µm) of copper is chemically deposited onto the hole walls, “seeding” the via for further electroplating.

- Electroplating: PCB panels are placed into copper baths. Direct current (DC) is applied; copper ions plate onto all exposed metal surfaces—including via walls and through-holes—building a uniform, conductive copper tube throughout each hole.

- Standard Copper Thickness: Finished via walls are typically plated to a minimum of 20–25 µm (0.8–1 mil), in line with IPC-6012 Class 2/3 or customer specs.

- Uniformity Checks: Sophisticated thickness monitoring and cross-sectioning are used to guarantee no thin spots or voids, which could cause open circuits or intermittent field failures.

Quality Control:

- Cross-section analysis: Sampled holes are cut and measured for wall thickness, adhesion, and uniformity.

- Continuity tests: Electrical checks ensure every via establishes a solid connection from pad to pad, layer to layer.

D. Why Drilling and Plating Matter for 4-Layer PCBs

- High Reliability: Uniform, defect-free via plating prevents open/short faults and catastrophic field failures. - Signal Integrity: Proper via formation supports fast signal transitions, low resistance ground returns, and reliable power delivery. - Advanced Design Support: Enables finer feature sizes, dense packaging, and compatibility with technologies like HDI or rigid-flex PCB hybrids.

Table: Drilling and Plating Parameters for Standard 4-Layer PCBs

|

Parameter

|

Typical Value

|

Note

|

|

Min. Finished Hole Size

|

0.25–0.30 mm (10–12 mil)

|

Smaller for HDI/advanced processes

|

|

Hole Wall Copper Thickness

|

≥ 20 µm (0.8 mil, IPC-6012)

|

Up to 25–30 µm in high-reliability specs

|

|

Via Aspect Ratio

|

Up to 8:1 (board thickness : hole)

|

Higher ratios require careful DFM

|

|

Plating Uniformity

|

±10% across panel

|

Monitored by test coupons/X-ray

|

Step 6: Outer Layer Patterning (Circuit Generation on Layers 1 & 4)

The outer layers of your 4-layer PCB—Layers 1 (top) and 4 (bottom)—contain the pads, tracks, and copper features that will directly interact with components or connectors during assembly. This stage is similar in spirit to inner layer processing, but the stakes are higher: these layers undergo significant soldering, cleaning, and wear and must meet the most stringent cosmetic and dimensional standards.

A. Outer Layer Photoresist Application

As with inner layers, outer copper foils are first cleaned and microetched to provide a pristine surface. A layer of photoresist (typically dry film) is then laminated across each surface using heated rollers to ensure adhesion.

- Fact: High-quality PCB manufacturers carefully control both film thickness and lamination pressure, ensuring consistent image development and minimization of edge distortions.

B. Imaging (Photo Tooling/UV Laser Direct Imaging)

- Photo Tooling: For most mass runs, photomasks containing the copper track and pad patterns for both top and bottom layers are optically aligned to the drilled holes.

- Laser Direct Imaging (LDI): In high-precision or quick-turn projects, a computer-controlled laser “writes” the Gerber-defined traces and pads directly onto the panel with micron-level accuracy.

- Ultraviolet (UV) light cures the exposed photoresist, locking the precise outer circuitry into place.

C. Development and Etching

- Development: Unexposed photoresist is washed away with a mild alkaline developer, uncovering copper to be etched away.

- Acid Etching: Exposed copper is removed by high-speed conveyor etchers, leaving only the traces, pads, and exposed circuits protected by the hardened photoresist.

- Stripping: The remaining photoresist is stripped, revealing the fresh, shiny external copper structures that form the solderable surfaces and current-carrying tracks for your board.

Table: Key Dimensions for 4-Layer PCB Outer Patterning

|

Feature

|

Standard Value

|

Note

|

|

Trace Width

|

0.15–0.25 mm (6–10 mil)

|

For most digital, power & mixed-signal designs

|

|

Space

|

0.15–0.20 mm (6–8 mil)

|

Controlled for IPC Class 2/3

|

|

Annular Ring

|

≥0.1 mm (4 mil)

|

DFM-dependent, ensures reliable solder joints

|

|

Pad-to-Pad Tolerance

|

±0.05 mm (2 mil)

|

For high-density LSI/SMT

|

D. Inspection and Quality Checks

The newly etched panels are inspected visually and via AOI (Automated Optical Inspection) for:

- Over/under-etched traces and pads

- Bridges or shorts

- Opens or missing features

- Registration/alignment with pre-drilled vias

Why Outer Layer Patterning Matters for 4-Layer PCBs

- Assembly Reliability: Solderability, pad size, and track robustness are all defined here.

- Signal Integrity: High-speed signals, differential pairs, and controlled impedance nets terminate on these layers, making precision trace definition vital.

- Power Handling: Enough copper is left for all routing and heat dissipation needs.

Step 7: Solder Mask, Surface Finish, and Silkscreen

After completing the copper patterning for your 4-layer PCB’s outer layers, it’s time to impart durability, solderability, and clarity for both assembly and field maintenance. This multi-part step distinguishes professional multilayer PCB fabrication by protecting the circuit, guaranteeing reliable soldering, and ensuring simple visual identification.

A. Solder Mask Application

The solder mask is a protective polymer coating—typically green, though blue, red, black, and white are also popular—applied to both the top and bottom surfaces of the PCB:

-

Purpose:

- Prevents solder bridges between closely spaced pads and tracks.

- Protects external circuitry from oxidation, chemical attack, and mechanical abrasion.

- Improves electrical insulation between traces, further enhancing signal integrity and EMI reduction.

Application Process:

- Coating: The panel is coated with liquid photoimageable (LPI) solder mask, covering all but the copper pads that will later be soldered.

- Imaging and Exposure: UV light is used with an artwork mask to define openings (for pads, test points, vias).

- Developing: Unexposed solder mask is washed away, while the exposed hardens, protecting circuits.

- Curing: Panels are baked or UV-cured to fully harden the mask.

B. Surface Finish Options

To ensure all exposed pads withstand storage, resist oxidation, and offer flawless solderability during assembly, a surface finish is applied. There are several finishes to suit applications, cost, and assembly requirements:

|

Surface Finish

|

Acronym

|

Key Advantages

|

Typical Use Cases

|

|

Electroless Nickel Immersion Gold

|

ENIG

|

Flat, oxidation-proof, suitable for fine-pitch/BGA; excellent solderability, RoHS-compliant

|

High-reliability, HDI, consumer, RF

|

|

Organic Solderability Preservative

|

OSP

|

Clean, lead-free, economical; protects bare copper and easy for reflow soldering

|

Mass-market, simple SMT

|

|

Immersion Tin

|

—

|

Planar, good for press-fit or high-speed connectors

|

Controlled impedance, press-fit boards

|

|

Immersion Silver

|

—

|

Excellent for high-frequency/signal integrity

|

RF, high-speed digital

|

|

Hot Air Solder Leveling / Lead-Free HASL

|

HASL

|

Widely used, cost-effective, robust; molten solder coating

|

General electronics, THT/SMT mixed

|

- ENIG is industry standard for most 4-layer prototype and production boards, especially where surface flatness and high density (BGA, LGA, QFN) matter.

- OSP is best for lead-free consumer electronics needing cost efficiency and good solder joint quality.

Differences between ENIG and HASL:

- ENIG offers a smoother and more planar surface, required for ultra-fine-pitch and BGAs.

- HASL creates uneven “domes” that may not suit modern high-density PCB assembly.

- ENIG is costlier but offers better long-term storage and wire-bonding compatibility.

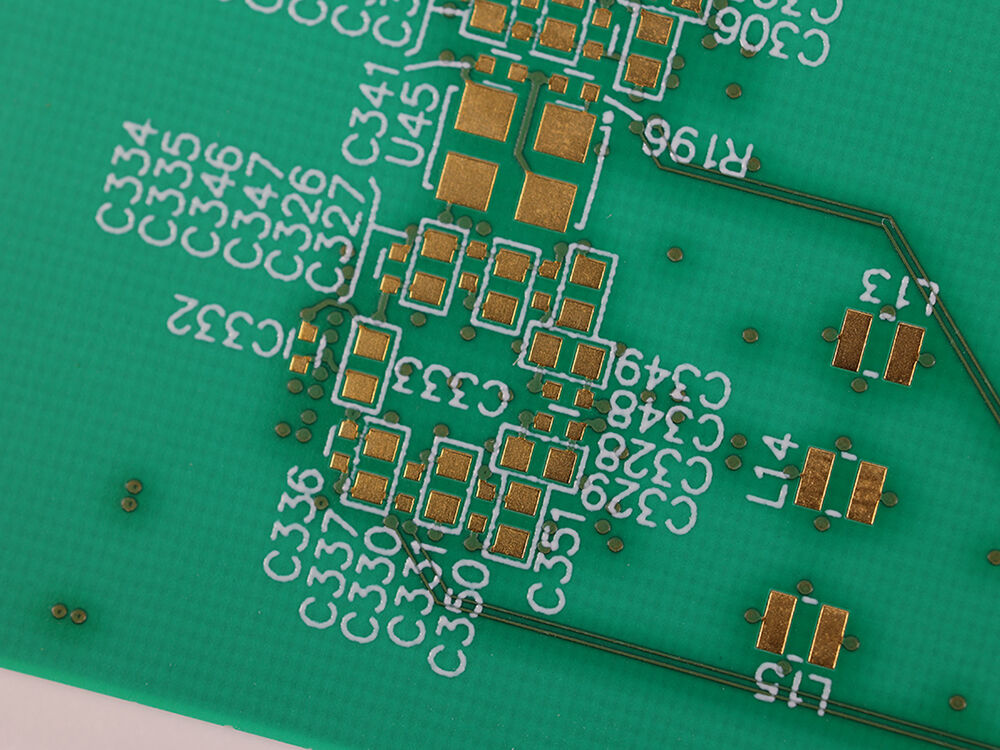

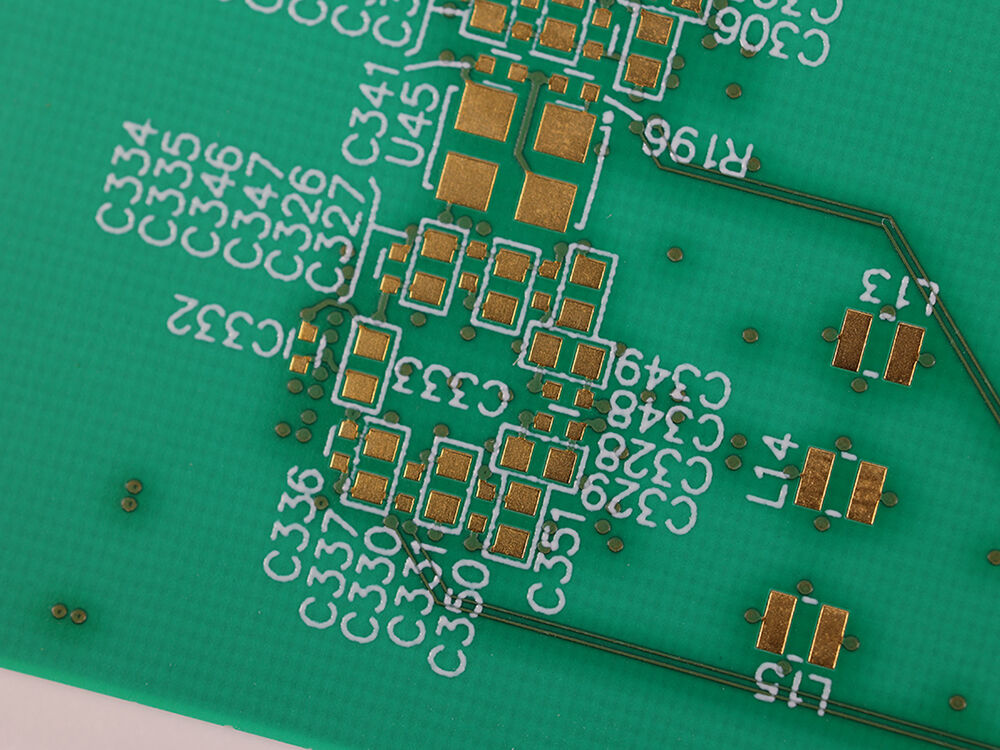

C. Silkscreen Printing

With solder mask and surface finish in place, the final layer is the silkscreen—used to mark:

- Component outlines and labels (R1, C4, U2)

- Polarity markers

- Reference designators

- Pin 1 indicators, logos, revision codes, and barcodes

Quality Control: Final AOI and Visual Checks

- Automated Optical Inspection (AOI): Ensures mask opening size/placement, absence of stray solder mask, and correct pad exposure.

- Visual Inspection: Confirms silkscreen clarity, absence of missing ink, solder mask over main features, and verifies surface finish integrity.

Why This Stage Matters for 4-Layer PCBs

- Solderability: Only the exposed pads/touch points are accessible for soldering; masking the rest prevents accidental bridges—critical in dense designs.

- Corrosion & Contamination Resistance: Board lifespan and reliability are dramatically improved by shielding copper surfaces from air, moisture, and fingerprints.

- Error Reduction: Strong, accurate markings reduce assembly mistakes, rework, or field service time.

Step 8: PCB Profiling, Assembly, and Cleaning

With all circuit layers set, vias plated, and solder mask and surface finish applied, te focus now shifts to shaping, populating, and cleaning the 4-layer PCB. This phase takes your multilayer panel from a precision-fabricated, but undifferentiated, block to a form-factor-specific, fully assembled functional device.

A. PCB Profiling (Cutting and Routing)

At this stage, multiple PCB images reside on a larger production panel. Profiling means singulating each four-layer printed circuit board to its required outline, including any cutouts, slots, or V-grooves.

Key Methods:

- CNC Routing: High-speed carbide bits trace the board's outer edge precisely, meeting tolerance specifications as tight as ±0.1 mm.

- V-Scoring: Shallow grooves allow for easy board depanelization by snapping along score lines.

- Punching: Used for high-volume, standard-shape boards to optimize throughput.

B. PCB Assembly (SMT & THT Component Placement)

Most 4-layer PCB boards today use mixed-technology assembly, leveraging both Surface Mount Technology (SMT) for high-density, automated population, and Through-Hole Technology (THT) for high-strength connectors, power parts, or legacy components.

1. SMT Assembly

- Stencil Printing: Solder paste is screen-printed onto pads using laser-cut stencils for precision volume.

- Pick-and-Place: Automated machines place up to tens of thousands of components per hour with micron-level accuracy—even for 0201 passives, QFNs, BGAs, or LSI devices.

- Reflow Soldering: Loaded PCBs travel through a carefully profiled forced-air oven, sequentially melting and cooling the solder. This creates robust solder joints for all SMT devices.

2. THT Assembly

- Manual or Automated Insertion: Components with long leads, such as connectors or large electrolytic capacitors, are inserted through plated holes.

- Wave Soldering: Boards pass over a molten solder wave to simultaneously solder all inserted leads—a time-tested approach for robust mechanical strength.

SMT vs. THT:

- SMT enables high-density, lightweight, and compact assemblies. Best for modern multilayer PCBs.

- THT is still preferred for connectors and high-power parts requiring extra anchoring.

C. Cleaning (Isopropyl Alcohol and Dedicated PCB Washes)

After soldering, residues like flux, solder balls, and dust can compromise reliability, especially across the closely spaced tracks and vias of four-layer printed circuit boards.

Process Steps:

- Isopropyl Alcohol (IPA) Cleaning: Common in prototyping and low-volume runs, manually removes ionic residues and visible flux.

- In-Line PCB Washers: Industrial washers use deionized water, saponifiers, or specialized solvents to clean multiple boards at once—critical in medical, military, and automotive sectors.

Why Cleaning Matters:

- Prevents corrosion and dendritic growth between circuit features.

- Reduces risk of electrical leakage paths, especially for high-impedance or high-voltage circuits.

Table: Assembly and Cleaning Process Overview

|

Stage

|

Technique

|

Advantages

|

Typical Applications

|

|

Profiling

|

CNC Routing, V-Scoring

|

Precision, stress-free edges

|

All board types

|

|

SMT Assembly

|

Stencil/Reflow

|

High density, speed, accuracy

|

Mass-market, high-density

|

|

THT Assembly

|

Wave Soldering

|

Robust joints, handles bulky parts

|

Power, connectors

|

|

Cleaning

|

IPA or In-line Washer

|

Removes residues, ensures reliability

|

All, especially critical

|

Step 9: Final Testing, Quality Control (QC), and Packaging

A 4-layer PCB is only as good as the rigor of its testing and quality control. Even if it looks perfect to the naked eye, invisible defects—shorts, opens, misalignments, or inadequate plating—can cause erratic behavior, early failures, or safety risks. That’s why top-tier PCB manufacturers employ a comprehensive suite of electrical, visual, and documentation-based inspections backed by internationally recognized IPC standards.

A. Automated Optical Inspection (AOI)

Automated Optical Inspection (AOI) is performed multiple times throughout multilayer PCB fabrication, with the most critical pass after final assembly and soldering.

- How it works: High-resolution cameras scan both sides of each PCB, comparing every trace, pad, and solder joint to the digital Gerber files.

-

What AOI detects:

- Opens (broken traces)

- Shorts (solder bridges)

- Missing or displaced components

- Solder joints with insufficient or excess solder

- Tombstoning or component misalignment

B. In-Circuit Testing (ICT)

In-Circuit Test (ICT) is the gold standard for verifying assembled 4-layer PCB functionality:

- Contact Probes: Bed-of-nails or flying probe testers make contact with dedicated test points or component pins.

- Test Scripts: Drive signals through the circuit, measuring responses at key nodes.

-

Parameters Checked:

- Continuity between all signal and power points

- Resistance/capacitance of key nets

- Integrity of vias and plated-through holes

- Presence/absence and orientation of main components

ICT allows:

- Immediate, board-level diagnosis (pinpointing faulty solder joints, opens, or mis-placed parts)

- Batch-level statistics for process monitoring

C. Electrical Testing

Every finished four-layer PCB undergoes a full “shorts and opens” electrical continuity test. In this step:

- Electrical Test (ET): High-voltage is applied across all traces and interconnections.

- Objective: Detect any hidden “opens” (disconnects) or “shorts” (unintentional bridges), regardless of visual appearance.

For impedance-controlled designs:

- Impedance Coupons: Test traces made of the same stackup and process as production nets allow measurement and validation of characteristic impedance (e.g., 50 Ω single-ended, 90 Ω differential).

D. Documentation and Traceability

- Gerber, Drill, and Test Files: The manufacturer compiles and archives all critical data, ensuring traceability from material batch to finished board.

- Assembly Drawings and QC Certificates: Accompany high-reliability shipments for compliance with ISO9001/ISO13485, medical, or automotive standards.

- Barcoding: Serial numbers and barcodes are printed on each board or panel for tracking, troubleshooting, and “digital twin” referencing.

E. Final Visual Inspection and Packaging

Trained inspectors perform a last check using magnification and high-intensity lighting to examine critical features:

- Pad and via cleanliness (no solder balls or residues)

- Markings, labeling clarity, orientation, and revision code accuracy

- Edge and profiling quality (no delamination, chipping, or damage)

Packaging:

- Vacuum-sealed anti-static bags shield against ESD and moisture ingress

- Bubble wrap, foam, or custom trays prevent physical shock during shipment

- Each lot packed per client instructions, including desiccant packs or humidity indicators for high-reliability markets

Table: Testing and QC Standards for 4-Layer PCBs

|

Test/Inspection

|

Standard/Reference

|

What It Ensures

|

|

AOI

|

IPC-610, ISO9001

|

Visible defect-free build

|

|

Electrical Test (ET)

|

IPC-9252

|

No shorts/opens

|

|

ICT/Flying Probe

|

Custom/IPC-2222

|

Functionality, pin-specific test

|

|

Impedance Check

|

IPC-2141A, coupons

|

Transmission line compliance

|

|

Visual Inspection

|

IPC-A-610, ISO13485

|

Cosmetic and mechanical quality

|

How to Create a 4-Layer Stackup in Altium Designer

Controlling your 4-layer PCB stackup is crucial for achieving the right balance between electrical performance, manufacturability, and cost. Modern PCB design tools like Altium Designer provide intuitive, powerful interfaces for specifying—and later exporting—every detail manufacturers need for high-quality, reliable multilayer PCB fabrication.

Step-by-Step: Defining Your 4-Layer PCB Stackup

1. Start Your Project in Altium

- Open Altium Designer and create a new PCB project.

- Import or draw your schematics, ensuring all components, nets, and constraints are defined.

2. Access the Layer Stack Manager

- Go to Design → Layer Stack Manager.

- The Layer Stack Manager lets you configure all conductive and dielectric layers, thicknesses, and materials.

3. Add Four Copper Layers

- By default, you'll see Top Layer and Bottom Layer.

- Add two inner layers (typically named MidLayer1 and MidLayer2) for your four-layer build.

4. Define the Layer Functions

Assign common purposes to each layer as follows:

|

Layer

|

Typical Function

|

Stack Example

|

|

Top

|

Signal + Components

|

L1 (Signal)

|

|

MidLayer1

|

Ground Plane

|

L2 (Ground)

|

|

MidLayer2

|

Power Plane (VCC etc)

|

L3 (Power)

|

|

Bottom

|

Signal / Components

|

L4 (Signal)

|

5. Configure Dielectric/Prepreg and Core Thicknesses

- Click between layers to set the dielectric thickness (prepreg, core) using manufacturer-specified values.

- Typical total thickness for a 4-layer PCB: 1.6mm (but can be thinner/thicker as needed).

- Input dielectric constant (Dk) and loss tangent values, especially for controlled impedance designs.

6. Assign Copper Weight

- Specify copper thickness for each layer: usually 1 oz/ft² (~35 μm) is standard for signal layers; 2 oz or more for high-current power.

- These values affect trace width calculations and mechanical durability.

7. Enable Impedance Calculations

- Use the built-in Impedance Calculator (or link to your manufacturer’s tool) to calculate single-ended and differential pair impedances based on your material, thickness, and width/space entries.

- Typical targets: 50Ω single-ended, 90–100Ω differential.

- Tweak dielectric thickness, trace width, and copper weight as needed to hit these targets.

8. Generate the Stackup Drawing

- Export a stackup drawing (DXF, PDF, etc.) for your fab notes. This helps prevent communication errors and speeds up DFM review.

9. Prepare and Export Gerber and Drill Files

- Set up final stackup confirmation for your board outline, layer order, and annotations.

- Export all Gerber files, Drill files, and stackup diagrams with precise naming (including layer names matching your stackup manager).

Case Study: Optimizing a 4-Layer PCB Stackup for High-Speed Signals

Scenario: A telecommunications startup designed a new router using Altium Designer. Their primary challenge was reducing signal crosstalk and keeping USB/Ethernet signals within tight impedance tolerances.

Solution:

- Used Altium’s Layer Stack Manager to create [Signal | Ground | Power | Signal] with a 0.2mm prepreg between ext. and internal planes.

- Set copper weights to 1 oz for all layers.

- Used Altium’s impedance calculator and coordinated materials with their manufacturer, quickly iterating until measurements matched 50Ω and 90Ω targets within ±5%.

- Result: The first batch passed EMC and high-speed integrity testing—accelerating certification and saving development time.

Why Stackup Design in Altium Matters for 4-Layer PCBs

- Prevents Costly Redesigns: Early stackup planning with manufacturer inputs prevents delays and ensures smooth transitions from prototype to production.

- Facilitates DFM Checks: Well-documented stackups help catch DRC/DFM mismatches before boards are fabricated.

- Supports Advanced Features: Accurate stackup control is necessary for technologies such as via-in-pad, blind/buried vias, and controlled impedance routing.

Best Practices for 4-Layer PCB Stackup & Layout

A robust 4-layer PCB stackup is only half the equation—true performance, reliability, and yield come from applying disciplined best practices in layout and design. When you optimize stackup, routing, decoupling, and thermal paths with careful intent, your four-layer PCB manufacturing process yields boards that excel in signal integrity, EMC, manufacturability, and lifecycle durability.

1. Signal and Power Integrity Considerations

Controlled signal return paths and clean power distribution are foundational in multilayer PCB design. Here’s how to get it right:

- Place signals on the outer layers (L1, L4) and dedicate inner layers (L2, L3) as solid ground (GND) and power (VCC) planes.

- Never break up internal planes with large cutouts or slots—instead, keep planes continuous. As per IPC-2221/2222, discontinuities can cause controlled impedance to deviate by 5–15%, which may lead to signal degradation or intermittent failures.

- Short signal return paths: High-speed and noise-critical signals should always “see” a solid reference plane directly below. This reduces loop area and suppresses radiated EMI.

Table: Typical 4-Layer PCB Stackup Usage

|

Option

|

L1

|

L2

|

L3

|

L4

|

Best For

|

|

Standard

|

Signal

|

Ground

|

Power

|

Signal

|

General, controlled impedance, EMC

|

|

Alternate

|

Signal

|

Power

|

Ground

|

Signal

|

Improved power – ground coupling

|

|

Custom

|

Signal/Power

|

Ground

|

Ground

|

Signal/Power

|

RF, GHz, ultra-quiet digital

|

2. Component Placement and Decoupling

- Group high-speed ICs near connectors or sources/loads to minimize trace lengths and via count.

- Place decoupling capacitors as close as possible (preferably directly over vias to the power plane) to ensure stable local VCC.

- Critical nets first: Route high-frequency, clock, and sensitive analog nets before less-critical signals.

Best Practice: Use the "fanout" technique: move signals out from BGAs and fine-pitch packages using short traces and direct vias—minimizes crosstalk and stub effects.

3. Routing for Controlled Impedance

- Trace width and spacing: Calculate and set in design rules for 50Ω single-ended and 90–100Ω differential pairs using the correct stackup settings (dielectric thickness, Dk, copper weight).

- Minimize stub length: Avoid unnecessary transitions between layers, and use back-drilling for critical signals to remove unused via portions.

- Layer transitions: Place differential pairs on the same layer whenever possible, and avoid unnecessary crossings.

4. Via Strategy and Stitching

- Use via stitching on solid ground planes—surrounding high-speed signals, clock nets, and RF zones with closely spaced ground vias (usually every 1–2 cm).

- Optimize via size and aspect ratio: IPC-6012 recommends aspect ratios (board thickness to finished hole size) generally not to exceed 8:1 for high reliability.

- Back-drilled vias: For ultra-high-speed, use back-drilling to remove via stubs and further reduce signal reflections.

5. Thermal Management and Copper Balance

- Thermal vias: Put arrays of thermal vias under hot-running ICs/LDOs to connect heat to the ground plane and spread it.

- Copper pour: Use balanced copper distribution on both outer layers to prevent warping/twisting in larger or high-power boards.

- Controlled copper area: Avoid large unconnected copper “islands” that can create voltage coupling or EMI.

6. EMI Shielding & Crosstalk Prevention

- Route orthogonal signal directions: Route signals on L1 and L4 at right angles (e.g., L1 running east-west, L4 running north-south)—this reduces capacitive coupling and crosstalk through the planes.

- Keep high-speed signals away from board edges, and avoid running parallel with the edge, which can radiate more EMI.

7. Verification with Simulation and Manufacturer Feedback

- Perform pre-layout and post-layout signal integrity simulations for critical nets or interfaces.

- Review stackup and routing constraints with your chosen 4-layer PCB manufacturer—using their experience to head off manufacturability and reliability risks early in the process.

Quote from Ross Feng: “At Viasion, we’ve seen that disciplined best practices at the design level—solid planes, disciplined via usage, thoughtful trace/plane relationship—yield more reliable four-layer PCBs, lower EMI, and a shorter debug cycle for our customers.”

Summary Table: Do’s and Don’ts for 4-Layer PCB Layout

|

Do’s

|

Don’ts

|

|

Use continuous ground and power planes

|

Split inner planes; avoid slots

|

|

Place decoupling caps close to power vias

|

Route high-speed signals without reference plane

|

|

Calculate and enforce controlled impedance

|

Ignore fab stackup values

|

|

Optimize via aspect ratio and spacing

|

Overuse stubs/cross planes needlessly

|

|

Use copper balance to mitigate warpage

|

Leave large unconnected copper zones

|

Factors Affecting 4-Layer PCB Cost

Cost control is a central concern for every engineering manager, designer, and procurement specialist working with 4-layer PCBs. Understanding the variables that affect multilayer fabrication pricing enables smart, cost-effective decisions—without sacrificing signal quality, reliability, or product features.

1. Material Selection

-

Core and Prepreg Types:

- Standard FR-4: Most cost-effective, suitable for the majority of commercial and industrial applications.

- High-TG, Low-Loss, or RF Materials: Rogers, Teflon, and other specialty substrates are essential for high-frequency, high-reliability, or thermal-critical designs, but can add 2–4x to substrate costs.

-

Copper Weight:

- 1 oz (35µm) is the norm; upgrading to 2 oz or more for power planes or thermal management increases both materials and processing expense.

-

Surface Finish:

- ENIG (Electroless Nickel Immersion Gold): Higher cost, but necessary for fine-pitch, high-reliability, or wire bonding.

- OSP, HASL, Immersion Silver/Tin: More affordable, but may have tradeoffs in shelf life or flatness.

2. Board Thickness and Dimensions

- Standard thickness (1.6mm) is most economical, optimizing panel utilization and minimizing special process steps.

- Custom thicknesses, very thin (<1.0mm) or thick (>2.5mm) boards require special handling and may limit manufacturer options.

Table: Sample Board Thicknesses and Typical Uses

|

Thickness

|

Applications

|

Cost Impact

|

|

1.0 mm

|

Wearables, high-density portables

|

Neutral

|

|

1.6 mm

|

General-purpose, industry standard

|

Lowest

|

|

2.0+ mm

|

Power, connectors, mechanical stress

|

10-20% higher

|

3. Design Complexity

- Trace/spacing widths: <=4 mils increase cost due to higher rejection and slower yield.

- Minimum Via Size: Microvias, blind/buried, or via-in-pad add significantly to fabrication effort.

- Layer Count: Four-layer PCB is the “core” of mass-market multilayer; adding more layers (6, 8, 12, etc.) or nonstandard stackups proportionally increases the price.

4. Panelization and Utilization

- Large panels (multiple boards per panel) maximize throughput and material efficiency, keeping per-board cost low.

- Odd-shaped or large boards (requiring more waste or dedicated tooling) reduce panel density and cost efficiency.

5. Special Processing Requirements

- Controlled Impedance: Requires tighter control of trace width, spacing, and dielectric thickness—may need additional QA/testing steps.

- Gold Fingers, Slotting, Scoring, Edge Plating: Any nonstandard mechanical or finishing process adds to NRE (non-recurring engineering) and per-part cost.

- Sequential Lamination, Back-Drilling: Essential for blind/buried vias or high-speed designs, but adds steps, time, and complexity.

6. Volume and Lead Time

- Prototyping and small runs: Typically $10–$50/board, depending on features, since setup cost is amortized over fewer units.

- Mid-to-High volumes: Unit cost drops sharply—especially if your design is panel-optimized and uses mainstream specs.

- Quick-turn: Expedited fab/delivery (as fast as 24–48 hours) adds premium charges—plan ahead where possible.

7. Certifications and Quality Assurance

- UL, ISO9001, ISO13485, Environmental Compliance: Certified facilities and documentation cost more but are necessary for automotive, medical, and exacting commercial projects.

Cost Comparison Table: 4-Layer PCB Example Quotes

|

Feature

|

Basic FR-4, OSP

|

ENIG, High-TG, Impedance Control

|

|

1.6mm, 1 oz, 0.3mm min hole, std. finish

|

$15–$25 per board (qty 10)

|

$30–$60 per board (qty 10)

|

|

2.0mm, 2 oz, ENIG, 4 mil/4 mil, controlled impedance

|

$30–$45 per board (qty 10)

|

$45–$70 per board (qty 10)

|

|

Rigid-flex hybrid (same dimensions)

|

$60–$100+

|

Not typical

|

How to Get the Best Value from 4-Layer PCB Manufacturing

- Supply complete stackup and mechanical drawings up front

- Respond quickly to DFM feedback, revising for manufacturability

- Choose proven, certified Shenzhen or global suppliers

- Optimize array/panel design for volume production

- Work with suppliers like Viasion Technology, which offer in-house cost engineering and free DFM file checks

Choosing the Right 4-Layer PCB Manufacturer

The decision of where you have your 4-layer PCB manufactured can have a major impact on your project’s cost, electrical performance, production lead time, and long-term device reliability. While four-layer PCB fabrication is a mature process, only a subset of suppliers consistently deliver the accuracy, repeatability, and documentation that markets like automotive, industrial, medical, and consumer electronics demand.

1. Certifications and Compliance

Look for manufacturers certified to:

- UL (Underwriters Laboratories): Ensures flammability compliance and safe operating characteristics.

- ISO 9001 (Quality Systems): Signals solid process control and documentation from design through shipment.

- ISO 13485 (Medical): Mandatory for medical-grade PCB assemblies and devices.

- Environmental (RoHS, REACH): Indicates control over hazardous substances and global market compliance.

2. Technical Capabilities and Experience

A top-tier 4-layer PCB manufacturer should offer:

- Precision Stackup Control: Able to deliver tight tolerances on dielectric thickness, copper weights, and via geometries.

- Advanced Via Technologies: Through-hole, blind/buried vias, via-in-pad, and back-drilling for high-speed, high-density, and custom stackups.

- Controlled Impedance Fabrication: Onsite impedance test coupons, matched test benches, and expertise with single-ended/differential designs.

- Flexible Panelization: Efficient use of materials for various board sizes and shapes, with internal consultation to help lower your cost per board.

- End-to-End Services: Including quick-turn prototyping, full-scale production, and value-added options like functional assembly, conformal coating, and box build.

3. Communication and Support

Responsiveness and clear technical support set good PCB suppliers apart:

- Early DFM and Stackup Reviews: Proactively flagging DFM or impedance issues before fabrication starts.

- English-language Engineering Teams: For international customers, ensures nothing gets lost in translation.

- Online Quoting and Tracking: Real-time quote tools and order status tracking increase transparency and project planning accuracy.

4. Value-Added Services

- PCB Design and Layout Assistance: Some suppliers can review or co-design layouts for optimal manufacturability or signal integrity.

- Component Sourcing and Assembly: Turnkey assembly drastically compresses lead times and logistics for prototypes or pilot runs.

- Prototyping to Mass Production: Select a shop that scales with your volumes, offering consistent process control from the first board to the millionth unit.

5. Location and Logistics

- Shenzhen/Guangdong Region: Global hub for high-quality, fast-turn multilayer PCB manufacturing, with mature supply chains, abundant material stocks, and robust export infrastructure.

- Western Options: North America or Europe offers UL/ISO-certified fabrication with higher labor costs—best for low-to-mid volumes requiring short delivery times or special regulatory compliance.

How to Vet Your 4-Layer PCB Manufacturer

|

Vetting Step

|

What to Check/Ask

|

|

Certifications

|

Ask for/view UL, ISO9001, ISO13485, RoHS docs

|

|

Sample Reports

|

Review cross-sections, impedance tests, AOI images

|

|

Engineering Response Times

|

Email a stackup question—are answers technical and fast?

|

|

Panelization/DFM Support

|

Will they panelize your Gerbers for optimization?

|

|

Volume Flexibility

|

Can they scale from 5 prototypes to 10k+ boards?

|

|

Post-Sales Service

|

Warranty, RMA, or root-cause analysis when problems arise

|

Applications of 4-Layer PCBs in Modern Electronics

The versatility, reliability, and performance benefits of 4-layer PCBs have made them the preferred choice for a broad spectrum of modern electronic applications. Their optimal blend of signal integrity, EMI reduction, routing density, and power delivery makes the four-layer printed circuit board a foundational technology in nearly every market segment where complexity, size, or electrical performance matter.

1. Consumer Electronics

- Wearables and Smart Devices Compact fitness trackers, smartwatches, and portable health monitors rely on four-layer PCB stackups to accommodate advanced microcontrollers, wireless radios, and sensor arrays within tiny form factors.

- Routers and Access Points High-speed networking devices use 4-layer PCB manufacturing processes for precise controlled impedance, ensuring signal quality for USB 3.x, Wi-Fi, and Ethernet interfaces.

- Gaming Consoles and Home Hubs Dense PC motherboards, controllers, and high-speed data devices benefit from multi-plane stackups to reduce noise, improve thermal management, and support advanced CPUs and discrete graphics.

2. Automotive Electronics

- Electronic Control Units (ECUs) Modern vehicles use dozens of ECUs, all requiring robust, EMI-immune multilayer PCBs for controlling powertrains, airbags, braking, and infotainment.

- Advanced Driver Assistance Systems (ADAS) 4-layer PCB designs underpin radar, LIDAR, and high-speed camera interfaces where consistent signal delivery and thermal performance are mission-critical.

- Battery Management and Power Control In EVs and hybrids, four-layer stackups handle high-current distribution, fault isolation, and reliable communication between battery modules.

3. Industrial & Automation

- Gateways and Communication Modules Industrial control networks (Ethernet, Profibus, Modbus) employ 4-layer printed circuit boards for rugged interfaces and reliable power.

- PLC and Robotics Controllers Dense layouts, mixed-signal design, and power isolation are achieved efficiently with multilayer stackups, improving machine uptime and reducing noise.

- Test & Measurement Instruments Precision analog and high-speed digital circuits require controlled impedance routing, crosstalk mitigation, and careful PDN engineering—all strengths of the four-layer PCB.

4. Medical Devices

- Portable Diagnostics and Monitors From pulse oximeters to mobile ECGs, 4-layer PCB fabrication supports miniaturization, mixed-signal design, and reliable operation in safety-critical healthcare products.

- Implantable and Body-Worn Instruments Strict biocompatibility, reliability, and low-EMI are made possible through well-designed stackups, certified to ISO13485 and IPC-A-610 Class 3.

5. IoT, Telecom, and Data Infrastructure

- Gateways, Sensors, and Edge Devices Low-power but high-density IoT products achieve reliability and performance via modern multilayer stackups, often integrating wireless, analog, and high-speed digital in a single compact board.

- High-Speed Backplanes and Modules Routers, switches, and servers rely on 4-layer and more complex boards for fast, noise-immune signaling and robust power rail architecture.

Table: Example Applications and Stackup Advantages

|

Application Type

|

4-Layer PCB Benefits

|

Typical Key Requirements

|

|

Wearables/Consumer

|

Compact, low EMI, high density

|

Controlled impedance, miniaturization

|

|

Automotive ECU/ADAS

|

Reliability, EMI immunity

|

ISO/vehicle standards, robust power, SI, EMC

|

|

Industrial Robots

|

Signal integrity, durability

|

Power/ground planes, increased routing space

|

|

Medical Devices

|

Noise reduction, long life

|

ISO13485, clean ground/power, low EMI

|

|

IoT Gateways

|

RF/digital integration, small size

|

Clean stackup, flexible pinout, reliability

|

Frequently Asked Questions (FAQ)

1. How does a 4-layer PCB improve EMI performance?

A 4-layer PCB enables a solid ground plane directly beneath signal layers, creating highly effective return paths for high-speed currents. This minimizes loop area, sharply reduces EMI emissions, and shields sensitive signals from interference. Unlike 2-layer boards, the internal planes in four-layer stackups absorb and redirect radiated noise, helping devices pass EMC compliance on the first try.

2. When should I upgrade from 2-layer to 4-layer PCB?

Upgrade to 4-layer PCB if:

- You need to run high-speed digital buses (USB, HDMI, PCIe, DDR, etc).

- Your design is failing radiated/conducted EMI compliance.

- You struggle to fit dense modern parts without excessive vias or “rat’s nest” routing.

- Stable power distribution and low ground-bounce are essential.

3. What copper thickness should I specify for my 4-layer PCB?

- 1 oz (35µm) per layer is standard—adequate for most digital and mixed-signal designs.

- 2 oz or more is recommended for high-current paths or demanding thermal requirements (e.g., power supplies, LED drivers).

- Always specify copper weight for both signal and plane layers separately in your stackup.

4. Can 4-layer PCBs support controlled impedance for high-speed signals?

Yes! With proper stackup design and close control of dielectric thickness, 4-layer PCBs are ideal for 50Ω single-ended and 90–100Ω differential pairs. Modern board houses will fabricate test coupons to measure and certify impedance to within ±10% (per IPC-2141A).

5. What are the main drivers of 4-layer PCB manufacturing cost?

- Core/prepreg material types (FR-4 vs. high-frequency, high-TG, etc)

- Board size, total quantity, and panel utilization

- Layer count and copper thickness

- Minimum trace/space and via diameter

- Surface finish (ENIG, HASL, OSP, immersion silver/tin)

- Certifications (UL, ISO, RoHS, Automotive/Medical)

Conclusion & Key Takeaways

Mastering the 4-layer PCB manufacturing process—from careful stackup design through meticulous fabrication and thorough testing—empowers modern electronics creation with confidence, precision, and speed. The four-layer PCB remains a “sweet spot” in balancing complexity, electrical performance, and total installed cost, delivering robust results for everything from compact consumer gadgets to automotive ECUs and medical diagnostics.

Recap: What Makes 4-Layer PCBs Essential?

- Signal Integrity & EMI Suppression: The distinct inner ground and power planes in a four-layer PCB stackup secure tight signal reference, reduce crosstalk, and meet today’s demanding EMC standards.

- Higher Routing Density: Double the copper layers versus 2-layer PCBs meaningfully increases component options and makes denser, smaller products a reality without routing nightmares.

- Reliable Power Distribution: Dedicated planes ensure low-resistance, low-inductance delivery to every component—enabling stable power rails and supporting high-performance processors or analog circuits.

- Cost-Efficient Complexity: 4-layer fabrication and assembly are now mature, affordable, and globally available—allowing rapid, scalable production whether you need five PCBs or fifty thousand.

Golden Rules for Four-Layer PCB Excellence

Always define your stackup and impedance needs up front. Early planning (with manufacturer collaboration) averts downstream surprises and ensures your high-speed or analog nets perform as designed.

Protect planes and maintain solid returns. Avoid unnecessary slots/cutouts in ground/power planes. Follow IPC-2221/2222 best practices for uninterrupted planes and correct minimum clearances.

Leverage professional PCB CAD tools. Use Altium, Eagle, KiCad, or your suite of choice, and always double-check Gerber/drill exports for clarity and completeness.

Demand and verify quality control. Choose suppliers with AOI, in-circuit and impedance testing, and ISO/UL/IPC certifications. Require sample cross-sections or impedance coupons for high-reliability designs.

Optimize for panel and process. Work with your manufacturer to tailor your layout for their panel sizes and preferred processes—this often reduces your price by 10–30% without any performance compromise.

Hot News

Hot News