With the rapid change in the electronics industry today, demand for compact, reliable, and highly functional devices is increasing dramatically. Manufacturers face a continuous challenge to develop electronics that are smaller, lighter, and more durable across a wide range of industries including wearables, medical instruments, and aerospace technology, among others. This is exactly the point at which a rigid flex PCB becomes the hero of the story - it is a great innovative solution that brings together the benefits of both rigid and flexible circuit technologies. We at King Field, provide innovative rigid flex PCB solutions that are specially made to cater to the highly demanding compact electronics needs of today. And what exactly is so great about rigid flex PCBs? Let us uncover it.

Understanding Rigid Flex PCB Fabrication

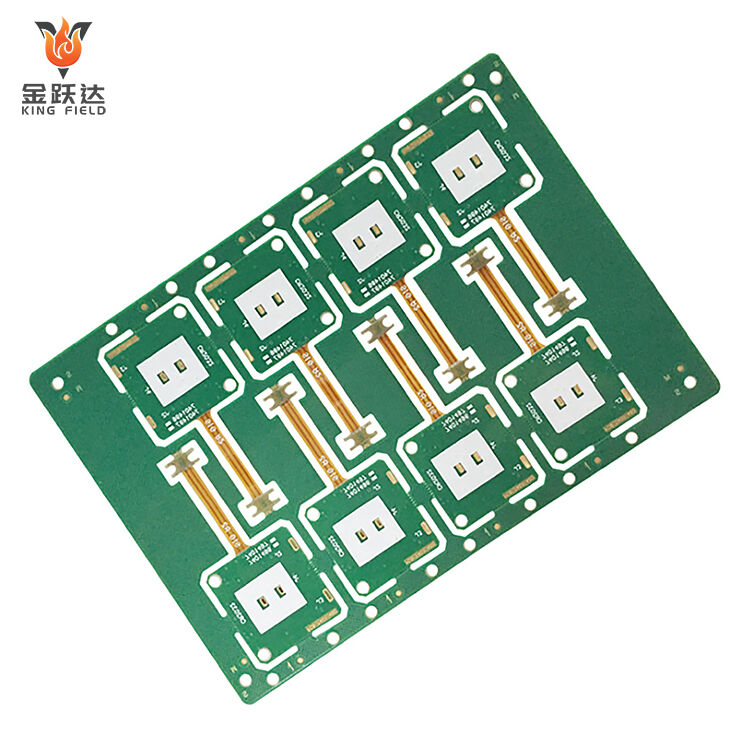

The technique of making rigid flex PCB is to combine two different circuits in one design - a rigid part gives the whole structure strength and the flexible part permits the circuit to be bent or folded. Unlike normal PCBs that are either rigid or flexible, rigid flex PCBs combine both features in one seamless element and thus they can be designed in complex three-dimensional shapes.

The manufacturing of the product is very elaborate and involves embedding several layers of copper trace conductors, polyimide insulating films, and rigid FR-4 materials. These layers are tightly bonded to one another which means basically very good electrical performance, mechanical strength, and reliability for a long time. Just like any other top-class company, King Field also uses the latest technology in the fabrication process to guarantee uniform quality even in very dense designs.

Space-Saving Design for Compact Electronics

The reason engineers very often choose rigid flex PCBs among others is that such PCBs can really help save quite a lot of space. It goes without saying that in compact electronics, every millimeter makes a difference. In the case of a typical 2- or 3-board assembly, there have to be extra connectors and wiring which inevitably add to the bulk, the weight, and increase the likelihood of the product failing.

By integrating rigid and flexible sections in one single board, rigid flex PCBs remove the need for these additional connections. Flexible areas can be wrapped around corners, parts, and fold into small housing which results in greatly reducing the size of the whole unit. Smartphones, smartwatches, fitness wearables, and compact medical devices are examples where such a space-saving feature is very crucial.

Enhanced Durability and Reliability

Besides space saving, durability is yet another very significant benefit that can be enjoyed from a rigid flex PCB. One of the weaknesses of the flexible areas in traditional flex circuits is that they tend to get damaged quite easily especially when used in highly dynamic situations where there is constant bending. Since rigid flex PCBs use the combination of rigid parts for structural stability and also flexible parts for movement which means lower mechanical stress in those parts.

On top of that, this structural feature allows the device to be very reliable when it has to be used in vibration, shock, or any other harsh environment situation. Here the level of reliability is basically a matter of life and death for medical instruments and military devices that also happen to be used in aerospace, of course. King Field’s rigorous test for their rigid flex PCBs includes thermal cycling, vibration analysis, and bend testing, thus the products are very stable and can be trusted even under very harsh conditions.

Simplified Assembly and Reduced Manufacturing Costs

The complexity of compact electronic devices is often exaggerated with the use of multiple boards, connectors, and interconnect cables. Apart from increasing the risk of assembly mistakes, such complexity also is a very significant driver of higher manufacturing costs. Rigid flex PCB fabrication solves both problems by effectively merging several boards into one single unit.

This means there will be less connections and solder joints, and the overall assembly process will be simpler. Making this process more efficient lowers the chances of connection failure and thereby results in shorter production cycles. Even though the initial fabrication cost of rigid flex PCBs can be more than that of traditional PCBs, the total cost will be significantly less due to the savings in assembly, testing, and more reliable performance over the long term.

Outstanding Electrical Performance

Besides, when it comes to electrical performance, rigid flex PCBs are truly leading the pack. The compact design reduces the number of connectors and inter-board traces, which are usually the biggest sources of signal degradation and electromagnetic interference (EMI). This ensures a cleaner signal transmission and essentially a better overall performance, particularly in the case of high-frequency or high-speed applications.

In addition to this, rigid flex PCBs make it possible to precisely control trace geometry and impedance, hence facilitating very complex designs such as high-density interconnects (HDI), differential signaling, and multilayer configurations. For modern consumer electronics, telecommunications, and industrial automation, these electrical benefits are indispensable for dependable operation even in very tight spaces.

Application Versatility

Just think of the vast range of products from military and aerospace technology, healthcare devices to the consumer electronics; rigid flex PCB fabrication is the only technology, which can provide such versatility. Designers take the help of rigid flex PCBs to develop complex 3D circuits that they cannot accomplish even if they use only conventional rigid PCBs. These characteristics of the rigid flex PCBs can be used to make foldable smartphones, diagnostic instruments that are not only high in performance but also small, and wearable sensors that are hardly noticed in everyday use.

At King Field, we have helped our clients, who are from different sectors of the economy, to accomplish their specific mechanical and electrical needs through our custom-made rigid flex solutions. Our proficiency in the field enables us to deliver a product that not only meets the device physical constraints but also adheres to the performance standards required.

Sustainability and Long-Term Value

Last but not the least, rigid flex PCBs will help the manufacturers to practice smart sustainability and also add more value for longer use. By using less individual boards, connectors, and cables, there is also less waste of materials and less packaging. Moreover, fewer interconnections naturally mean less maintenance, and there will also be fewer replacement parts over the product’s life cycle.

For any company that is striving to balance a high-yield, high-performance type of product and their responsibility towards the environment, rigid flex PCB fabrication is a great forward-looking option. We, King Field, remain committed to green and sustainable manufacturing corridors and we use materials and processes that have the least negative impact on the environment but at the same time, the products have a very long life.

Conclusion

The use of rigid flex PCB fabrication, in the era when miniaturized high-performance electronics dominate the market, is a very good idea basically because of the different requisites of compact devices that it can satisfy simultaneously. The inseparable properties of the product, namely space-saving, durability through increased strength, ease of assembly, outstanding electrical features, and a broad range of applications, make it an absolute necessity for the modern electronics designer.

The manufacturers and the innovators who are looking forward to the day when they will be able to make infinitely small electronics that can achieve anything – that day we believe is not so far off – will do well by securing the services of an expert like King Field who is good at delivering quality, reliable, and cutting-edge rigid flex solutions. With the device size becoming smaller as the years go by and at the same time the performance requirements are getting higher, one can only imagine the help that rigid flex PCB fabrication can give in taking the future of electronics to the next level.